Return to Section TOC Return to Master TOC

F-60 TROUBLESHOOTING & REPAIRF-60

SCR REMOVAL AND REPLACEMENT (continued)

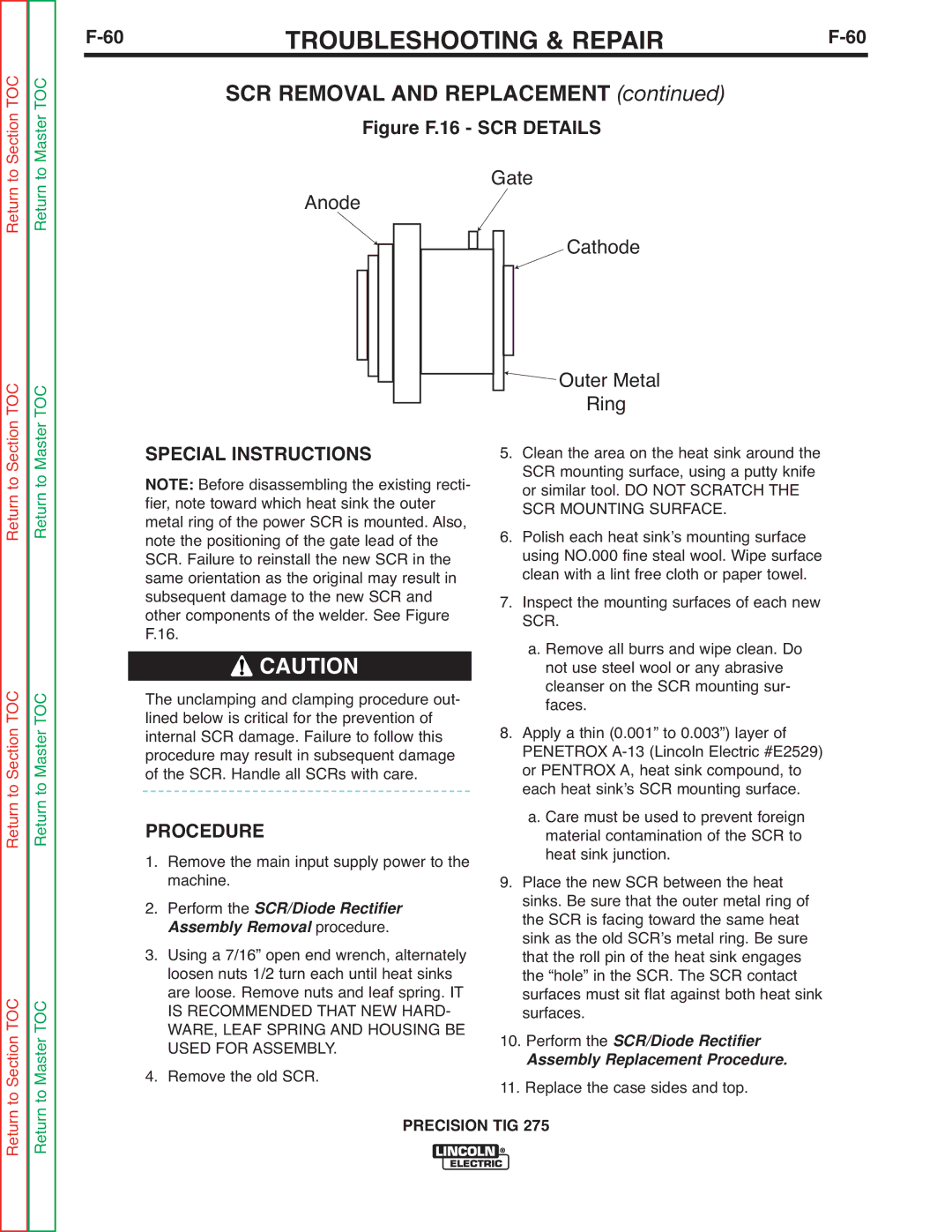

Figure F.16 - SCR DETAILS

Gate

Cathode

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Outer Metal |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Ring |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

SPECIAL INSTRUCTIONS |

|

| |||||||||||||

5. | Clean the area on the heat sink around the | ||||||||||||||

NOTE: Before disassembling the existing recti- |

|

| SCR mounting surface, using a putty knife | ||||||||||||

fier, note toward which heat sink the outer |

|

| or similar tool. DO NOT SCRATCH THE | ||||||||||||

metal ring of the power SCR is mounted. Also, | 6. | SCR MOUNTING SURFACE. | |||||||||||||

note the positioning of the gate lead of the | Polish each heat sinkʼs mounting surface | ||||||||||||||

SCR. Failure to reinstall the new SCR in the |

|

| using NO.000 fine steal wool. Wipe surface | ||||||||||||

same orientation as the original may result in | 7. | clean with a lint free cloth or paper towel. | |||||||||||||

subsequent damage to the new SCR and | Inspect the mounting surfaces of each new | ||||||||||||||

other components of the welder. See Figure |

|

| SCR. | ||||||||||||

F.16. |

|

|

|

|

|

|

|

|

|

|

|

|

| a. Remove all burrs and wipe clean. Do | |

|

| CAUTION |

|

|

| not use steel wool or any abrasive | |||||||||

|

|

|

| cleanser on the SCR mounting sur- | |||||||||||

The unclamping and clamping procedure out- |

|

| |||||||||||||

lined below is critical for the prevention of | 8. | faces. | |||||||||||||

internal SCR damage. Failure to follow this | Apply a thin (0.001” to 0.003”) layer of | ||||||||||||||

procedure may result in subsequent damage |

|

| PENETROX | ||||||||||||

of the SCR. Handle all SCRs with care. |

|

| or PENTROX A, heat sink compound, to | ||||||||||||

|

| each heat sinkʼs SCR mounting surface. | |||||||||||||

PROCEDURE |

|

|

|

|

|

|

|

|

|

|

|

| a. Care must be used to prevent foreign | ||

|

|

|

|

|

|

|

|

|

|

|

| material contamination of the SCR to | |||

1. | Remove the main input supply power to the | 9. | heat sink junction. | ||||||||||||

2. | machine. |

|

|

|

|

|

|

|

|

|

|

| Place the new SCR between the heat | ||

Perform the SCR/Diode Rectifier |

|

| sinks. Be sure that the outer metal ring of | ||||||||||||

| A sembly Removal | procedure. |

|

| the SCR is facing toward the same heat | ||||||||||

3. |

|

|

|

| sink as the old SCRʼs metal ring. Be sure | ||||||||||

Using a 7/16” open end wrench, alternately |

|

| that the roll pin of the heat sink engages | ||||||||||||

| loosen nuts 1/2 turn each until heat sinks |

|

| the “hole” in the SCR. The SCR contact | |||||||||||

| are loose. Remove nuts and leaf spring. IT |

|

| surfaces must sit flat against both heat sink | |||||||||||

| IS RECOMMENDED THAT NEW HARD- |

|

| surfaces. | |||||||||||

| WARE, LEAF SPRING AND HOUSING BE | 10. Perform the SCR/Diode Rectifier | |||||||||||||

4. | USED FOR ASSEMBLY. |

|

| Assembly Replacement Procedure. | |||||||||||

Remove the old SCR. | 11. Replace the case sides and top. | ||||||||||||||

|

|

|

|

|

|

|

| PRECISION TIG 275 | |||||||