Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

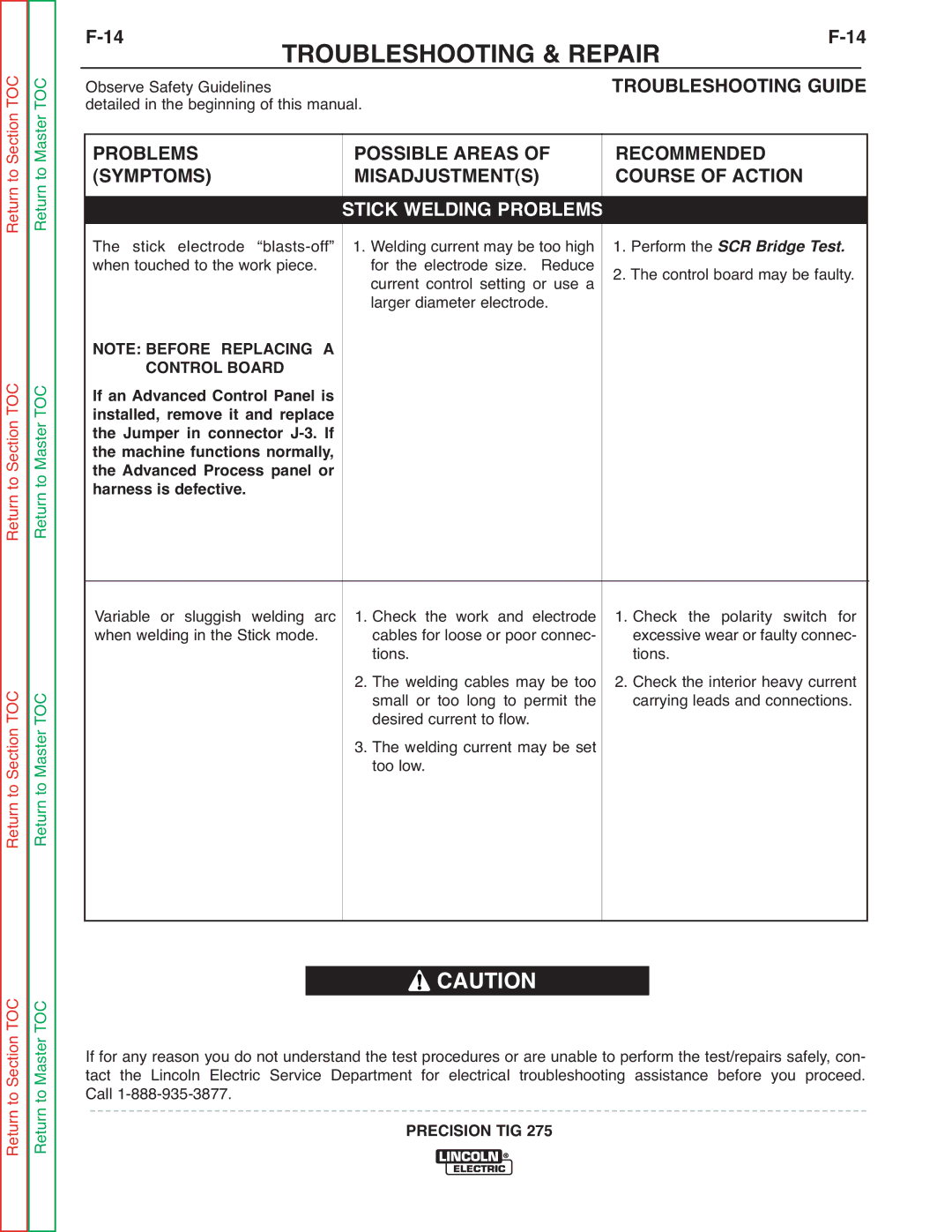

| TROUBLESHOOTING & REPAIR | ||||

| Observe Safety Guidelines |

|

| TROUBLESHOOTING GUIDE | |

| detailed in the beginning of this manual. |

|

| ||

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

|

|

|

| STICK WELDING PROBLEMS |

|

|

| The stick electrode | 1. Welding current may be too high | 1. Perform the SCR Bridge Test. | ||

| when touched to the work piece. | for the electrode size. Reduce | 2. The control board may be faulty. | ||

|

|

| current control setting or use a | ||

| NOTE: BEFORE REPLACING A | larger diameter electrode. |

|

| |

|

|

|

| ||

| CONTROL BOARD |

|

|

| |

| If an Advanced Control Panel is |

|

|

| |

| installed, remove it and replace |

|

|

| |

| the Jumper in connector |

|

|

| |

| the machine functions normally, |

|

|

| |

| the Advanced Process panel or |

|

|

| |

| harness is defective. |

|

|

|

|

Variable or sluggish welding arc 1. | Check the work and electrode | 1. | Check the polarity switch for |

when welding in the Stick mode. | cables for loose or poor connec- |

| excessive wear or faulty connec- |

2. | tions. | 2. | tions. |

The welding cables may be too | Check the interior heavy current | ||

| small or too long to permit the |

| carrying leads and connections. |

3. | desired current to flow. |

|

|

The welding current may be set |

|

| |

| too low. |

|

|

Return to Section TOC Return to Master TOC

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call