MJ-1103/1104

Trademarks

Page

Page

Contents

Saddle Stitch Finisher stapler related error MJ-1104

Paper jam in movable tray section

SPECIFICATIONS, Accessory and Consumables

Specifications

Finisher section Common for MJ-1103/1104

Stacking Type Facedown Stacking Height with Stationary Tray

Paper Size

Height

Paper Size

A4, B5, LT, 8.5SQ, 16K A3, A4-R, B4, FOLIO, LD, LG, LT-R

Saddle stitch section MJ-1104

Thick paper cover included

64 80g/m 2 Paper 81 90g/m 2 Paper 91 105g/m 2 Paper

91 105g/m2 Paper

Consumables

Accessory

MJ-1103 MJ-1104

General Description

Main Components

Sectional View

Units

Paper exit guide clutch

Finisher section B-1 Front side view

Gate solenoid

Rear side view

Saddle section C-1 Front side view

M16 M17

M14

Transport roller

Paper holding damper

Electric Parts Layout

SOL2 M10 CLT2 M12 M2

M13

S19

S20

Symbol Name Function Remarks

Symbols and Functions of Various Components

Motors Saddle section MJ-1104

Solenoids Finisher section Common for MJ-1103/1104

Electromagnetic spring clutches Saddle section MJ-1104

Solenoids Saddle section MJ-1104

Stapler home position sensor

P11-I20 7 Fig For the stapling operation

PC board Finisher section Common for MJ-1103/1104

Sensors and switches Saddle section MJ-1104

PC board Saddle section MJ-1104

Diagram of Signal Blocks

Finisher section

Saddle section

ROM

Description of Interface Signals

Equipment connection switch Connected 24V power supplied

Sent data transmitted from the Equipment to the Finisher

Equipment TxD Converter RxD Finisher PC board

General Description

Description of Operations

Basic Operations

Junction box Side alignment Unit

Fold unit Stacker EFS unit Saddle tray

Junction Box

Junction box paper detection sensor

Finisher paper feeding section

Simple Stack Mode

Gate flap Entrance roller Gate solenoid

Paper exit to the stationary tray

Stationary Tray roller Entrance sensor Exit motor

Paper exit to the movable tray

Operation of Movable Tray

Movable tray position

Position-C sensor

Job offset stack mode / Staple stack mode

Paper transport section

Mulch-active drop mechanism section

Paper pusher home position sensor

Paper pushing arm motor

Paper pushing plate Catching pad

Description of Operations

Stapler interference switch

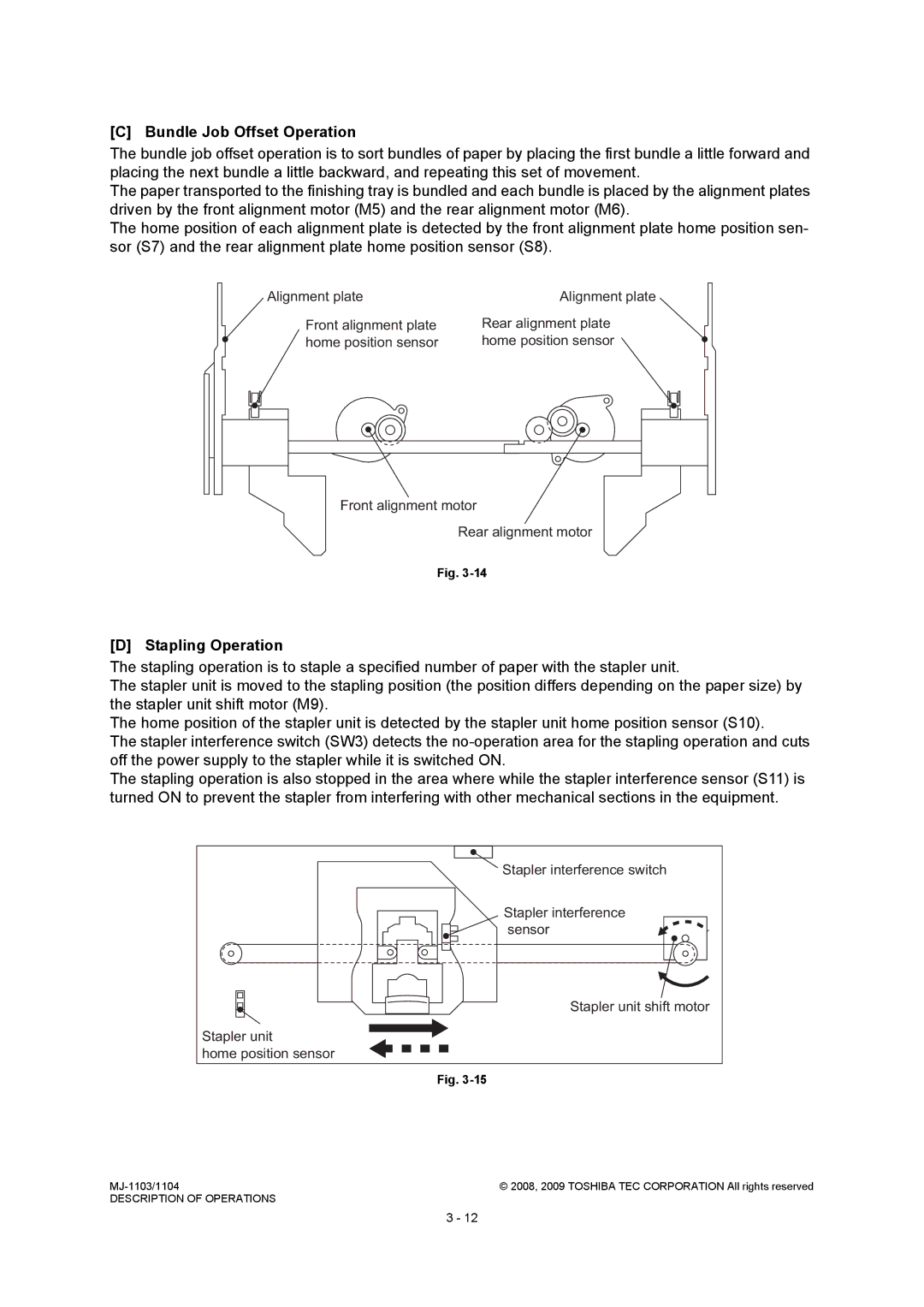

Bundle Job Offset Operation

Stapling Operation

Stapler interference

Stack transport roller-2 Paper exit belt

Paper exiting operation

Clutch

Operation in the saddle stitch section

Saddle stitch feeding section

Stack transport

Side alignment

Paper holding

Stapling

Folding

Folding motor encoder sensor

Exit transport sensor Folding roller

Additional folding / exiting

Flow Chart

Simple stack mode

Exit motor on

Transport sensor ON?

Bundle job offset mode/ stapling stack mode

Center-binding mode

Entrance motor on

Feeding Sensor ON?

Saddle transport motor on

Description Of Circuit

Finishier section

Buffer roller drive circuit

Motor rotation Remarks

Paper pushing arm motor drive circuit

By the paper pushing plate

Guide is closed

Buffer tray guide motor drive circuit

Guide is opened

Front / rear alignment motor drive circuit

Front alignment plate is closed

Front alignment plate is opened

Rear alignment plate is closed

Stack transport motor drive circuit

Entrance motor drive circuit

Paper is pulled

Paper is transported to the stationary tray

Exit motor drive circuit

Or buffer tray

Stapler unit is shifted to the front side

Stapler unit shift motor drive circuit

Stapler unit is shifted to the rear side

Paper is transported to the finishing posi

Transport motor drive circuit

Tion

Paddle motor drive circuit

Paper is pulled into the finishing position

Then pushed off

Eliminates backlash

Movable tray shift motor drive circuit

Movable tray unit is shifted to the lower side

Movable tray unit is shifted to the upper side

Stop

Reset circuit

Recovery operation

Stapler motor drive circuit

IC22

Saddle section

Stacker motor drive circuit

Stacker is moved to the stapling

Position

Side alignment motor drive circuit

Paper is aligned to fix their side

Ways deviation with a jog moved

Open the jog

Front / Rear saddle stapler motor drive circuit

Only when the stapler operates abnormally

Initial operation

Saddle transport motor drive circuit

Paper is transported

At a transport speed lower than 200 mm

At a transport speed 400 mm/s or higher

Folding motor drive circuit

Operates the folding

Paper is exited to the saddle tray

Stop Not used

Additional folding motor drive circuit

Operates the additional folding

Covers

Stationary tray

Movable tray

Saddle tray

Movable tray

Leveling arm

Connector

Control panel unit

Remove 1 screw on the upper side of the front rail cover

Saddle tray

Front cover

Front lower cover MJ-1104

Front upper cover MJ-1104

Front lower cover

Access cover

Handle cover / Cover lock bracket

Rear cover

Finisher cable

Right upper cover

Saddle access cover

Relay guide / Feeding discharge brush / Right cover

Left upper cover

Remove 3 screws, and then take off the left upper cover

Clamp

Hook

Front rail cover / Rear rail cover

Take off the movable tray. P.4-2 B Movable tray

Front rail

Cover

Connector

Grate-shaped guide

Relay

Shutter Hook

Left lower cover Left lower cover MJ-1103

Grate-shaped

Guide

Clamp Harness

Left lower cover MJ-1104

Front foot cover / Rear foot cover

Cover

Front foot cover

Units Finisher section

Junction box unit

Clamp

If board

Disconnect the connector of the front cover switch

Belt

Rear rail guide

Buffer unit

Entrance motor

Buffer unit

Remove 4 screws, and then take off the buffer unit

Paper pusher plate Buffer guide

Connector Buffer tray guide motor

Disconnect the connector of the buffer tray guide motor

Buffer unit-1

Relay Connector Cramp

Take off the belt of the buffer roller drive motor

Plate

Finishing tray unit

Buffer unit-1

Bushing

Clip

Belt

Spring

Belt Pin Bushing Clips Transport roller pulley-3

Stapler

Flexible cable

Protrusion

Staple carrier

Movable tray shift motor unit

Sensor rail

Sensor rail

Measure

Bushing

Bracket

Shift motor unit

Units Saddle section MJ-1104

Saddle unit

SDL board

Table beneath

Frame

Shaft

Support

Switchback unit

Rear bracket Support Bracket Front bracket

Paper holding unit

Paper holding unit

Side alignment unit

Saddle stapler unit

Pler frame assembly

Install the jig on the hole of the lower sta Pler frame

Remove 4 screws and take off the upper sta

Upper stapler

Fold plate

Front saddle stapler

Mylar

Binding wire

Folding drive unit

Remove one clip and then remove the bush Ing

Bushing Clip

Remove one clip and then remove the pulley and pin

Pin Pulley

Spring Folding drive unit

Scale Mark Gear bracket

Wire

Relay connector

EFS unit

Clanp

Rear bracket

Access lever

EFS jam

Stacker unit

Stacker unit

Rollers Finisher section

Feeding roller

Board

Front bracket Junction box upper Transport guide

Remove one screw, and then sensor bracket of feeding sensor

Jam access lever

Sensor

Junction roller

Knob

Pulley

Pin Gear

Remove 3 screws, and then take off the transport guide

Clip

Junction roller

Screw

Arm

Take off the arm by pulling it out upward

Catching pad Arm Arm linkage portion

Rear alignment plate

Front pull-in guide

Jig Rear pull-in guide

Rear finishing tray cover

Paddle shaft

Rear Pull-in guide Front

Front transport roller / Rear transport roller

Rear transport roller

Front transport roller

Entrance roller

Pulley Bushing Rear transport roller

Remove 1 E-ring, and then slide 1 bushing

Then take off the entrance roller

Remove 1 E-ring. Then remove 1 pulley

Bushing and 1 pin from the entrance roller

Stack transport roller-1

Rear finishing tray cover

Stack transport roller-2

Buffer roller

Buffer tray guide motor

Buffer roller drive motor

Remove 2 screws, and then take off the rear side frame

Rear side

Buffer roller

Front buffer roller guide

Take off the lift guide from the buffer roller

Rear buffer roller guide

Spacer

Lift guide

When installing the front and rear stationary

Tions where the gap between the trailing

Upper exit roller / Upper exit roller guide

Tray transport guides, fix them at the posi

Remove 4 screws of the upper exit roller guide

Remove 5 E-rings, 1 gear, 1 pin, 1 actuator and 2 bushings

Upper exit roller guide

Upper exit roller

Switchback transport roller

Feed knob Bushing Assembly Belt

Switchback

Rollers Saddle section MJ-1104

Assisting roller

Belt

Ejecting roller

Clip Bushing

Remove the 2 springs

Spring

Bushing Pin

Ejecting roller Bushing Arm

Remove 2 E-rings and take off the 2 bearing

Upper folding roller / Lower folding roller

Bearing

Remove 1 E-rings and take off the gear and pin

Jam release lever Upper folding roller

Pin

Bearing

Exit roller

Jam release lever Lower folding roller

Lower transport guide

Clip Bushing Exit roller

Motor Finisher section

Entrance motor M1

Remove 2 screws, and then remove the motor damper

Buffer tray guide motor M2

Paddle motor M3

Buffer roller drive motorM4

Front alignment motor Clamp Relay connector

Front alignment motor M5

Rear alignment motor M6

Transport motor M7

Stack transport motor M8

Shaft Gear Pin

Remove 2 screws and then take off the bracket

Stapler unit shift motor M9

Relay Connector Clamp

Paper pusher arm motorM10

Shift motor

Take off the stationary tray. P.4-1 a Stationary tray

Exit motor M11

Assembly

Exit motor

Movable tray shift motor

Sensor rail

Movable tray shift motor

Motor Saddle section MJ-1104

Stacker motor M14

Stacker

Motor bracket Gear

Side alignment motor M15

Upper safety cover

Stacker Motor Clamp

Remove 2 screws, and then take off the motor bracket

Saddle transport motor M16

Motor bracket

Take off the belt of folding motor

Folding motor M17

Remove 2 screws and take off the folding motor

Clamp Binding wire

Additional folding motor M20

Shutter clutch CLT1

Solenoid

Paper exit guide clutch CLT2

Folding blade clutch CLT3

Protection

Catching solenoid SOL1

Paper holding clutch CLT4 MJ-1104

Take off the junction box unit P.4-13 a Junction box unit

Remove 2 screws, and then take off the catching solenoid

Buffer roller lift solenoid SOL2 / Patting solenoid SOL3

Solenoid sensor unit

Damper

Gate solenoid SOL4

Buffer roller lift solenoid Patting solenoid

Remove 3 screws, and then take off Remove the spring

Scale Bracket

Transport path switching solenoid SOL5 MJ-1104

Remove 2 screws, and then take off the gate solenoid

Bracket Gate flap

Shaft of the entrance roller

Belt

Binding wire

Arm Transport path switching solenoid Surface

Stacker guide

Assisting roller solenoid SOL6 MJ-1104

Relay

Sensors / Switches Finisher section

Entrance sensor S1

Release the latch, and then take off the entrance sensor

Transport sensor S2

Paddle home position sensor S3

Release the latch, and then take off the transport sensor

FIN board bracket

Shutter opening / closing sensor S4

Buffer tray home position sensor S5

Shutter opening

Closing sensor

Buffer tray home position sensor

Paper pusher home position sensor S6

Front alignment plate home position sensor S7

Paper pusher cam

Paper pusher plate

Rear alignment plate home position sensor S8

Stack exit belt home position sensor S9

Rear alignment

Plate home position sensor

Take off the belt from the stack transport motor

Stapler interference sensor S11 / Actuator

Stapler unit home position sensor S10

Stack exit belt Home position sensor

Remove the clip, and then take off the sta- pler base frame

Finishing tray paper detection sensor S12

Take off the finishing unit P.4-19 D Finishing tray unit

Remove 3 screws, and then take off the front

Front alignment plate guide

Sensor rail

Movable tray paper exist sensor S17

Movable tray paper-full sensor S16

Stationary tray paper-full sensor S18

Feeding sensor S22

Spacer Actuator Stationary tray paper-full sensor

Release the latch, and then take off the feed- ing sensor

Movable tray shift motor sensor S23

Feeding sensor

Movable tray shift motor sensor

Front cover switch SW1

Remove 2 screws, and then take off the front cover switch

Connection sensor S25

Connection sensor

Stationary tray opening/closing switch SW2

Spring Belt tension arm

Stapler interference switch SW3

Remove 4 screws, and then take off the switch bracket

Switch bracket

Connection switch SW4

Remove 4 screws, and then take off the upper saddle cover

Remark

Upper saddle cover

Remove 2 screws, and then take off the con Nection switch

Connection switch

Junction box paper detection sensor S26

Sensors / Switches Saddle section MJ-1104

Transport path-2 sensor S27

Transport path-3 sensor S28

Ejecting roller sensor S29

Stacker paper detection sensor S30

Stacker paper detection sensor

Exit sensor S31

Release the latch, and then take off the exit sensor

Saddle tray paper detection sensor S32

Exit sensor

Stacker home position sensor S33

Folding motor encoder sensor S34

Stacker guide

Folding motor

Folding blade home position sensor S35

Side alignment home position sensor S36

Paper holding home position sensor S38

Additional folding home position sensor S39

Folding carrier to the center

Sensor bracket

Exit transport sensor S41

Additional folding motor encoder sensor S42

Exit transport sensor

Additional folding motor encoder sensor

Saddle unit opening/closing switch SW5

Connector and take off the sensor bracket

Saddle unit opening/closing switch

Remove 2 screws, and then disconnect

Finisher control PC board FIN board

PC Boards / Discharge Brush

Remove 4 screws, and then take off the FIN board

Interface PC board I/F board

Remove 4 screws, and then take off the I/F board

Saddle control PC board SDL board

Front stationary tray

Discharge brush

Mylar

Rear stationary tray

Procedure for lowering the movable tray

Since the insertion of the screwdriver has

Released the driving gear of the movable tray

Stationary tray

Adjusting the Alignment Position

Adjusting for A4 size paper Adjusting for LT size paper

Remarks

B5 paper Vertical Adjustment sheet

Button1 Button2

Number of Blinking Adjustment Value

Adjusting the Stapling Position

LED3 LED2

Stapling/folding position adjustment in saddle unit

Sample

Phenomenon Contents Adjustment

Folding position adjustment

Number of blinking Adjustment value

Stapling position adjustment

Number of blinking Adjustment value

Saddle Stitch Skew Adjustment

Paper Transport Jam

EA10 Transport delay jam paper not inserted

Paper jam in entrance section

EA60 Early arrival jam

CB10 Entrance motor M1 abnormality

Paper jam in buffer unit-1

EA20 Paper transport jam in Finisher entrance sensor

Troubleshooting

Paper jam in buffer unit-2

EA28 Paper transport jam in Finisher paper holding delay

EA31 Transport path paper remaining jam in Finisher

ED16 Buffer tray home position error

CB12 Buffer roller drive motor M4 abnormality

Paper jam in finishing tray section

CB14 Paper pusher arm motor M10 abnormality

ED13 Front alignment plate home position error

ED14 Rear alignment plate home position error

ED15 Paddle home position error

EA70 Stack exit belt home position error

CC41 Paper pusher cam home position abnormality

EA32 Exit paper remaining jam

CB31 Movable tray paper-full detection error

ED12 Shutter home position error

Paper jam in movable tray section

CB30 Movable tray shift motor M12 abnormality

EA90 Saddle unit open error MJ-1104

EA40 Cover open error

Cover open jam

Troubleshooting

Paper Transport Jam in Saddle Stitch Section MJ-1104

Paper jam in Saddle Stitch Finisher transport section

EAA0

Paper remaining in Saddle Stitch Finisher

EAB0

Paper transport jam in Saddle Stitch Finisher

EF14 Saddle exit jam

EAB1

Short paper jam in Saddle Stitch Finisher

EF13 Saddle unit paper holding home position detection error

Paper jam in stack transport section

Paper jam in side alignment section

EF20 Saddle stacker jam

Troubleshooting

Paper jam in folding section

EF19 Saddle Stitch Finisher paper folding jam

Paper jam in additional folding section

Other Errors

Stapler related error

EA50

Stapling jam

CB51 Stapler shift home position error

CB60 Stapler unit shift motor M9 abnormality

Saddle Stitch Finisher stapler related error MJ-1104

EF11 Front saddle staple error

EF12 Rear saddle staple error

CBA0 Front saddle stapler home position error

CBB0 Rear saddle stapler home position error

Communication Related Error

When MJ-6102 is connected

Memory error

CB81 Flash ROM abnormality

CB91 Saddle flash ROM abnormality

Maintenance and Inspection Points

Front side Rear side

Symbols used in the checklist

Preventive Maintenance Checklist

Cleaning Lubrication/Coating Replacement Operation check

Items to check Cleaning Lubrication Replacement Operation

Buffer tray shaft

Finishing tray shaft Rack gear

EFS carrier shaft

Firmware Update

Update of CNV board

Connector Mark for ROM

Installation direction

Download jig

Update of FIN board

Preventive Maintenance PM / Firmware Update

Update of SDL board

Download jig

Preventive Maintenance PM / Firmware Update

Preventive Maintenance PM / Firmware Update

Harness Diagram

Finisher control PC board

Electric Circuit

Interface PC board

Opening/closing switch

Saddle control PC board

Circuit Diagram

Finisher control PC board 1. Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Interface PC board 1. Circuit Diagram

Circuit Diagram

Saddle control PC board 1. Circuit Diagram

2008, 2009 Toshiba TEC Corporation All rights reserved

Circuit Diagram

2008, 2009 Toshiba TEC Corporation All rights reserved

Circuit Diagram

2008, 2009 Toshiba TEC Corporation All rights reserved

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Circuit Diagram

Electric Circuit

PC board

Finisher controller PC board Interface PC board

Saddle control PC board

Electric Circuit

Ver.02

Ver.03

Ver.01

Revision Record