2.10 FUSING

2.10.1 OVERVIEW

[E] [D]

[A]

[G]

[F]

[H]

[C] |

[B] |

[I]

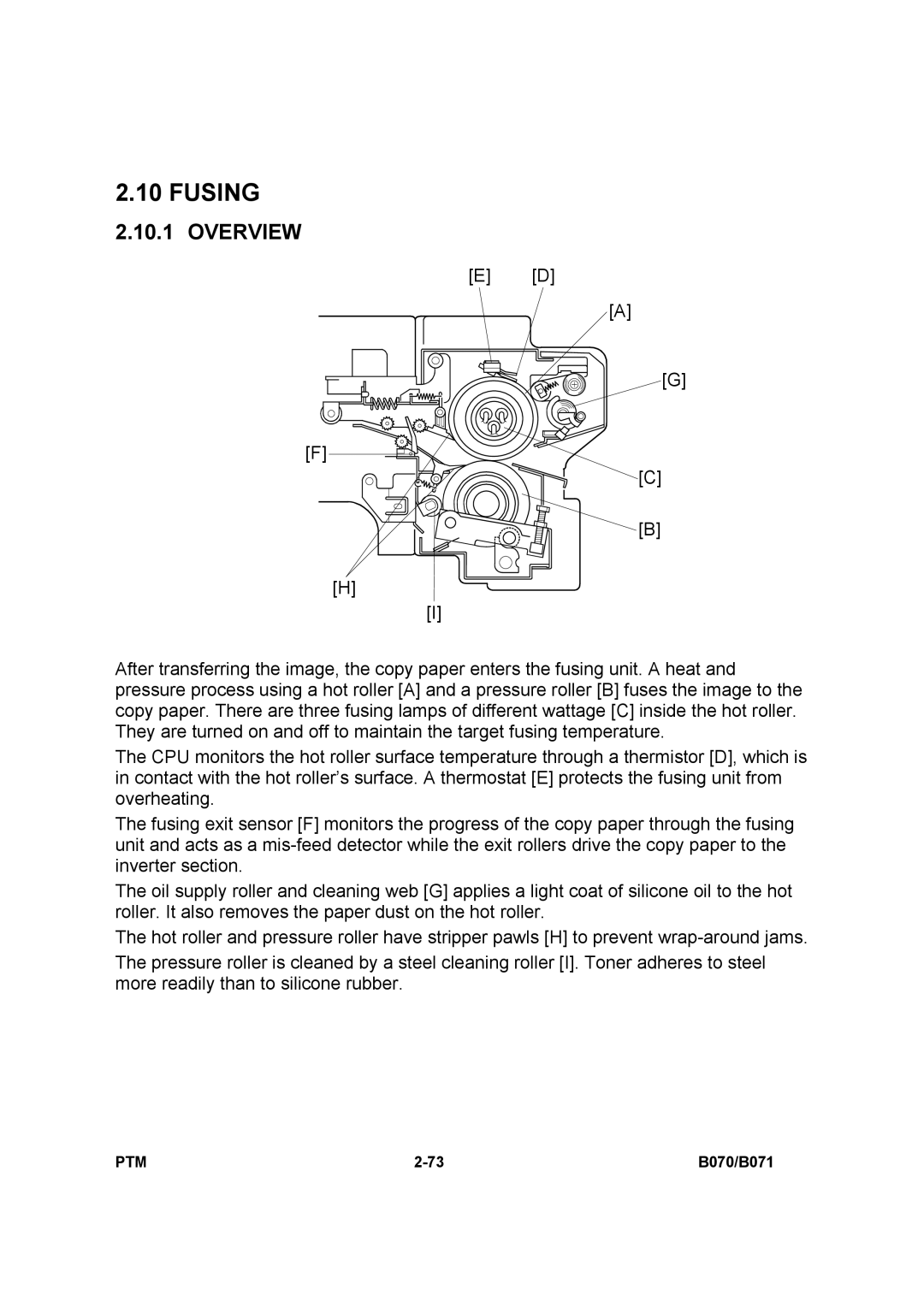

After transferring the image, the copy paper enters the fusing unit. A heat and pressure process using a hot roller [A] and a pressure roller [B] fuses the image to the copy paper. There are three fusing lamps of different wattage [C] inside the hot roller. They are turned on and off to maintain the target fusing temperature.

The CPU monitors the hot roller surface temperature through a thermistor [D], which is in contact with the hot roller’s surface. A thermostat [E] protects the fusing unit from overheating.

The fusing exit sensor [F] monitors the progress of the copy paper through the fusing unit and acts as a

The oil supply roller and cleaning web [G] applies a light coat of silicone oil to the hot roller. It also removes the paper dust on the hot roller.

The hot roller and pressure roller have stripper pawls [H] to prevent

The pressure roller is cleaned by a steel cleaning roller [I]. Toner adheres to steel more readily than to silicone rubber.

PTM | B070/B071 |