TMS320 SECOND-GENERATION

DEVICES

SPRS010B Ð MAY 1987 Ð REVISED NOVEMBER 1990

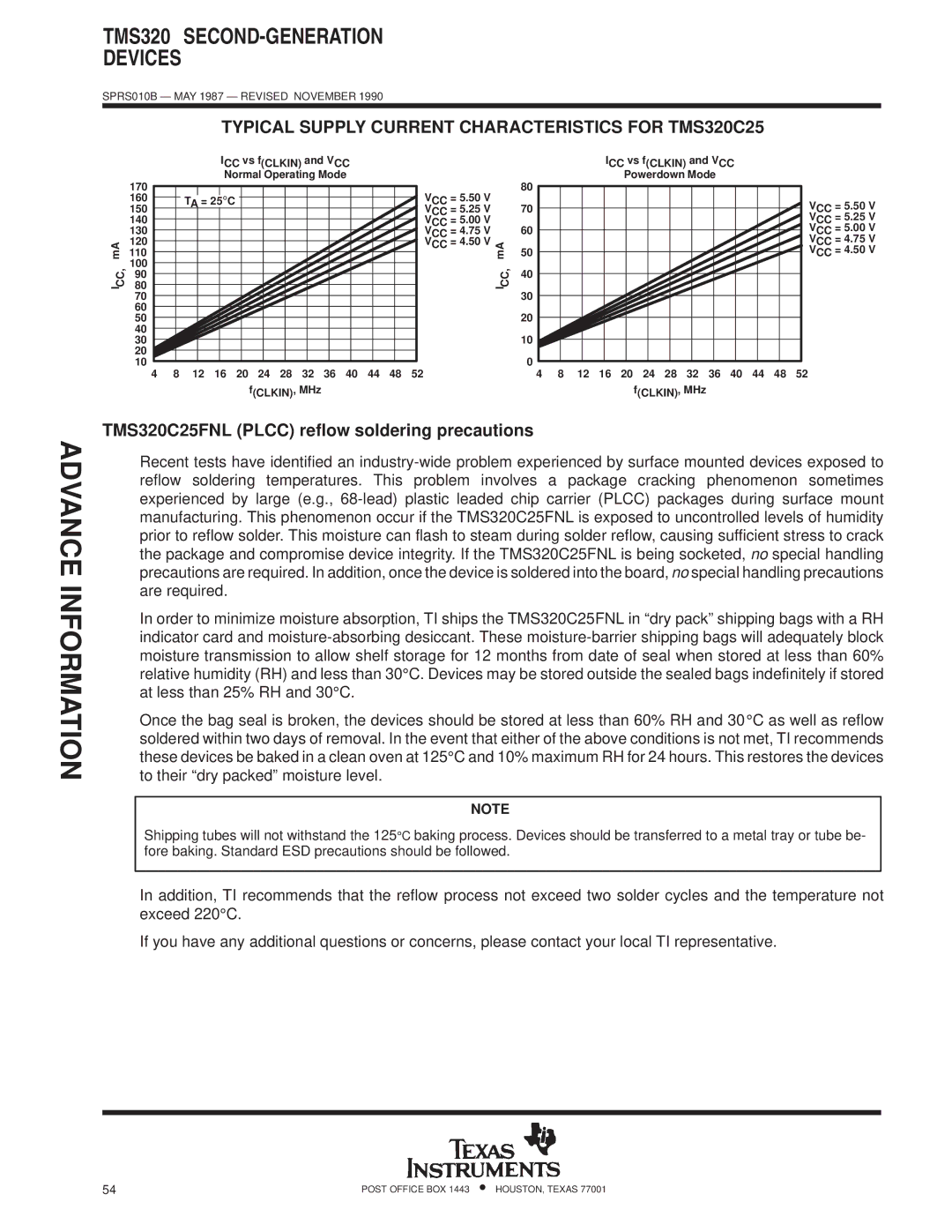

TYPICAL SUPPLY CURRENT CHARACTERISTICS FOR TMS320C25

ICC vs f(CLKIN) and VCC | ICC vs f(CLKIN) and VCC |

Normal Operating Mode | Powerdown Mode |

ICC, mA

170

160TA = 25°C

140

130

120

110

100

90

80

70

60

50

40

30

20

10

48 12 16 20 24 28 32 36 40 44 48 52 f(CLKIN), MHz

VCC = 5.50 V VCC = 5.25 V VCC = 5.00 V VCC = 4.75 V VCC = 4.50 V

ICC, mA

80

70

60

50

40

30

20

10

0

48 12 16 20 24 28 32 36 40 44 48 52 f(CLKIN), MHz

VCC = 5.50 V VCC = 5.25 V VCC = 5.00 V VCC = 4.75 V VCC = 4.50 V

ADVANCE INFORMATION

TMS320C25FNL (PLCC) reflow soldering precautions

Recent tests have identified an

In order to minimize moisture absorption, TI ships the TMS320C25FNL in ªdry packº shipping bags with a RH indicator card and

Once the bag seal is broken, the devices should be stored at less than 60% RH and 30°C as well as reflow soldered within two days of removal. In the event that either of the above conditions is not met, TI recommends these devices be baked in a clean oven at 125°C and 10% maximum RH for 24 hours. This restores the devices to their ªdry packedº moisture level.

NOTE

Shipping tubes will not withstand the 125°C baking process. Devices should be transferred to a metal tray or tube be- fore baking. Standard ESD precautions should be followed.

In addition, TI recommends that the reflow process not exceed two solder cycles and the temperature not exceed 220°C.

If you have any additional questions or concerns, please contact your local TI representative.

54 | POST OFFICE BOX 1443 • HOUSTON, TEXAS 77001 |