1.5.1.5 Adjusting the Roll Paper Near End Sensing Position

The paper near end detector detects when the paper is almost gone by measuring the diameter of the Roll paper.

If you want to change the amount of paper remaining when the printer stops printing, follow the steps below to adjust the paper near end detector.

Note: If the inner diameter of the Roll paper core is more than 26mm (1.02 inch), the Roll paper near end detector may not work properly.

1.Open the printer cover and remove the rewinder.

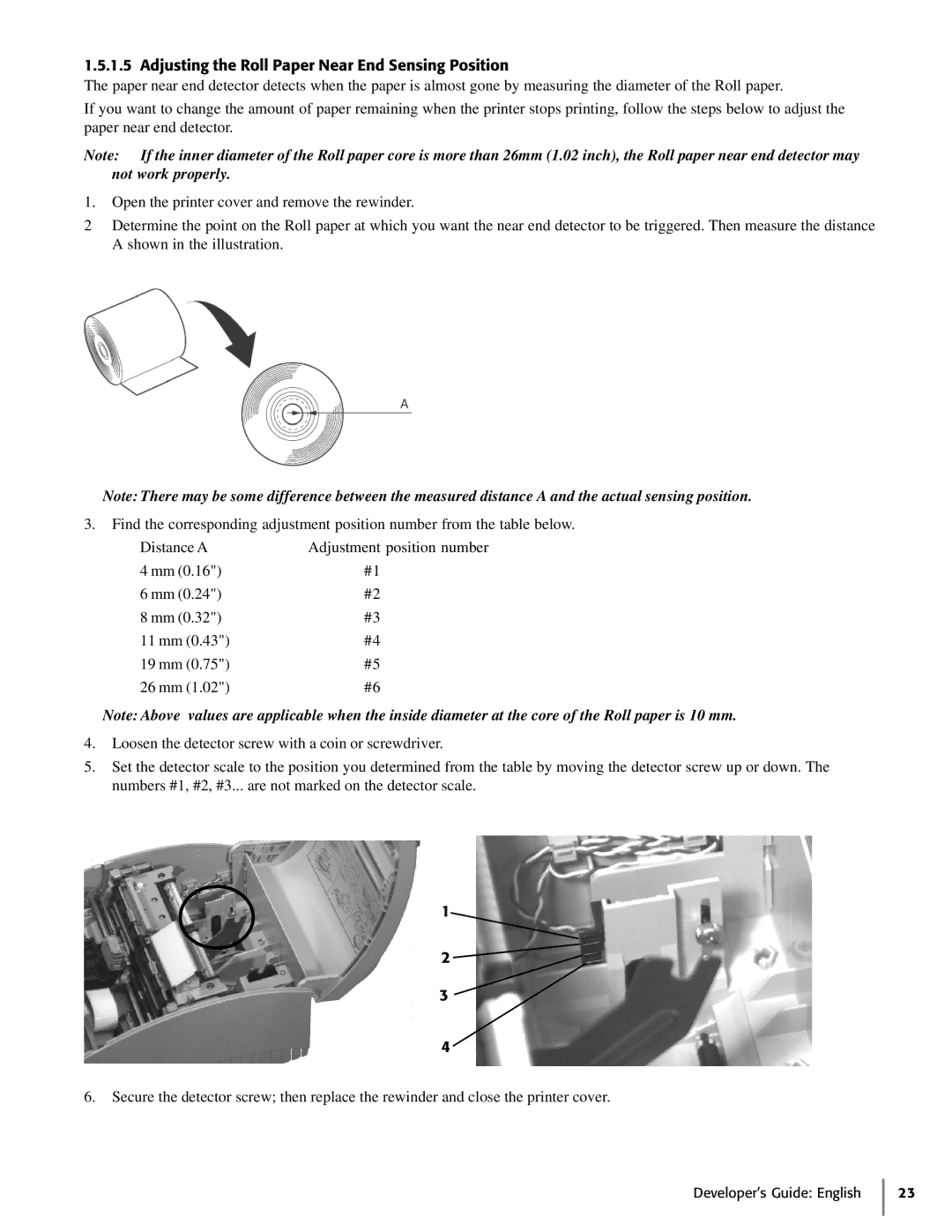

2Determine the point on the Roll paper at which you want the near end detector to be triggered. Then measure the distance A shown in the illustration.

Note: There may be some difference between the measured distance A and the actual sensing position.

3.Find the corresponding adjustment position number from the table below.

Distance A | Adjustment position number |

4 mm (0.16") | #1 |

6 mm (0.24") | #2 |

8 mm (0.32") | #3 |

11 mm (0.43") | #4 |

19 mm (0.75") | #5 |

26 mm (1.02") | #6 |

Note: Above values are applicable when the inside diameter at the core of the Roll paper is 10 mm.

4.Loosen the detector screw with a coin or screwdriver.

5.Set the detector scale to the position you determined from the table by moving the detector screw up or down. The numbers #1, #2, #3... are not marked on the detector scale.

1

2

3

4

6.Secure the detector screw; then replace the rewinder and close the printer cover.