CHECKING FOR LEAKS

![]() WARNING

WARNING

Fire Hazard

Turn off the main gas supply before you try to stop a leak.

Be sure that all leaks are stopped before lighting pilots or burners.

Do not use an open flame to test for gas leaks.

Failure to follow these instructions could result in a possible fire, or explosion.

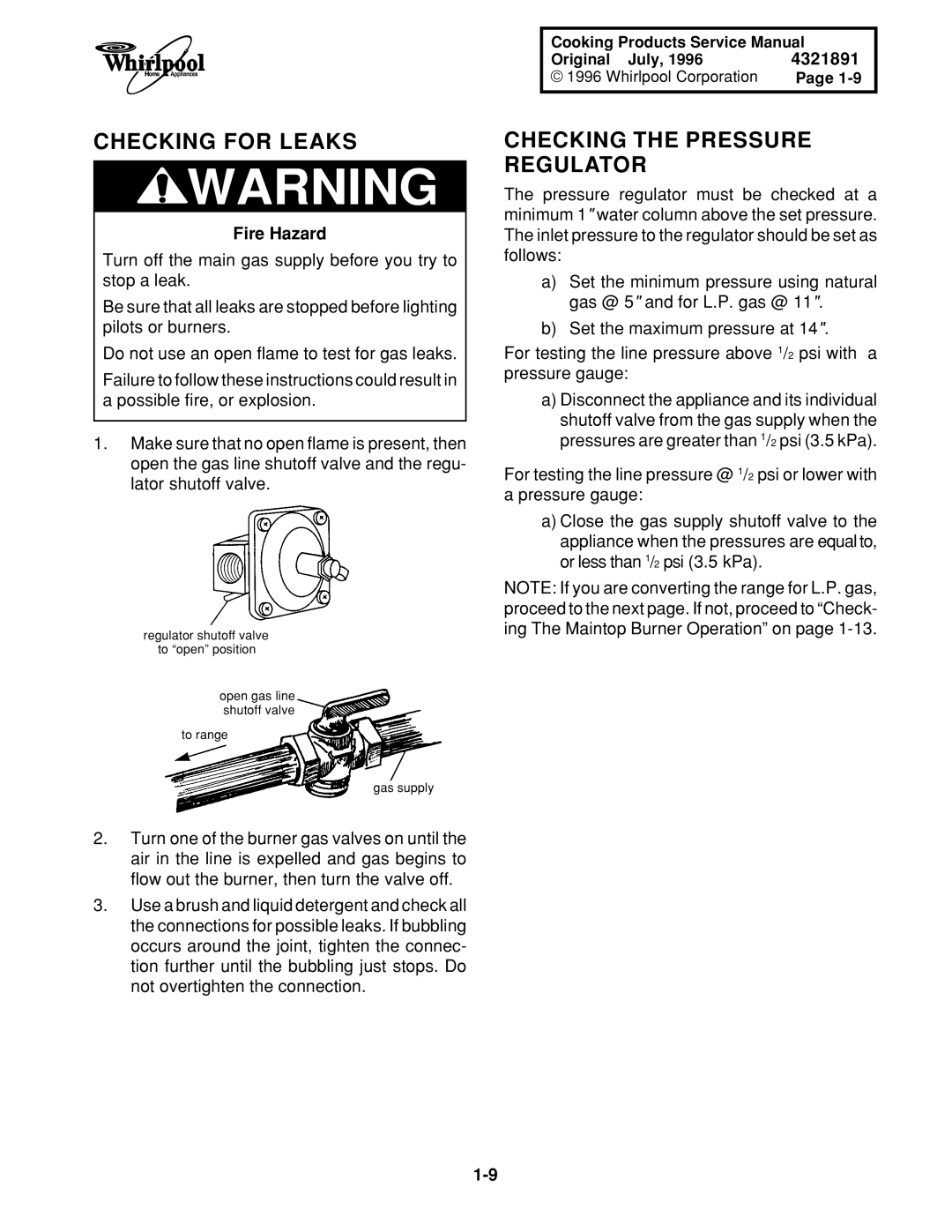

1.Make sure that no open flame is present, then open the gas line shutoff valve and the regu- lator shutoff valve.

regulator shutoff valve to “open” position

open gas line shutoff valve

to range

gas supply

2.Turn one of the burner gas valves on until the air in the line is expelled and gas begins to flow out the burner, then turn the valve off.

3.Use a brush and liquid detergent and check all the connections for possible leaks. If bubbling occurs around the joint, tighten the connec- tion further until the bubbling just stops. Do not overtighten the connection.

Cooking Products Service Manual

Original July, 1996 | 4321891 |

© 1996 Whirlpool Corporation | Page |

CHECKING THE PRESSURE REGULATOR

The pressure regulator must be checked at a minimum 1" water column above the set pressure. The inlet pressure to the regulator should be set as follows:

a)Set the minimum pressure using natural gas @ 5" and for L.P. gas @ 11".

b)Set the maximum pressure at 14".

For testing the line pressure above 1/2 psi with a pressure gauge:

a)Disconnect the appliance and its individual shutoff valve from the gas supply when the pressures are greater than 1/2 psi (3.5 kPa).

For testing the line pressure @ 1/2 psi or lower with a pressure gauge:

a)Close the gas supply shutoff valve to the appliance when the pressures are equal to, or less than 1/2 psi (3.5 kPa).

NOTE: If you are converting the range for L.P. gas, proceed to the next page. If not, proceed to “Check- ing The Maintop Burner Operation” on page