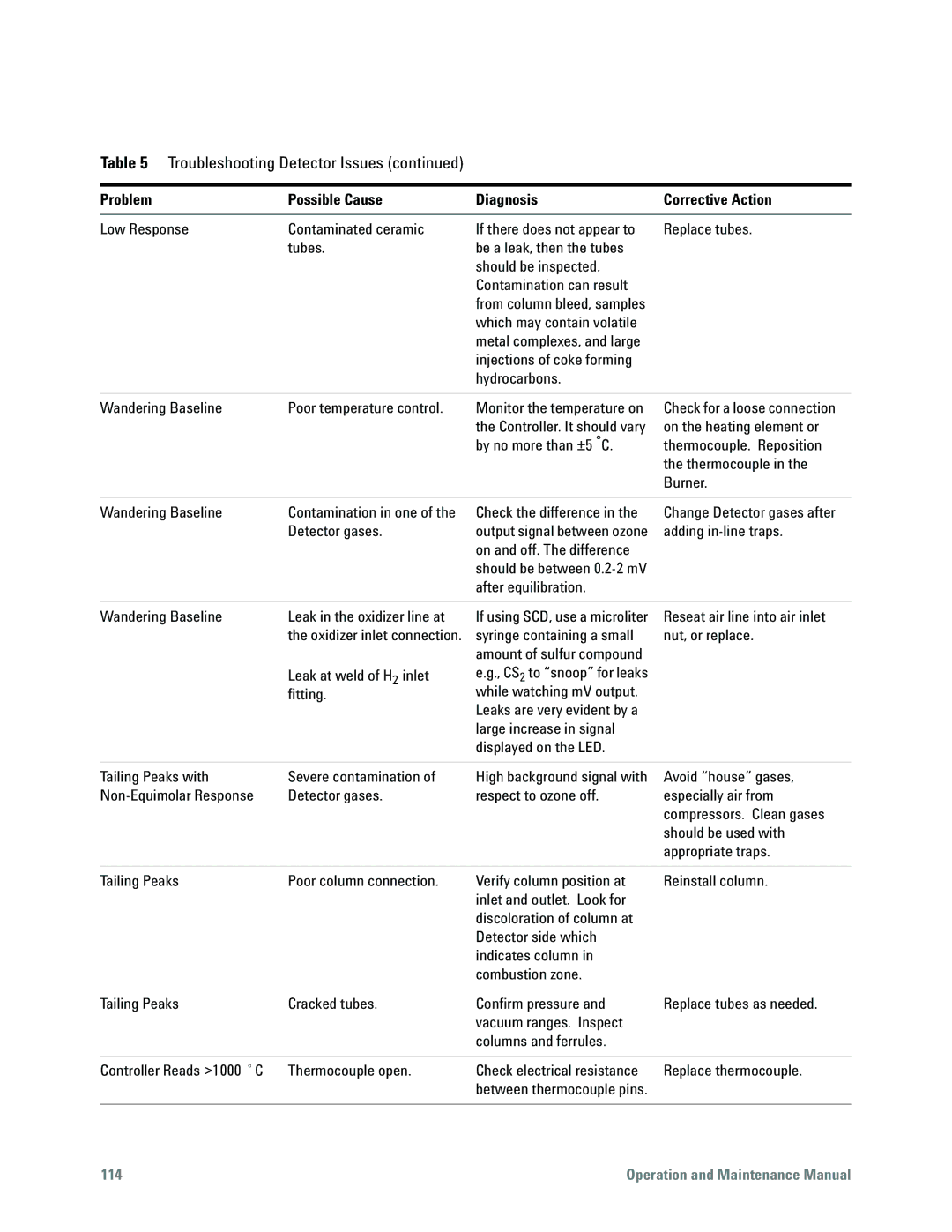

Table 5 Troubleshooting Detector Issues (continued)

Problem | Possible Cause | Diagnosis | Corrective Action |

|

|

|

|

Low Response | Contaminated ceramic | If there does not appear to | Replace tubes. |

| tubes. | be a leak, then the tubes |

|

|

| should be inspected. |

|

|

| Contamination can result |

|

|

| from column bleed, samples |

|

|

| which may contain volatile |

|

|

| metal complexes, and large |

|

|

| injections of coke forming |

|

|

| hydrocarbons. |

|

Wandering Baseline | Poor temperature control. | Monitor the temperature on |

|

| the Controller. It should vary |

|

| by no more than ±5 °C. |

Check for a loose connection on the heating element or thermocouple. Reposition the thermocouple in the Burner.

Wandering Baseline | Contamination in one of the |

| Detector gases. |

Check the difference in the | Change Detector gases after |

output signal between ozone | adding |

on and off. The difference |

|

should be between |

|

after equilibration. |

|

Wandering Baseline | Leak in the oxidizer line at |

| the oxidizer inlet connection. |

| Leak at weld of H2 inlet |

| fitting. |

If using SCD, use a microliter syringe containing a small amount of sulfur compound e.g., CS2 to “snoop” for leaks while watching mV output. Leaks are very evident by a large increase in signal displayed on the LED.

Reseat air line into air inlet nut, or replace.

Tailing Peaks with | Severe contamination of | High background signal with | Avoid “house” gases, |

Detector gases. | respect to ozone off. | especially air from | |

|

|

| compressors. Clean gases |

|

|

| should be used with |

|

|

| appropriate traps. |

|

|

|

|

Tailing Peaks | Poor column connection. | Verify column position at | Reinstall column. |

|

| inlet and outlet. Look for |

|

|

| discoloration of column at |

|

|

| Detector side which |

|

|

| indicates column in |

|

|

| combustion zone. |

|

|

|

|

|

Tailing Peaks | Cracked tubes. | Confirm pressure and | Replace tubes as needed. |

|

| vacuum ranges. Inspect |

|

|

| columns and ferrules. |

|

|

|

|

|

Controller Reads >1000 °C | Thermocouple open. | Check electrical resistance | Replace thermocouple. |

|

| between thermocouple pins. |

|

|

|

|

|

114 | Operation and Maintenance Manual |