2.6 DEVELOPMENT

2.6.1 OVERVIEW

6 7 8

3

9

10

13 | 5 |

1

2

4

12

11

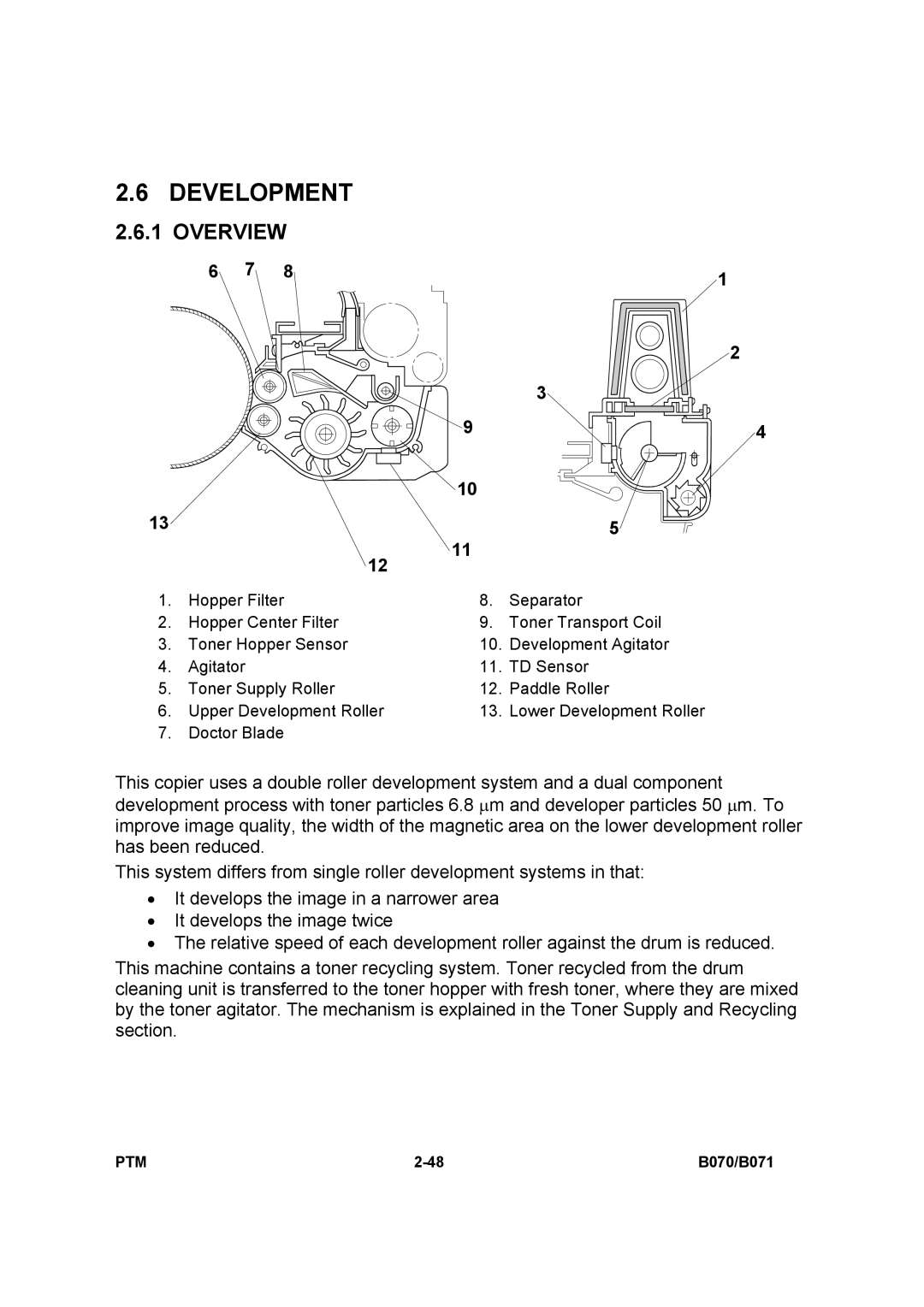

1. | Hopper Filter | 8. | Separator |

2. | Hopper Center Filter | 9. | Toner Transport Coil |

3. | Toner Hopper Sensor | 10. | Development Agitator |

4. | Agitator | 11. | TD Sensor |

5. | Toner Supply Roller | 12. | Paddle Roller |

6. | Upper Development Roller | 13. | Lower Development Roller |

7. | Doctor Blade |

|

|

This copier uses a double roller development system and a dual component development process with toner particles 6.8 ∝m and developer particles 50 ∝m. To improve image quality, the width of the magnetic area on the lower development roller has been reduced.

This system differs from single roller development systems in that:

•It develops the image in a narrower area

•It develops the image twice

•The relative speed of each development roller against the drum is reduced.

This machine contains a toner recycling system. Toner recycled from the drum cleaning unit is transferred to the toner hopper with fresh toner, where they are mixed by the toner agitator. The mechanism is explained in the Toner Supply and Recycling section.

PTM | B070/B071 |