Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

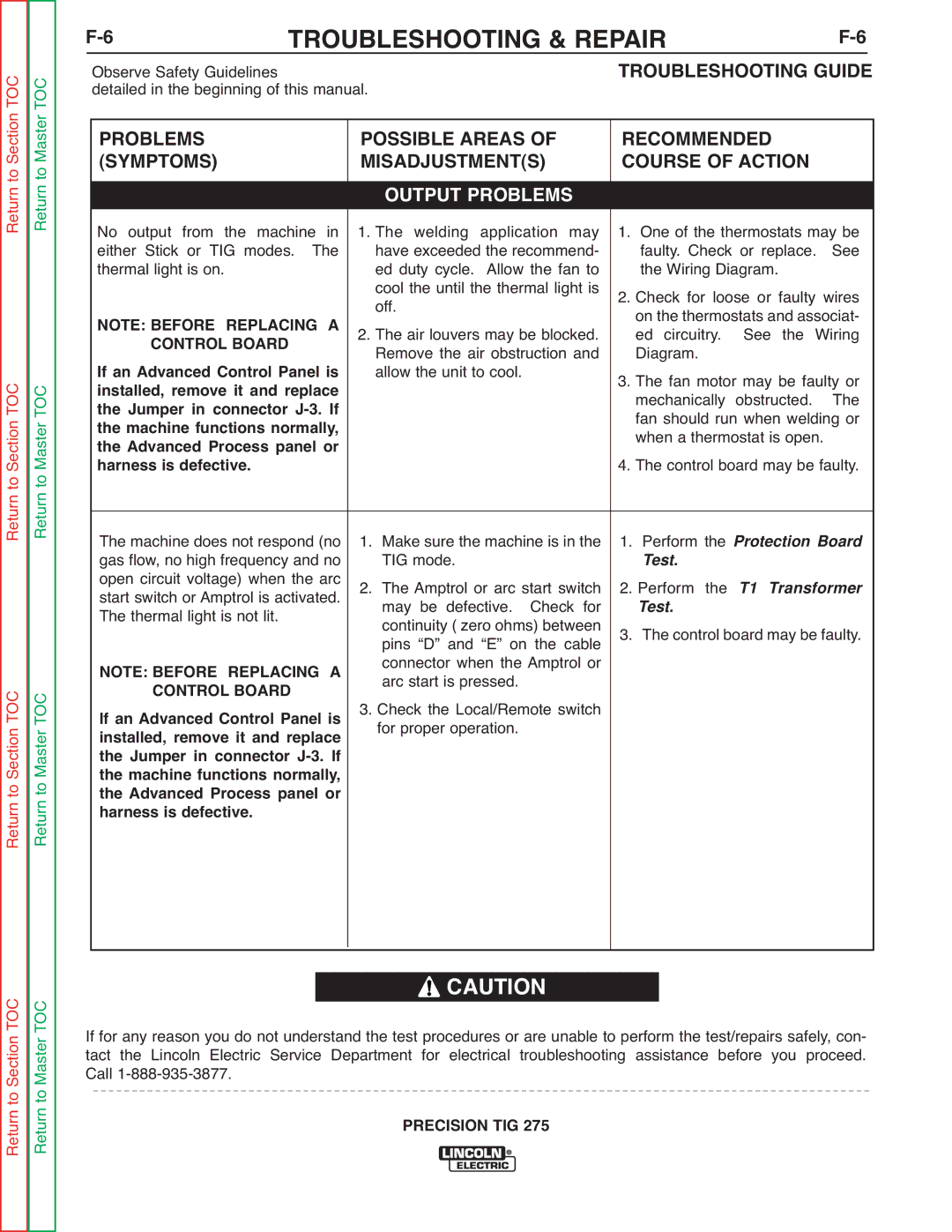

| TROUBLESHOOTING & REPAIR |

| |||||

| Observe Safety Guidelines |

|

| TROUBLESHOOTING GUIDE | |||

| detailed in the beginning of this manual. |

|

|

| |||

| PROBLEMS |

|

| POSSIBLE AREAS OF | RECOMMENDED |

| |

| (SYMPTOMS) |

|

| MISADJUSTMENT(S) | COURSE OF ACTION |

| |

|

|

|

| OUTPUT PROBLEMS |

|

|

|

| No output from the machine in | 1. The welding application may | 1. One of the thermostats may be | ||||

| either Stick or TIG | modes. The | have exceeded the recommend- | faulty. Check or replace. | See | ||

| thermal light is on. |

|

| ed duty cycle. Allow the fan to | the Wiring Diagram. |

| |

|

|

|

| cool the until the thermal light is | 2. Check for loose or faulty wires | ||

| NOTE: BEFORE REPLACING A | off. | on the thermostats and associat- | ||||

| 2. The air louvers may be blocked. | ed circuitry. | See the Wiring | ||||

| CONTROL BOARD | Remove the air obstruction and | Diagram. |

|

| ||

| If an Advanced Control Panel is | allow the unit to cool. | 3. The fan motor may be faulty or | ||||

| installed, remove it and replace |

| |||||

| the Jumper in connector |

| mechanically | obstructed. | The | ||

| the machine functions normally, |

| fan should run when welding or | ||||

| the Advanced Process panel or |

| when a thermostat is open. |

| |||

| harness is defective. |

|

| 4. The control board may be faulty. | |||

|

|

|

| ||||

| The machine does not respond (no | 1. Make sure the machine is in the | 1. Perform the Protection Board | ||||

| gas flow, no high frequency and no | TIG mode. | Test. |

|

| ||

| open circuit voltage) when the arc | 2. The Amptrol or arc start switch | 2. Perform the | T1 Transformer | |||

| start switch or Amptrol is activated. | may be defective. Check for | Test. |

|

| ||

| The thermal light is not lit. |

| continuity ( zero ohms) between | 3. The control board may be faulty. | |||

| NOTE: BEFORE REPLACING A | pins “D” and “E” on the cable | |||||

| connector when the Amptrol or |

|

|

| |||

| CONTROL BOARD | arc start is pressed. |

|

|

| ||

| If an Advanced Control Panel is | 3. Check the Local/Remote switch |

|

|

| ||

| installed, remove it and replace | for proper operation. |

|

|

| ||

| the Jumper in connector |

|

|

|

| ||

| the machine functions normally, |

|

|

|

| ||

| the Advanced Process panel or |

|

|

|

| ||

| harness is defective. |

|

|

|

|

| |

Return to Section TOC Return to Master TOC

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call

PRECISION TIG 275