Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

|

|

| INSTALLATION |

|

|

|

|

|

|

| ||||||

1. Connect the terminal marked |

|

| (below the recon- |

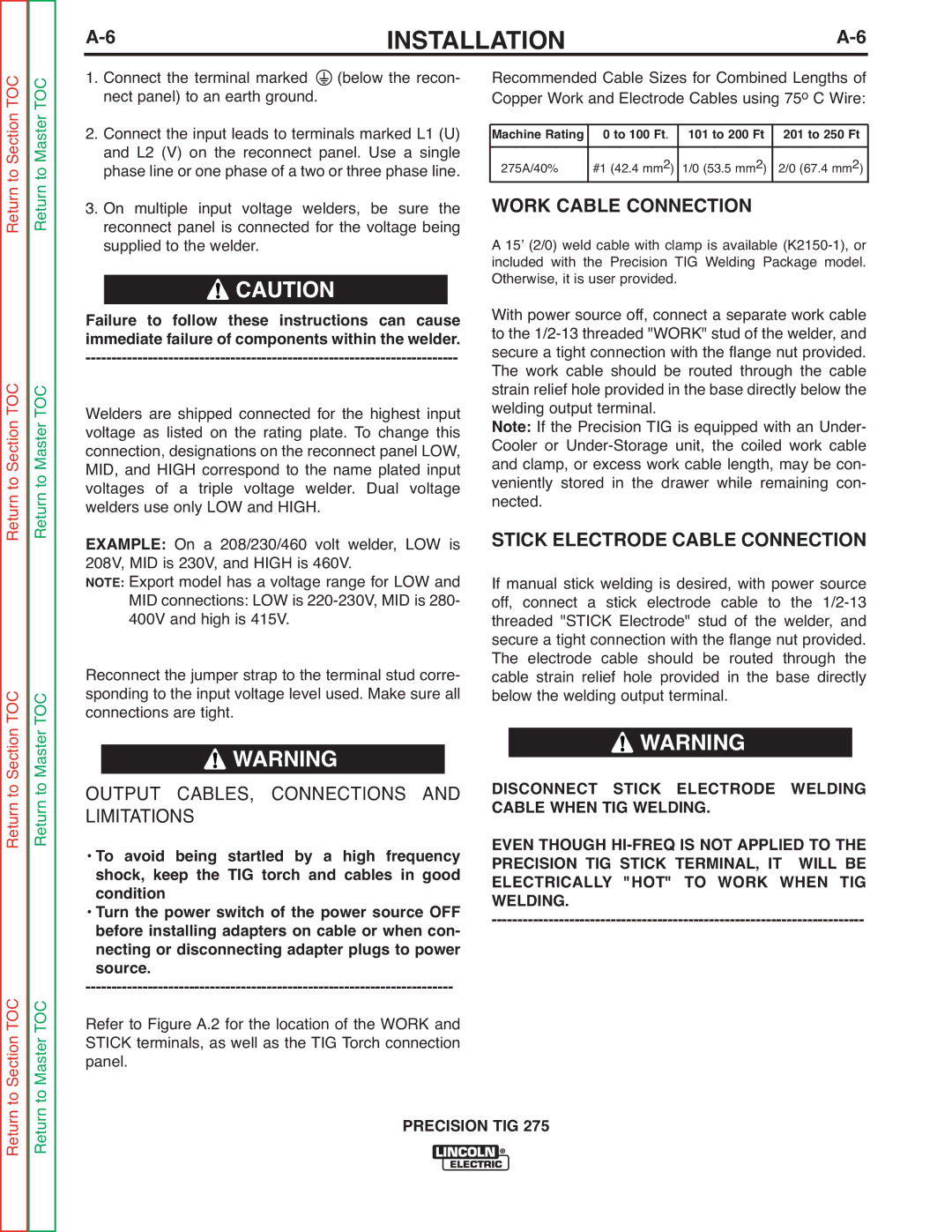

| Recommended Cable Sizes for Combined Lengths of |

| ||||||||||

| nect panel) to an earth ground. |

|

|

| Copper Work and Electrode Cables using 75o C Wire: |

| ||||||||||

2. Connect the input leads to terminals marked L1 (U) |

| Machine Rating |

| 0 to 100 Ft. |

| 101 to 200 Ft |

|

| 201 to 250 Ft |

| ||||||

|

|

|

|

| ||||||||||||

| and L2 (V) on the reconnect panel. Use a single |

|

|

|

|

|

|

|

|

|

| |||||

|

| 275A/40% |

| #1 (42.4 mm2) |

| 1/0 (53.5 mm2) |

|

| 2/0 (67.4 mm2) |

| ||||||

| phase line or one phase of a two or three phase line. |

|

|

|

|

|

| |||||||||

3. On multiple input voltage welders, be sure the |

| WORK CABLE CONNECTION |

|

| ||||||||||||

| reconnect panel is connected for the voltage being |

| included with the Precision TIG Welding Package model. |

| ||||||||||||

| supplied to the welder. |

|

|

|

| |||||||||||

|

| CAUTION |

|

|

| A 15ʼ (2/0) weld cable with clamp is available |

| |||||||||

|

|

|

|

| Otherwise, it is user provided. |

|

| |||||||||

Failure to follow these instructions can cause |

| With power source off, connect a separate work cable |

| |||||||||||||

| to the |

| ||||||||||||||

immediate failure of components within the welder. |

| secure a tight connection with the flange nut provided. |

| |||||||||||||

| The work cable should be routed through the cable |

| ||||||||||||||

Welders are shipped connected for the highest input |

| strain relief hole provided in the base directly below the |

| |||||||||||||

| welding output terminal. |

|

|

|

|

|

| |||||||||

voltage as listed on the rating plate. To change this |

| Note: If the Precision TIG is equipped with an Under- |

| |||||||||||||

connection, designations on the reconnect panel LOW, |

| Cooler or |

| |||||||||||||

MID, and HIGH correspond to the name plated input |

| and clamp, or excess work cable length, may be con- |

| |||||||||||||

voltages of a triple voltage welder. Dual voltage |

| veniently stored in the drawer while remaining con- |

| |||||||||||||

welders use only LOW and HIGH. |

|

|

| nected. |

|

|

|

|

|

|

|

| ||||

EXAMPLE: On a 208/230/460 volt welder, LOW is |

| STICK ELECTRODE CABLE CONNECTION |

| |||||||||||||

208V, MID is 230V, and HIGH is 460V. |

| If manual stick welding is desired, with power source |

| |||||||||||||

NOTE: Export model has a voltage range for LOW and |

|

| ||||||||||||||

| MID connections: LOW is |

| off, connect a stick electrode cable to the |

| ||||||||||||

| 400V and high is 415V. |

|

|

| threaded "STICK Electrode" stud of the welder, and |

| ||||||||||

|

|

|

|

|

|

|

| secure a tight connection with the flange nut provided. |

| |||||||

Reconnect the jumper strap to the terminal stud corre- |

| The electrode cable should be routed through the |

| |||||||||||||

| cable strain relief hole provided in the base directly |

| ||||||||||||||

sponding to the input voltage level used. Make sure all |

| below the welding output terminal. |

|

| ||||||||||||

| connections are tight.WARNING |

|

|

|

| WARNING |

|

| ||||||||

O | UTPUT CABLES, CONNECTIONS AN | D |

| DISCONNECT STICK | ELECTRODE | WELDING |

| |||||||||

LIMITATIONS |

|

|

| CABLE WHEN TIG WELDING. |

|

| ||||||||||

• To avoid being startled by a high frequency |

| EVEN THOUGH |

| |||||||||||||

shock, keep the TIG torch and cables in good |

| PRECISION TIG STICK TERMINAL, IT WILL BE |

| |||||||||||||

condition |

|

|

| ELECTRICALLY "HOT" TO WORK WHEN TIG |

| |||||||||||

• Turn the power switch of the power source OFF |

| WELDING. |

|

|

|

|

|

|

|

| ||||||

before installing adapters on cable or when con- |

| |||||||||||||||

necting or disconnecting adapter plugs to power |

|

|

|

|

|

|

|

|

|

| ||||||

source. |

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

| |||||||

Refer to Figure A.2 for the location of the WORK and STICK terminals, as well as the TIG Torch connection panel.

PRECISION TIG 275