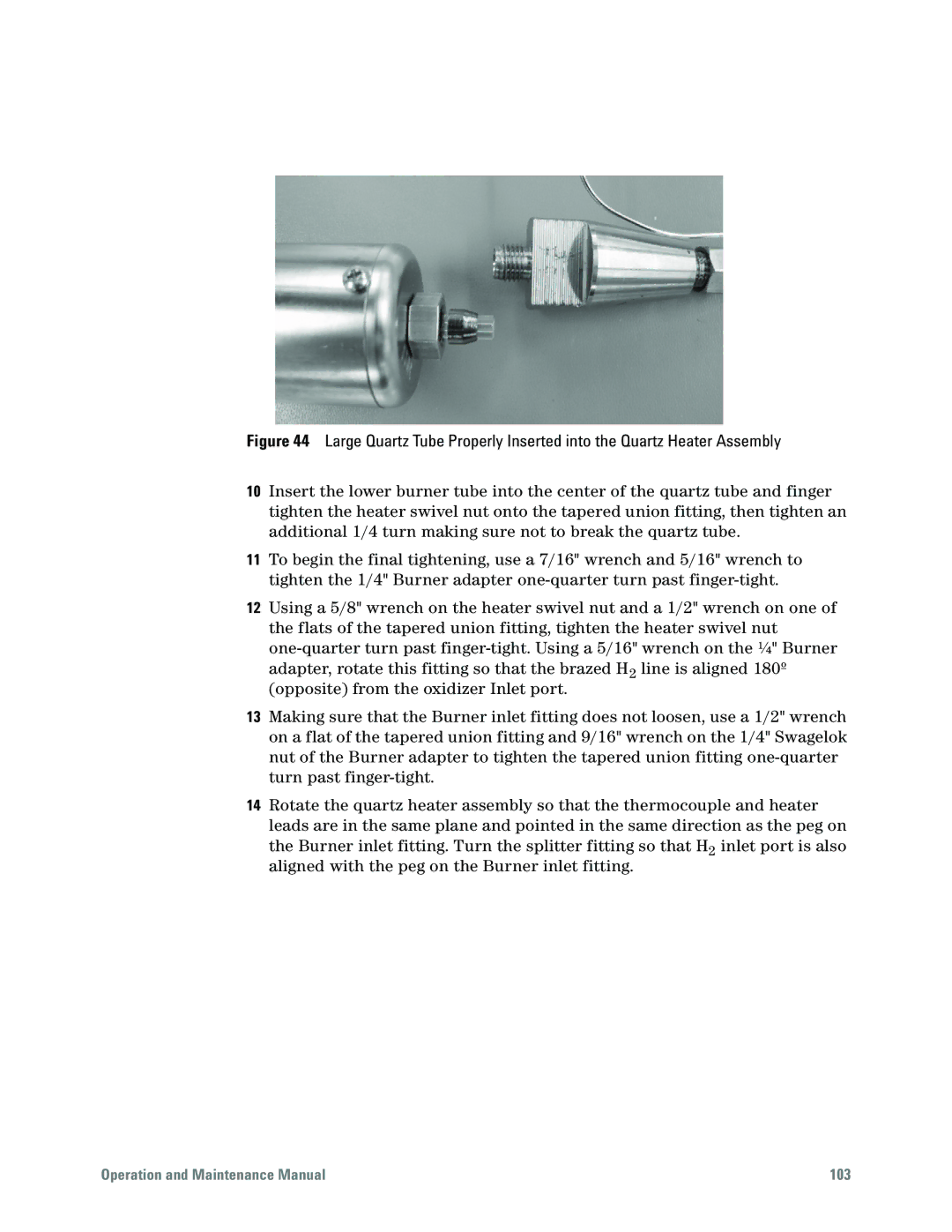

Figure 44 Large Quartz Tube Properly Inserted into the Quartz Heater Assembly

10Insert the lower burner tube into the center of the quartz tube and finger tighten the heater swivel nut onto the tapered union fitting, then tighten an additional 1/4 turn making sure not to break the quartz tube.

11To begin the final tightening, use a 7/16" wrench and 5/16" wrench to tighten the 1/4" Burner adapter

12Using a 5/8" wrench on the heater swivel nut and a 1/2" wrench on one of the flats of the tapered union fitting, tighten the heater swivel nut

adapter, rotate this fitting so that the brazed H2 line is aligned 180º (opposite) from the oxidizer Inlet port.

13Making sure that the Burner inlet fitting does not loosen, use a 1/2" wrench on a flat of the tapered union fitting and 9/16" wrench on the 1/4" Swagelok nut of the Burner adapter to tighten the tapered union fitting

14Rotate the quartz heater assembly so that the thermocouple and heater leads are in the same plane and pointed in the same direction as the peg on

the Burner inlet fitting. Turn the splitter fitting so that H2 inlet port is also aligned with the peg on the Burner inlet fitting.

Operation and Maintenance Manual | 103 |