TOP BURNER GAS VALVES

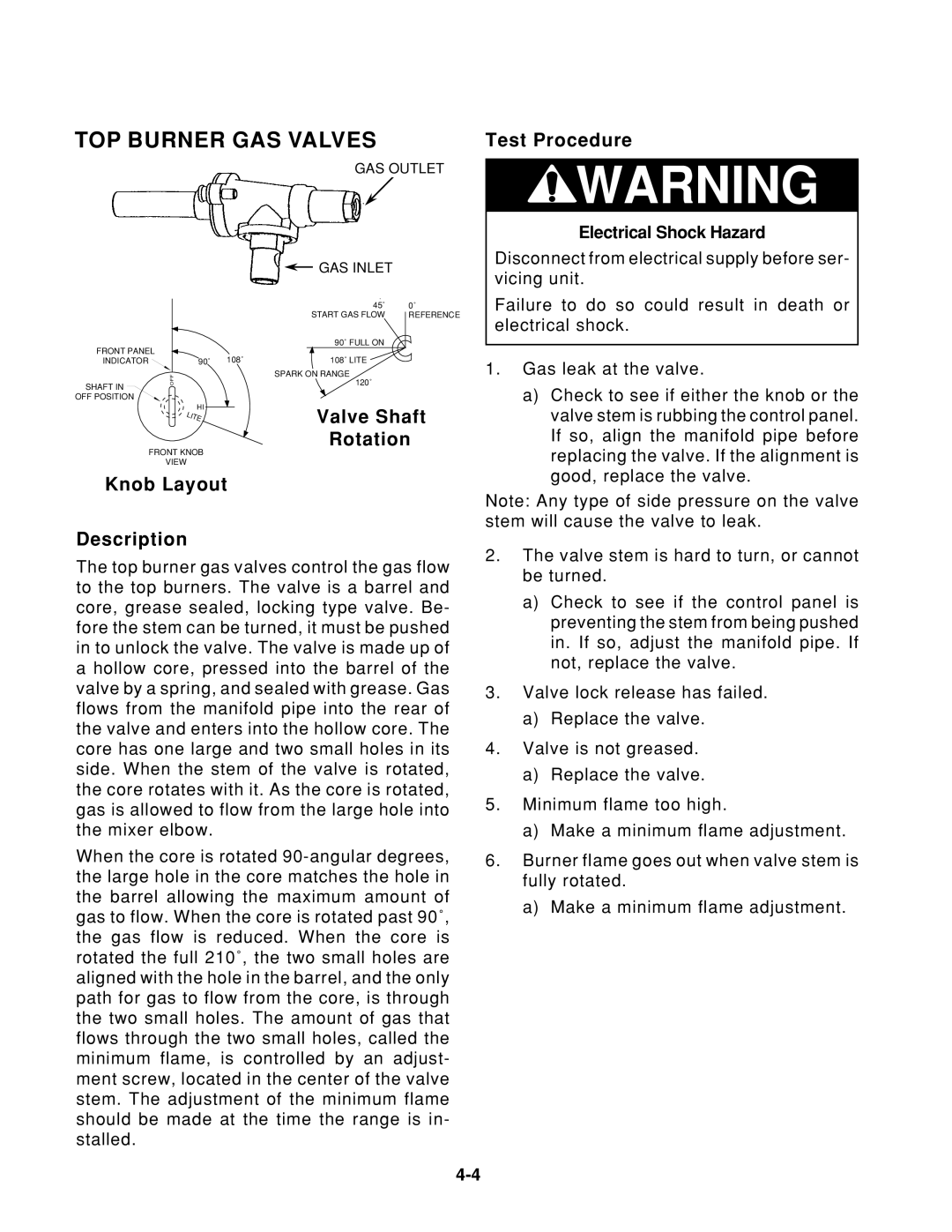

GAS OUTLET

GAS INLET

GAS INLET

45˚ | 0˚ |

START GAS FLOW | REFERENCE |

FRONT PANEL |

| 90˚ FULL ON | |

90˚ 108˚ | 108˚ LITE | ||

INDICATOR | |||

| OFF | SPARK ON RANGE | |

SHAFT IN | 120˚ |

Test Procedure

![]() WARNING

WARNING

Electrical Shock Hazard

Disconnect from electrical supply before ser- vicing unit.

Failure to do so could result in death or electrical shock.

1. Gas leak at the valve. |

OFF POSITION

HI

FRONT KNOB

VIEW

Valve Shaft

Rotation

a) Check to see if either the knob or the |

valve stem is rubbing the control panel. |

If so, align the manifold pipe before |

replacing the valve. If the alignment is |

good, replace the valve. |

Knob Layout

Note: Any type of side pressure on the valve stem will cause the valve to leak.

Description

The top burner gas valves control the gas flow to the top burners. The valve is a barrel and core, grease sealed, locking type valve. Be- fore the stem can be turned, it must be pushed in to unlock the valve. The valve is made up of a hollow core, pressed into the barrel of the valve by a spring, and sealed with grease. Gas flows from the manifold pipe into the rear of the valve and enters into the hollow core. The core has one large and two small holes in its side. When the stem of the valve is rotated, the core rotates with it. As the core is rotated, gas is allowed to flow from the large hole into the mixer elbow.

When the core is rotated

2.The valve stem is hard to turn, or cannot be turned.

a)Check to see if the control panel is preventing the stem from being pushed in. If so, adjust the manifold pipe. If not, replace the valve.

3.Valve lock release has failed.

a)Replace the valve.

4.Valve is not greased.

a)Replace the valve.

5.Minimum flame too high.

a)Make a minimum flame adjustment.

6.Burner flame goes out when valve stem is fully rotated.

a)Make a minimum flame adjustment.