7.5.2 PAPER PRE-STACKING

[A]

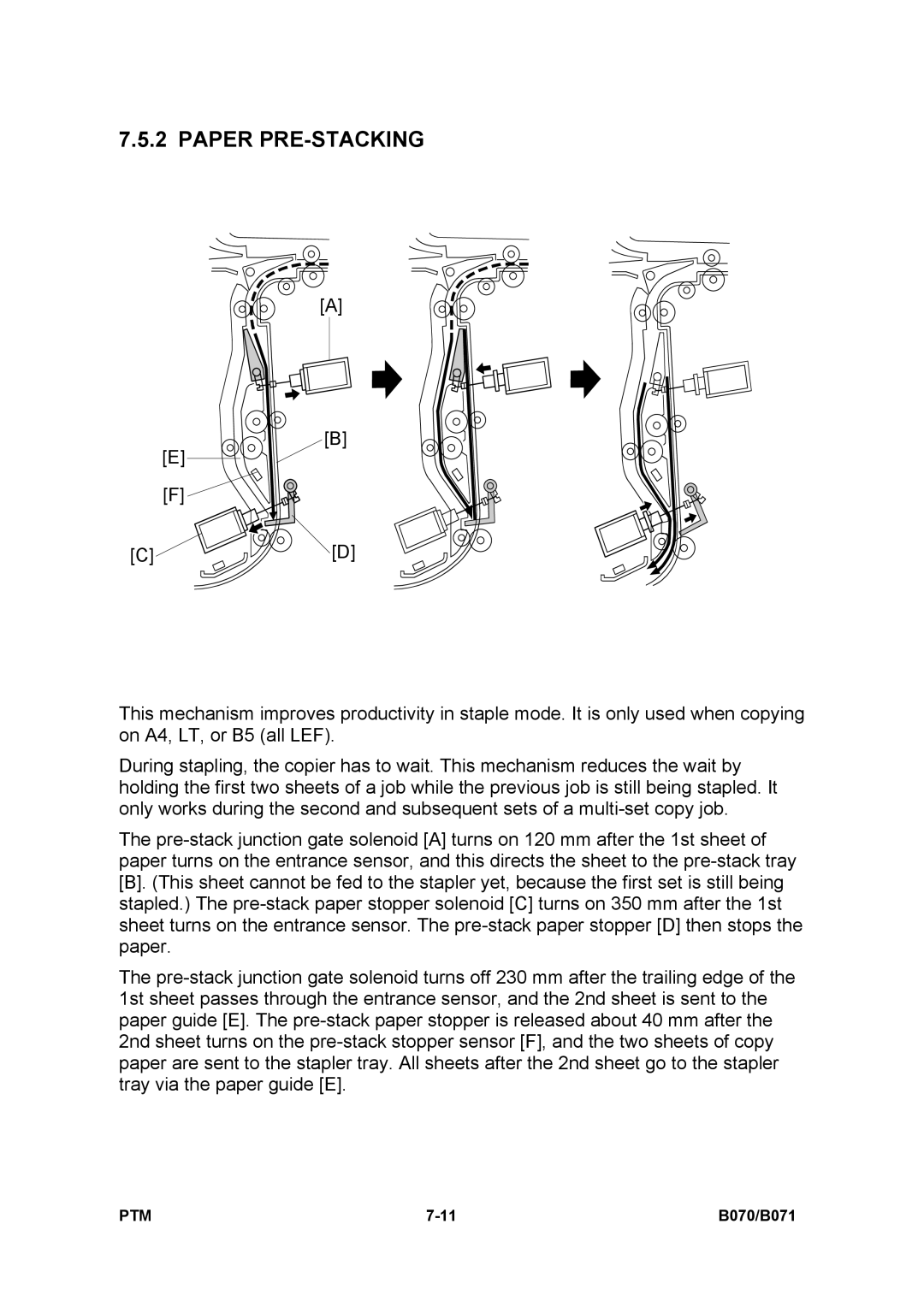

This mechanism improves productivity in staple mode. It is only used when copying on A4, LT, or B5 (all LEF).

During stapling, the copier has to wait. This mechanism reduces the wait by holding the first two sheets of a job while the previous job is still being stapled. It only works during the second and subsequent sets of a multi-set copy job.

The pre-stack junction gate solenoid [A] turns on 120 mm after the 1st sheet of paper turns on the entrance sensor, and this directs the sheet to the pre-stack tray

[B].(This sheet cannot be fed to the stapler yet, because the first set is still being stapled.) The pre-stack paper stopper solenoid [C] turns on 350 mm after the 1st sheet turns on the entrance sensor. The pre-stack paper stopper [D] then stops the paper.

The pre-stack junction gate solenoid turns off 230 mm after the trailing edge of the 1st sheet passes through the entrance sensor, and the 2nd sheet is sent to the paper guide [E]. The pre-stack paper stopper is released about 40 mm after the 2nd sheet turns on the pre-stack stopper sensor [F], and the two sheets of copy paper are sent to the stapler tray. All sheets after the 2nd sheet go to the stapler tray via the paper guide [E].