M R V C o m m u n i c a t i o n s , I n c . – I n s t a l l a t i o n M a n u a l

Fine Alignment Vertical Motion Screws – Two screws (‘C’). Used for fine rotation of the TereScope in the vertical plane.

Fine Alignment Horizontal Motion Screws – Two screws (‘B’). Used for fine rotation of the TereScope in the horizontal plane..

Note

#Two installers are required for fine alignment, one at each TereScope site.

#The installers should each have a

The fine alignment procedure is as follows:

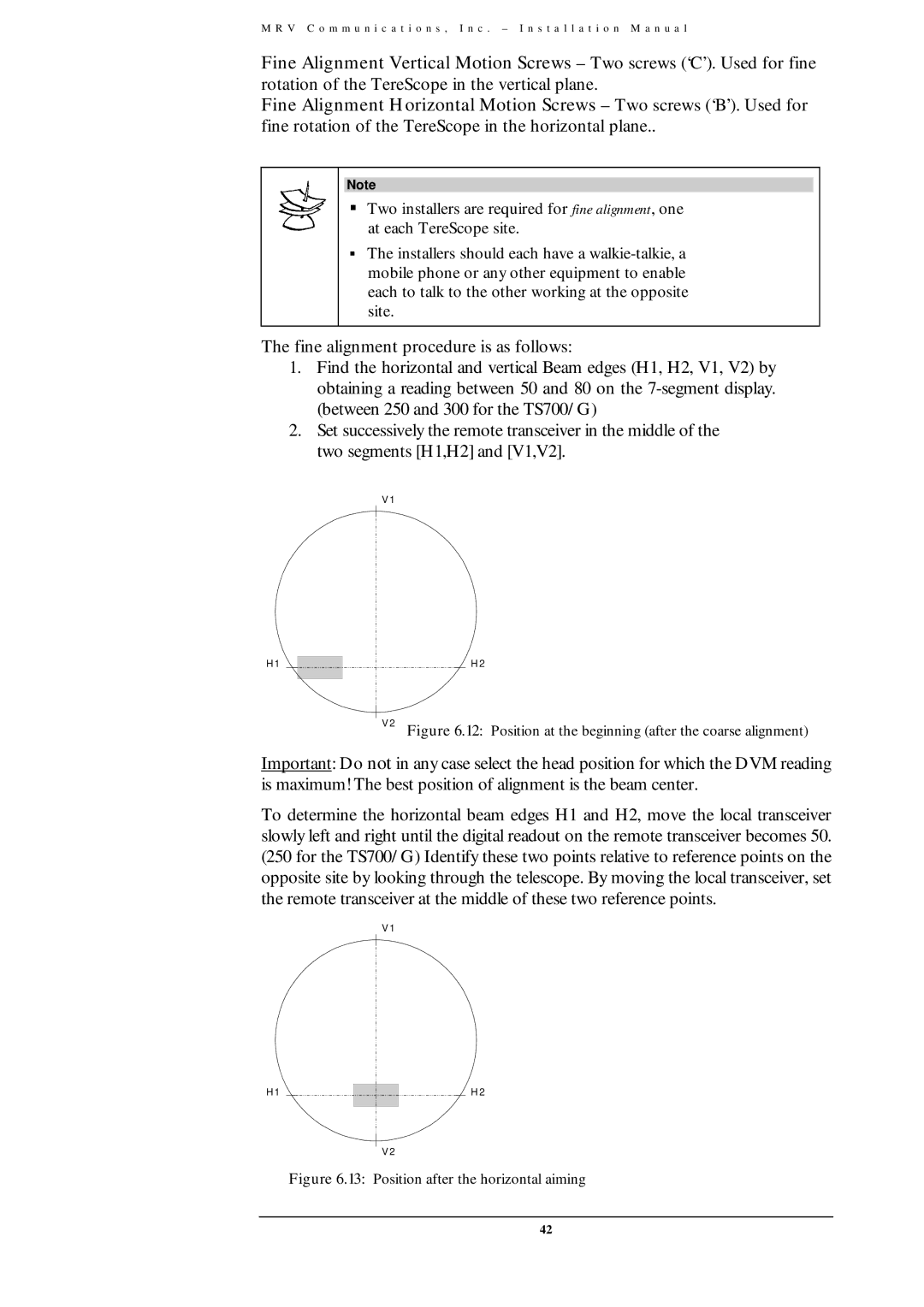

1.Find the horizontal and vertical Beam edges (H1, H2, V1, V2) by obtaining a reading between 50 and 80 on the

2.Set successively the remote transceiver in the middle of the two segments [H1,H2] and [V1,V2].

V1

H1

H2

V2 Figure 6.12: Position at the beginning (after the coarse alignment)

Important: Do not in any case select the head position for which the DVM reading is maximum! The best position of alignment is the beam center.

To determine the horizontal beam edges H1 and H2, move the local transceiver slowly left and right until the digital readout on the remote transceiver becomes 50. (250 for the TS700/G) Identify these two points relative to reference points on the opposite site by looking through the telescope. By moving the local transceiver, set the remote transceiver at the middle of these two reference points.

V1

H1

H2

V2

Figure 6.13: Position after the horizontal aiming

42