Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

Return to Section TOC Return to Master TOC

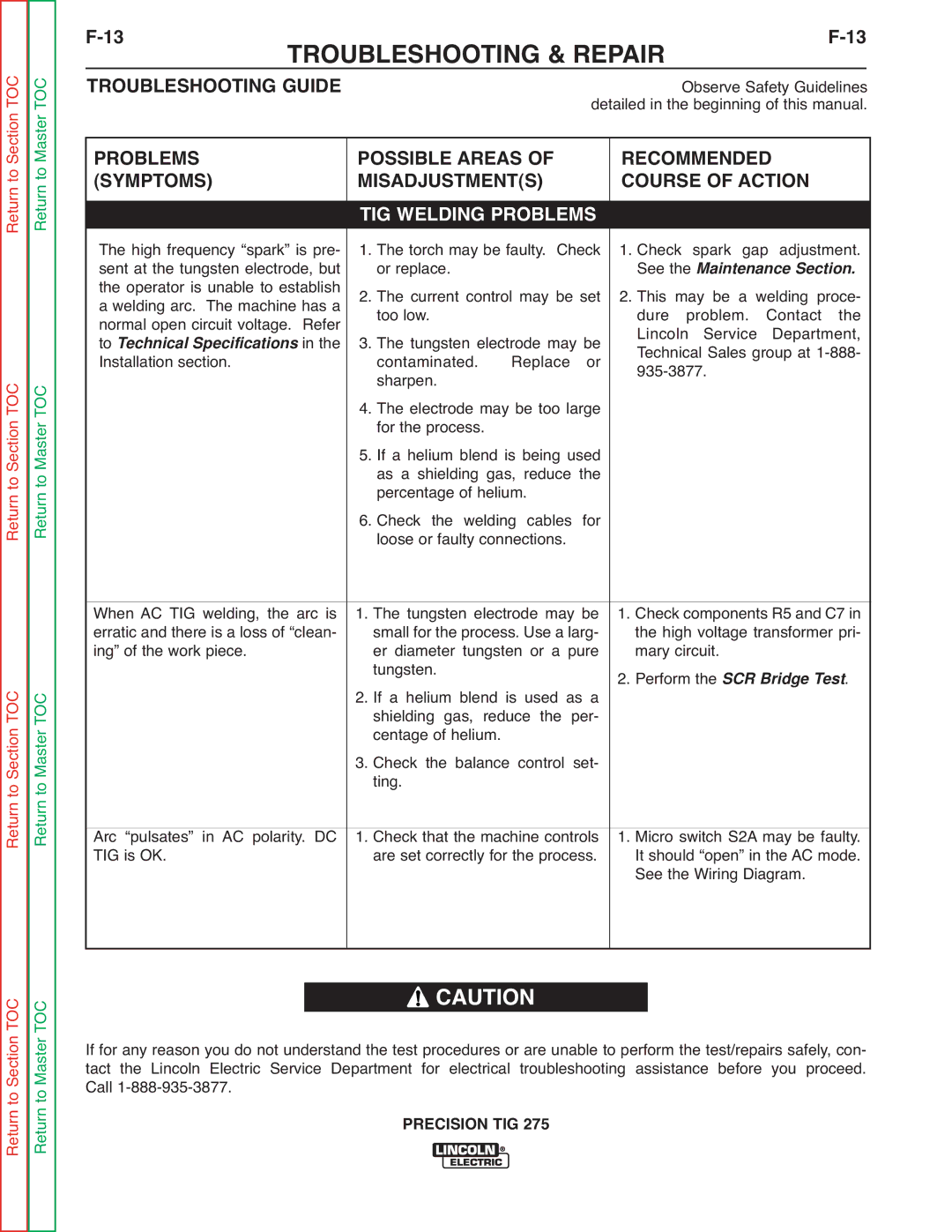

TROUBLESHOOTING & REPAIR |

|

| |||||

TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines | ||||

|

| detailed in the beginning of this manual. | |||||

PROBLEMS |

| POSSIBLE AREAS OF | RECOMMENDED |

|

| ||

|

|

| |||||

(SYMPTOMS) |

| MISADJUSTMENT(S) | COURSE OF ACTION |

| |||

|

| TIG WELDING PROBLEMS |

|

|

|

|

|

The high frequency “spark” is pre- | 1. The torch may be faulty. Check | 1. Check | spark gap | adjustment. | |||

sent at the tungsten electrode, but | or replace. | See the Maintenance Secti | n. | ||||

the operator is unable to establish | 2. The current control may be set | 2. This may be a welding proce- | |||||

a welding arc. The machine has a | |||||||

normal open circuit voltage. Refer | too low. | dure | problem. Contact | the | |||

to Technical Specifications in the | 3. The tungsten electrode may be | Lincoln Service | Department, | ||||

Installation section. |

| contaminated. Replace or | Technical Sales group at | ||||

|

| sharpen. |

|

|

| ||

|

| 4. The electrode may be too large |

|

|

|

|

|

|

| for the process. |

|

|

|

|

|

|

| 5. If a helium blend is being used |

|

|

|

|

|

|

| as a shielding gas, reduce the |

|

|

|

|

|

|

| percentage of helium. |

|

|

|

|

|

|

| 6. Check the welding cables for |

|

|

|

|

|

|

| loose or faulty connections. |

|

|

|

|

|

When AC TIG welding, the arc is | 1. The tungsten electrode may be | 1. Check components R5 and C7 in | |||||

erratic and there is a loss of “clean- | small for the process. Use a larg- | the high voltage transformer pri- | |||||

ing” of the work piece. |

| er diameter tungsten or a pure | mary circuit. |

|

|

| |

|

| tungsten. | 2. Perform the | SCR Bridge Test | |||

|

| 2. If a helium blend is used as a |

|

| . | ||

|

| shielding gas, reduce the per- |

|

|

|

|

|

|

| centage of helium. |

|

|

|

|

|

|

| 3. Check the balance control set- |

|

|

|

|

|

|

| ting. |

|

|

|

|

|

Arc “pulsates” in AC polarity. DC | 1. Check that the machine controls | 1. Micro switch S2A may be faulty. | |||||

TIG is OK. |

| are set correctly for the process. | It should “open” in the AC mode. | ||||

|

|

| See the Wiring Diagram. |

| |||

|

|

|

|

|

|

|

|

Return to Section TOC Return to Master TOC

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the test/repairs safely, con- tact the Lincoln Electric Service Department for electrical troubleshooting assistance before you proceed. Call