TOC TOC

THEORY OF OPERATION |

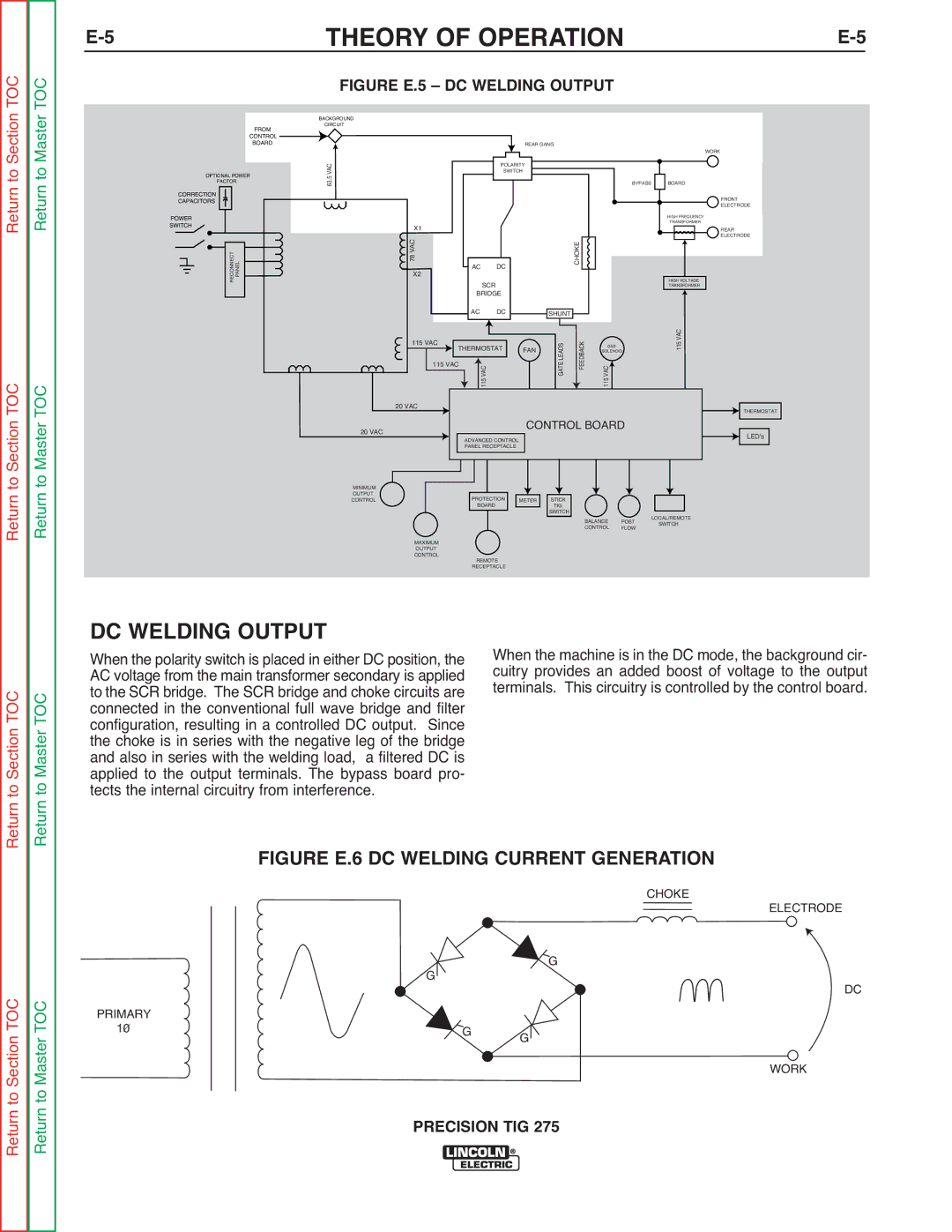

FIGURE E.5 – DC WELDING OUTPUT

Return to Section Return to Master

FROM

CONTROL

BOARD

OPTIONAL POWER

CORRECTIONFACTOR

CAPACITORS

POWER

BACKGROUND

CIRCUIT

63.5 VAC

REAR GANG | WORK |

|

POLARITY

SWITCH

BYPASS BOARD

FRONT ELECTRODE

HIGH FREQUENCY

SWITCH

PANEL

RECONNECT

X1

VAC78 X2

AC | DC | CHOKE |

| ||

| SCR |

|

BRIDGE |

| |

AC | DC | SHUNT |

TRANSFORMER

HIGH VOLTAGE TRANSFORMER

REAR ELECTRODE

115 VAC |

|

|

|

|

|

|

|

| GAS | VAC | ||

|

|

|

|

|

|

|

| FAN |

|

|

| |

|

|

|

| THERMOSTAT | GATELEADS FEEDBACK | SOLENOID | 115 | |||||

|

|

|

| |||||||||

|

|

|

|

|

| VAC |

| VAC |

| |||

| 115 VAC |

|

|

|

| 115 |

| |||||

|

|

|

|

| 115 |

|

|

|

|

| ||

|

|

|

|

|

|

|

| |||||

20 VAC

20 VAC

MINIMUM

OUTPUT

CONTROL

MAXIMUM

OUTPUT

CONTROL

|

|

|

| CONTROL BOARD |

|

|

|

| |||||||||||||

|

| ADVANCED CONTROL |

|

|

|

|

| ||||||||||||||

|

| PANEL RECEPTACLE |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| PROTECTION |

|

| METER |

| STICK |

|

|

|

|

|

|

|

| |||||

|

|

|

| BOARD |

|

|

|

|

|

| TIG |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

| SWITCH |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| BALANCE | POST | LOCAL/REMOTE | |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| CONTROL | FLOW |

| SWITCH | ||||

REMOTE

RECEPTACLE

THERMOSTAT

LED's

Return to Section TOC Return to Master TOC

to Section TOC to Master TOC

DC WELDING OUTPUT

When the polarity switch is placed in either DC position, the AC voltage from the main transformer secondary is applied to the SCR bridge. The SCR bridge and choke circuits are connected in the conventional full wave bridge and filter configuration, resulting in a controlled DC output. Since the choke is in series with the negative leg of the bridge and also in series with the welding load, a filtered DC is applied to the output terminals. The bypass board pro- tects the internal circuitry from interference.

When the machine is in the DC mode, the background cir- cuitry provides an added boost of voltage to the output terminals. This circuitry is controlled by the control board.

Return Return

FIGURE E.6 DC WELDING CURRENT GENERATION

CHOKEELECTRODE

TOC TOC

PRIMARY 10

G

![]()

![]() G

G

![]() G G

G G

DC

Return to Section Return to Master

WORK

PRECISION TIG 275