MAINTENANCE |

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Section TOC Master TOC

SERVICE PROCEDURES

Operation of the Precision TIG should be

TheCOMPONENTfollowing componentsACCESSare accessible for routine set up and periodic service without requiring removal of the case sides or roof:

• Input Reconnect Panel (refer Section A) is located behind a removable panel on the rear of the left case side. Remove the two screws (with a screwdriver or a 3/8"/ 9.5mm hex driver) on the bottom corners of this panel to remove it.

• Control Box components and PC Boards (refer Section

•

SPARK GAP ADJUSTMENT

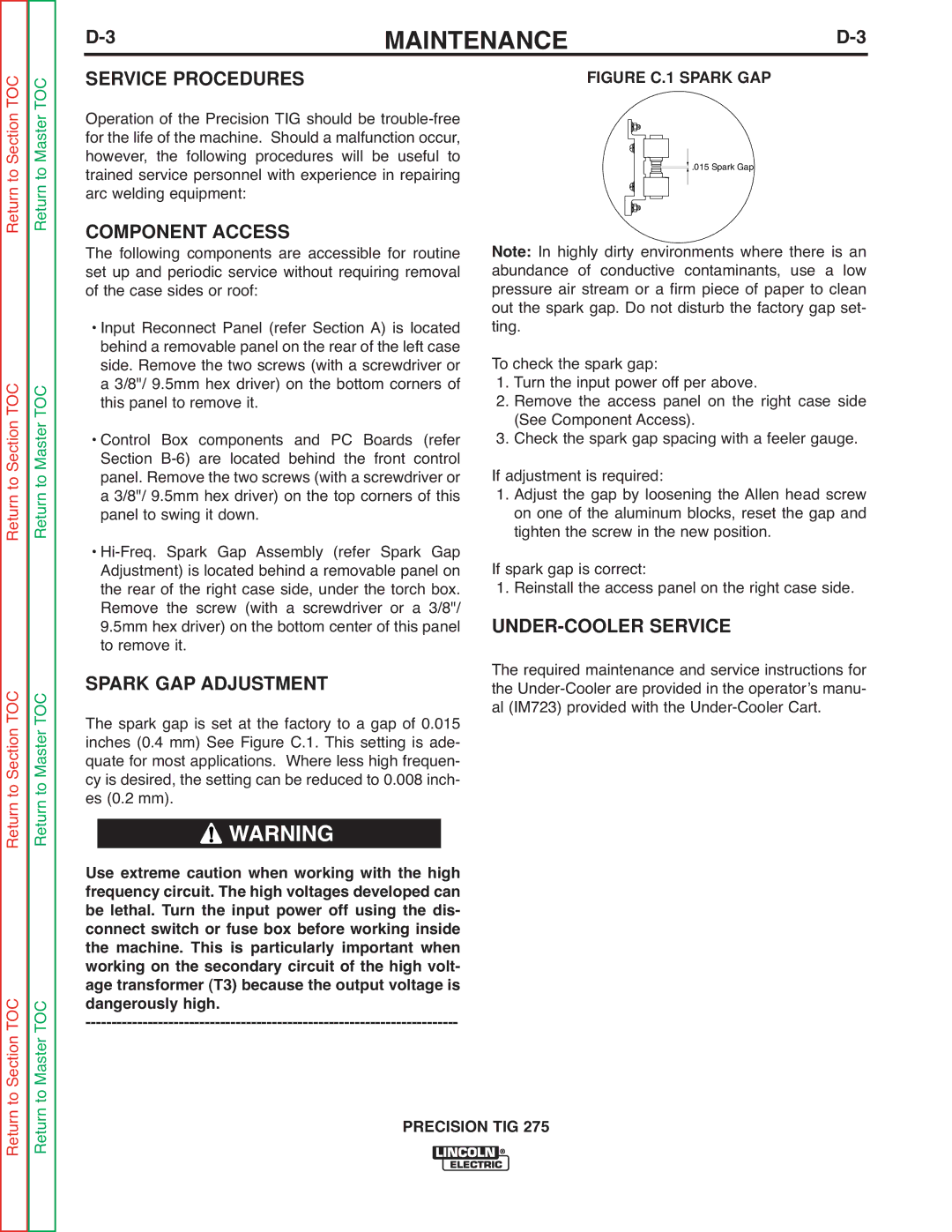

The spark gap is set at the factory to a gap of 0.015 | ||

inches (0.4 mm) See Figure C.1. This setting is ade- | ||

quate for most applications. Where less high frequen- | ||

cy is desired, the setting can be reduced to 0.008 inch- | ||

es (0.2 mm). | WARNING |

|

|

| |

Use extreme caution when working with the high | ||

frequency circuit. The high voltages developed can | ||

be lethal. Turn the input power off using the dis- | ||

connect switch or fuse box before working inside | ||

the machine. This is particularly important when | ||

working on the secondary circuit of the high volt- | ||

age transformer (T3) because the output voltage is | ||

dangerously high. |

|

|

FIGURE C.1 SPARK GAP

.015 Spark Gap |

Note: In highly dirty environments where there is an abundance of conductive contaminants, use a low pressure air stream or a firm piece of paper to clean out the spark gap. Do not disturb the factory gap set- ting.

To check the spark gap:

1. Turn the input power off per above.

2. Remove the access panel on the right case side (See Component Access).

3. Check the spark gap spacing with a feeler gauge. If adjustment is required:

1. Adjust the gap by loosening the Allen head screw on one of the aluminum blocks, reset the gap and tighten the screw in the new position.

If spark gap is correct:

1. Reinstall the access panel on the right case side.

UNDER-COOLER SERVICE

The required maintenance and service instructions for the

Return to Return to

PRECISION TIG 275