Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

OPERATION |

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

8. DIGITAL METER AND DISPLAY SWITCH– A 3- | • When the Current Control Switch is in either LOCAL | |||||||||||||||||||

digit LED meter is used to monitor the preset and |

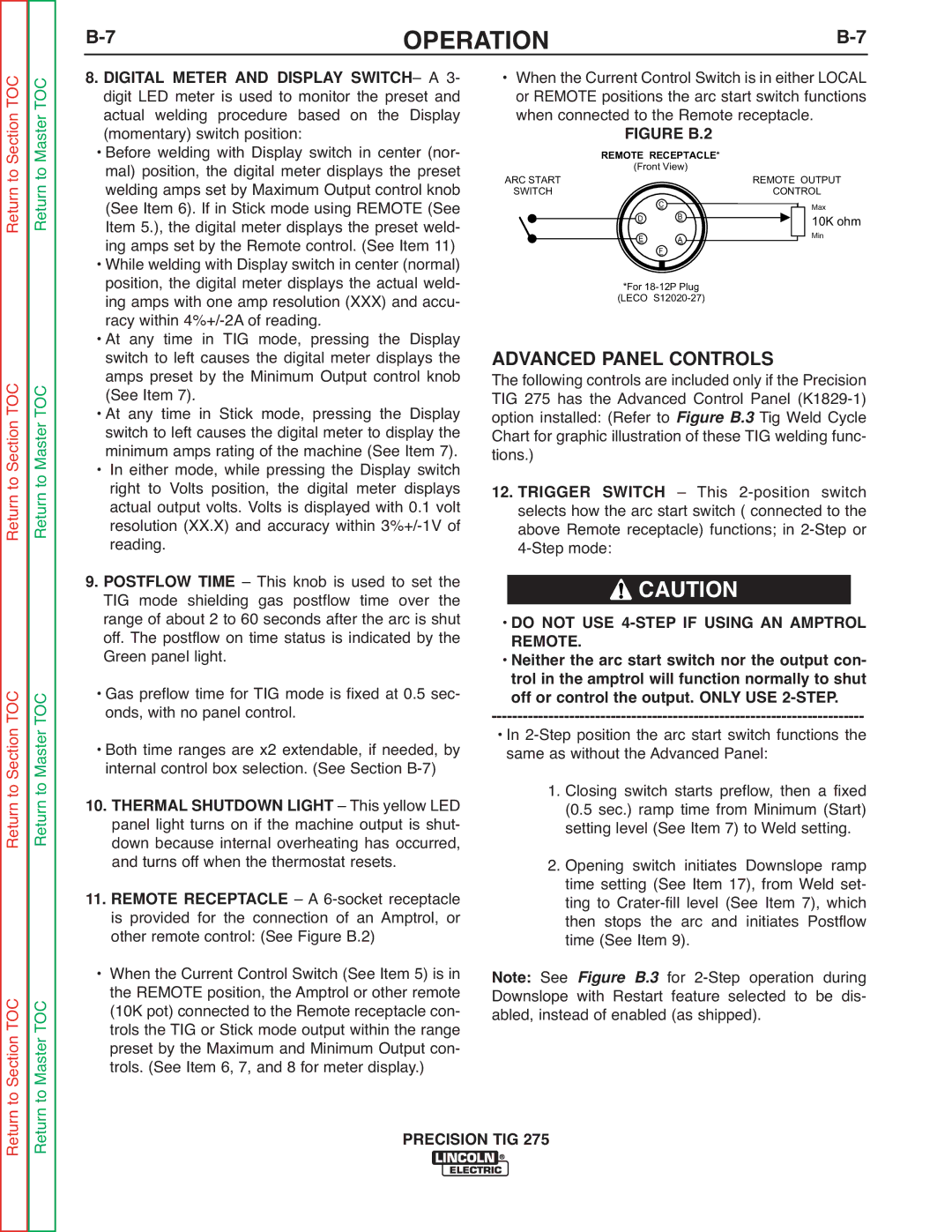

| or REMOTE positions the arc start switch functions | ||||||||||||||||||

actual welding procedure based on the Display |

| when connected to the Remote receptacle. | ||||||||||||||||||

(momentary) switch position: |

|

|

|

| FIGURE B.2 |

|

|

|

|

|

|

|

|

| ||||||

• Before welding with Display switch in center (nor- |

|

|

| REMOTE RECEPTACLE* |

|

|

|

|

|

|

|

|

| |||||||

mal) position, the digital meter displays the preset | ARC START |

| (Front View) |

| REMOTE OUTPUT |

| ||||||||||||||

welding amps set by Maximum Output control knob |

| SWITCH |

|

|

|

|

|

|

|

| CONTROL |

| ||||||||

(See Item 6). If in Stick mode using REMOTE (See |

|

|

|

|

| C |

|

|

|

|

|

|

|

| Max |

| ||||

|

|

|

|

| B |

|

|

|

|

|

|

| ||||||||

|

|

|

|

| D |

|

|

|

|

|

| 10K ohm | ||||||||

Item 5.), the digital meter displays the preset weld- |

|

|

|

|

| E |

|

|

|

|

|

|

|

| Min | |||||

|

|

|

|

| A |

|

|

|

|

|

| |||||||||

ing amps set by the Remote control. (See Item 11) |

|

|

|

|

| F |

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

• While welding with Display switch in center (normal) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

position, the digital meter displays the actual weld- |

|

|

|

| *For |

|

|

|

|

|

|

|

|

| ||||||

ing amps with one amp resolution (XXX) and accu- |

|

|

|

| (LECO |

|

|

|

|

|

|

|

|

| ||||||

racy within |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

• At any time in TIG mode, pressing the Display |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

switch to left causes the digital meter displays the | ADVANCED PANEL CONTROLS | |||||||||||||||||||

amps preset by the Minimum Output control knob | The following controls are included only if the Precision | |||||||||||||||||||

(See Item 7). | in Stick mode, pressing the Display | TIG 275 has the Advanced Control Panel | ||||||||||||||||||

• At any time | option installed: (Refer to Figure B.3 Tig Weld Cycle | |||||||||||||||||||

switch to left causes the digital meter to display the | Chart for graphic illustration of these TIG welding func- | |||||||||||||||||||

minimum amps rating of the machine (See Item 7). | tions.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

• In either mode, while pressing the Display switch |

|

|

|

|

| – This | ||||||||||||||

right to Volts position, the digital meter displays | 12. TRIGGER SWITCH | |||||||||||||||||||

actual output volts. Volts is displayed with 0.1 volt |

| selects how the arc start switch ( connected to the | ||||||||||||||||||

resolution (XX.X) and accuracy within |

| above Remote receptacle) functions; in | ||||||||||||||||||

reading. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

9. POSTFLOW TIME – This knob is used to set the |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

| CAUTION |

|

| |||||||||||||

TIG mode shielding gas postflow time over the |

|

|

|

|

|

| ||||||||||||||

range of about 2 to 60 seconds after the arc is shut | • DO NOT USE | |||||||||||||||||||

off. The postflow on time status is indicated by the |

| REMOTE. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Green panel light. | • Neither the arc start switch nor the output con- | |||||||||||||||||||

• Gas preflow time for TIG mode is fixed at 0.5 sec- |

| trol in the amptrol will function normally to shut | ||||||||||||||||||

| off or control the output. ONLY USE | |||||||||||||||||||

onds, with no panel control. | ||||||||||||||||||||

• Both time ranges are x2 extendable, if needed, by | • In | |||||||||||||||||||

same as without the Advanced Panel: | ||||||||||||||||||||

internal control box selection. (See Section |

|

| 1. Closing switch starts preflow, then a fixed | |||||||||||||||||

10. THERMAL SHUTDOWN LIGHT – This yellow LED |

|

| ||||||||||||||||||

|

| (0.5 sec.) ramp time from Minimum (Start) | ||||||||||||||||||

panel light turns on if the machine output is shut- |

|

| setting level (See Item 7) to Weld setting. | |||||||||||||||||

down because internal overheating has occurred, |

|

| ||||||||||||||||||

and turns off when the thermostat resets. |

|

| 2. Opening switch initiates Downslope ramp | |||||||||||||||||

11. REMOTE RECEPTACLE – A |

|

| time setting (See Item 17), from Weld set- | |||||||||||||||||

|

| ting to | ||||||||||||||||||

is provided for the connection of an Amptrol, or |

|

| then stops the arc and initiates Postflow | |||||||||||||||||

other remote control: (See Figure B.2) |

|

| time (See Item 9). |

|

|

|

|

|

|

|

|

| ||||||||

• When the Current Control Switch (See Item 5) is in | Note: See | F gure B.3 | for | |||||||||||||||||

the REMOTE position, the Amptrol or other remote | Downslope | with Restart | feature | selected to be dis- | ||||||||||||||||

(10K pot) connected to the Remote receptacle con- | abled, instead of enabled (as shipped). | |||||||||||||||||||

trols the TIG or Stick mode output within the range | ||||||||||||||||||||

preset by the Maximum and Minimum Output con- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

trols. (See Item 6, 7, and 8 for meter display.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

PRECISION TIG 275