Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

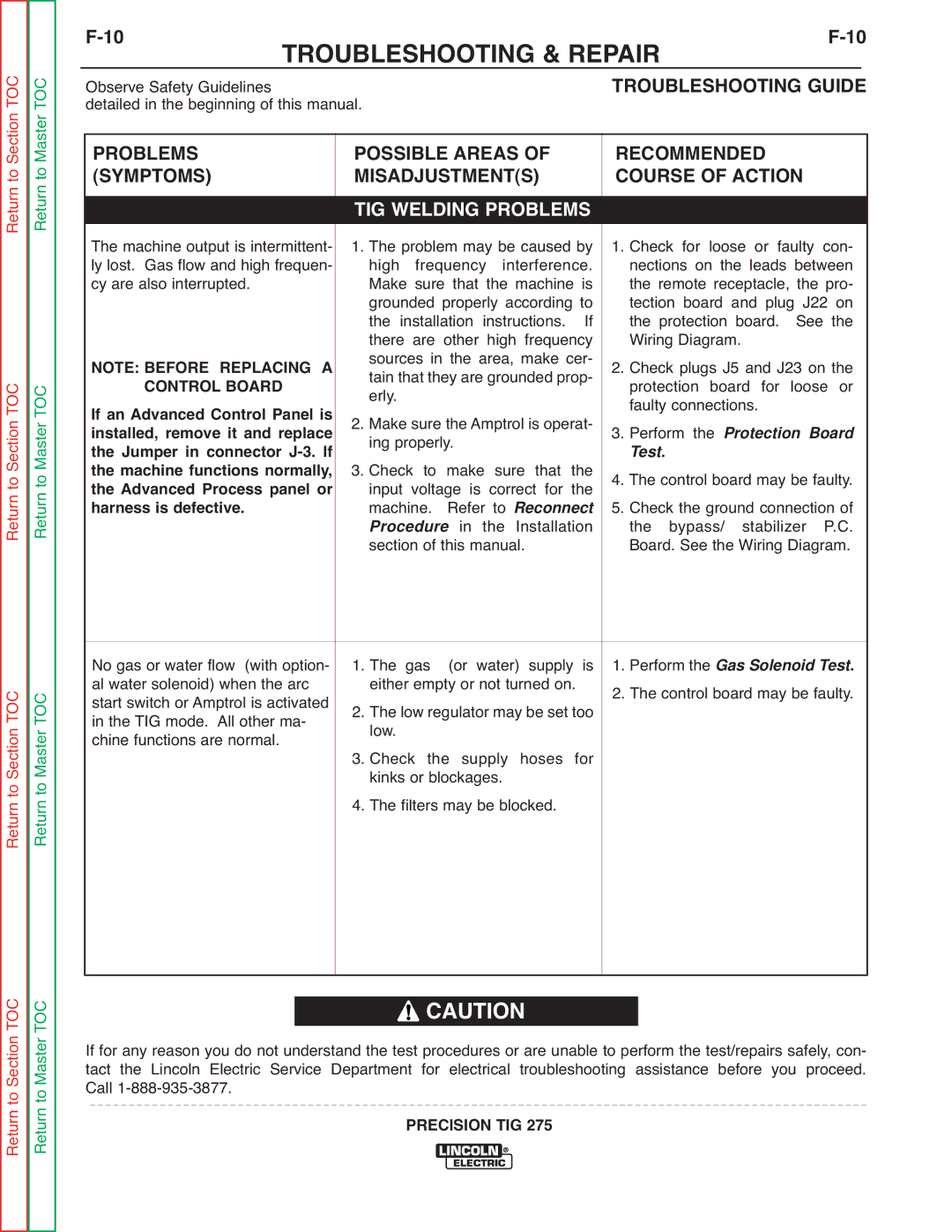

| TROUBLESHOOTING & REPAIR | |||||

| Observe Safety Guidelines |

|

| TROUBLESHOOTING GUIDE | ||

| detailed in the beginning of this manual. |

|

|

| ||

| PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

| |

| (SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| |

|

|

| TIG WELDING PROBLEMS |

|

|

|

| The machine output is intermittent- | 1. The problem may be caused by | 1. | Check for loose or faulty con- | ||

| ly lost. Gas flow and high frequen- | high frequency interference. |

| nections on the leads between | ||

| cy are also interrupted. |

| Make sure that the machine is |

| the remote receptacle, the pro- | |

|

|

| grounded properly according to |

| tection board and plug J22 on | |

|

|

| the installation instructions. If |

| the protection board. See the | |

| NOTE: BEFORE REPLACING A | there are other high frequency | 2. | Wiring Diagram. |

| |

| sources in the area, make cer- | Check plugs J5 and J23 on the | ||||

| CONTROL BOARD | tain that they are grounded prop- |

| protection board for loose or | ||

| If an Advanced Control Panel is | erly. | 3. | faulty connections. |

| |

| installed, remove it and replace | 2. Make sure the Amptrol is operat- | Perform the Protection Board | |||

| the Jumper in connector | ing properly. |

| est. |

| |

| the machine functions normally, | 3. Check to make sure that the | 4. The control board may be faulty. | |||

| the Advanced Process panel or | input voltage is correct for the | ||||

| harness is defective. |

| machine. Refer to Reconnect | 5. Check the ground connection of | ||

|

|

| Procedure in the Installation |

| the bypass/ stabilizer | P.C. |

|

|

| section of this manual. |

| Board. See the Wiring Diagram. | |

Return to Section TOC Return to Master TOC

No gas or water flow (with option- al water solenoid) when the arc start switch or Amptrol is activated in the TIG mode. All other ma- chine functions are normal.

1.The gas (or water) supply is either empty or not turned on.

2.The low regulator may be set too low.

3.Check the supply hoses for kinks or blockages.

4.The filters may be blocked.

1.Perform the Gas Solenoid Test.

2.The control board may be faulty

Return to Section TOC Return to Master TOC

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call