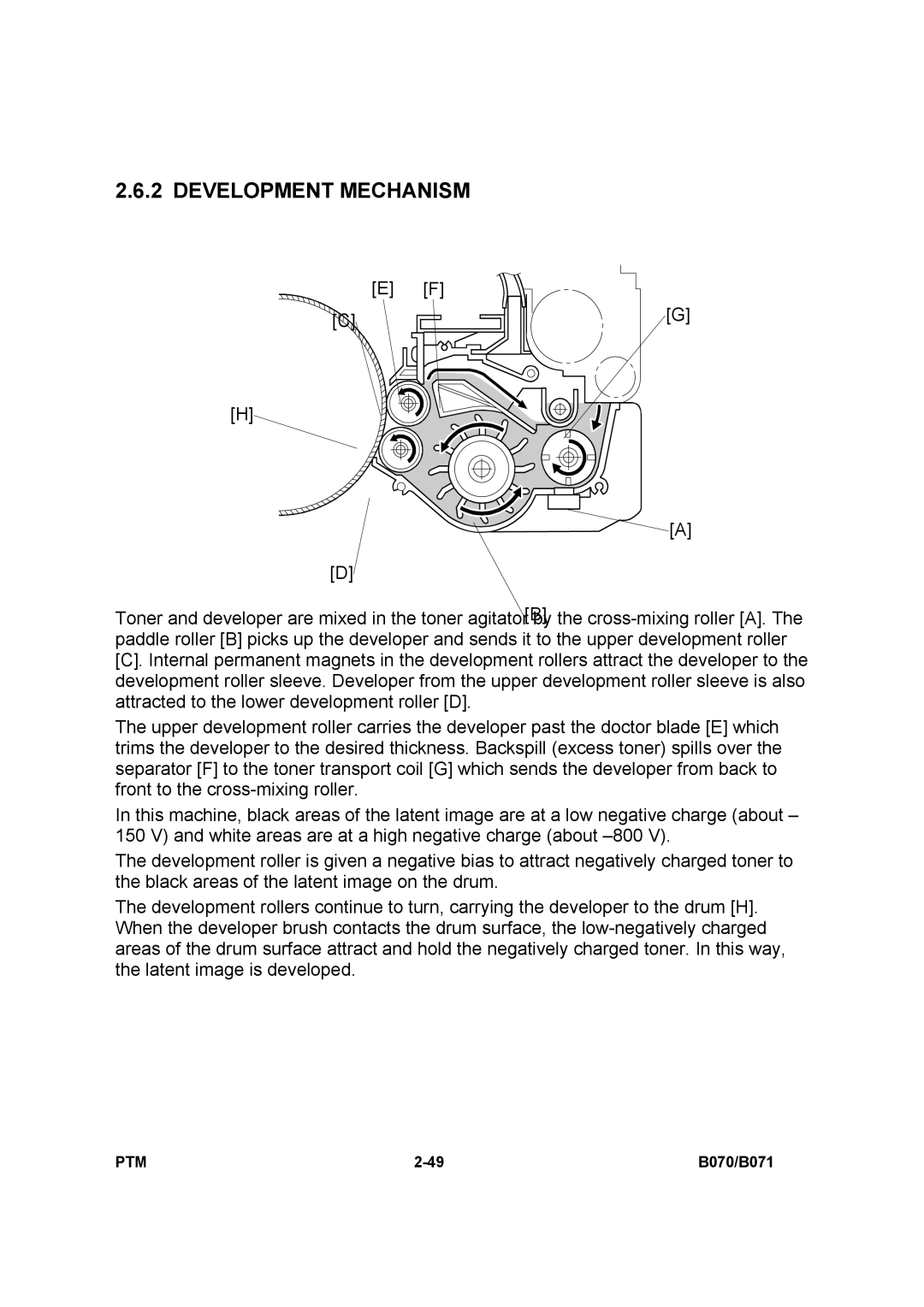

2.6.2 DEVELOPMENT MECHANISM

[E] | [F] |

[C] |

|

[H]

[G]

![]()

![]()

![]() [A]

[A]

[D]

[B]

Toner and developer are mixed in the toner agitator by the

[C].Internal permanent magnets in the development rollers attract the developer to the development roller sleeve. Developer from the upper development roller sleeve is also attracted to the lower development roller [D].

The upper development roller carries the developer past the doctor blade [E] which trims the developer to the desired thickness. Backspill (excess toner) spills over the separator [F] to the toner transport coil [G] which sends the developer from back to front to the

In this machine, black areas of the latent image are at a low negative charge (about – 150 V) and white areas are at a high negative charge (about

The development roller is given a negative bias to attract negatively charged toner to the black areas of the latent image on the drum.

The development rollers continue to turn, carrying the developer to the drum [H]. When the developer brush contacts the drum surface, the

PTM | B070/B071 |