5.7.5.1.2 Paper Quality

The paper in the following quality may be used.

Type

Paper Quality

High quality paper

1Paper smoothness must be 90 ~ 7 sec. for Beek and 75 ~ 300 sec. for Sheffield.

2If you use paper other than that specified, test it to verify that it prints without problems.

5.7.5.1.3 Paper Weight and Maximum Duplicating Quantity

The weight of paper usable for printing and max. duplicating quantity are shown in the table below.

Type

Single- part paper

Stub

Paper Quality

High quality paper

High quality paper

Pressure- sensitive paper,

Weight

52~105 g/m2 (14~28 lb) ← Slip 65~81 g/m2 (17~21 lb) ← Validation

65~81 g/m2 (17~21 lb)

34~40 g/m2 (9~11 lb)

Max. | Total Paper |

Copies | Thickness |

- | - |

|

|

- | - |

|

|

5 copies | 0.30mm or |

(original + | less |

4 copies) |

|

|

|

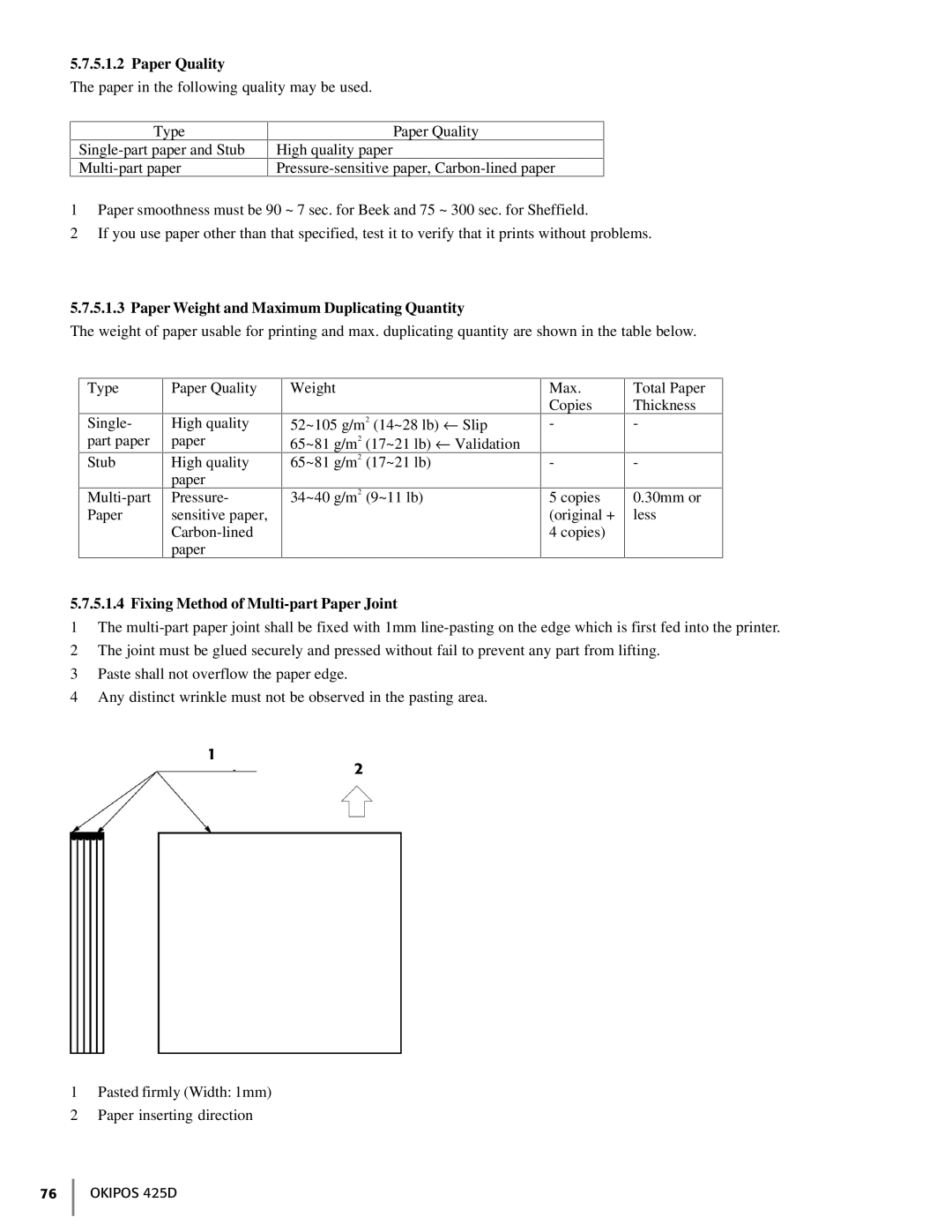

5.7.5.1.4 Fixing Method of Multi-part Paper Joint

1The

2The joint must be glued securely and pressed without fail to prevent any part from lifting.

3Paste shall not overflow the paper edge.

4Any distinct wrinkle must not be observed in the pasting area.

1

2

1Pasted firmly (Width: 1mm)

2Paper inserting direction