Instruction

Page

Revision Date Description

AV-9000 Manual Revision Log

Page

AV-9000 Manual Prefix

Table of Contents

Display Programming Chart Prompts

Profilers

Controllers

Unpacking

Introduction and General Information

Installation of PEN Cartridge Assembly

AV- 9 0

Features

Operator Interface

RTD

Inputs

NNM

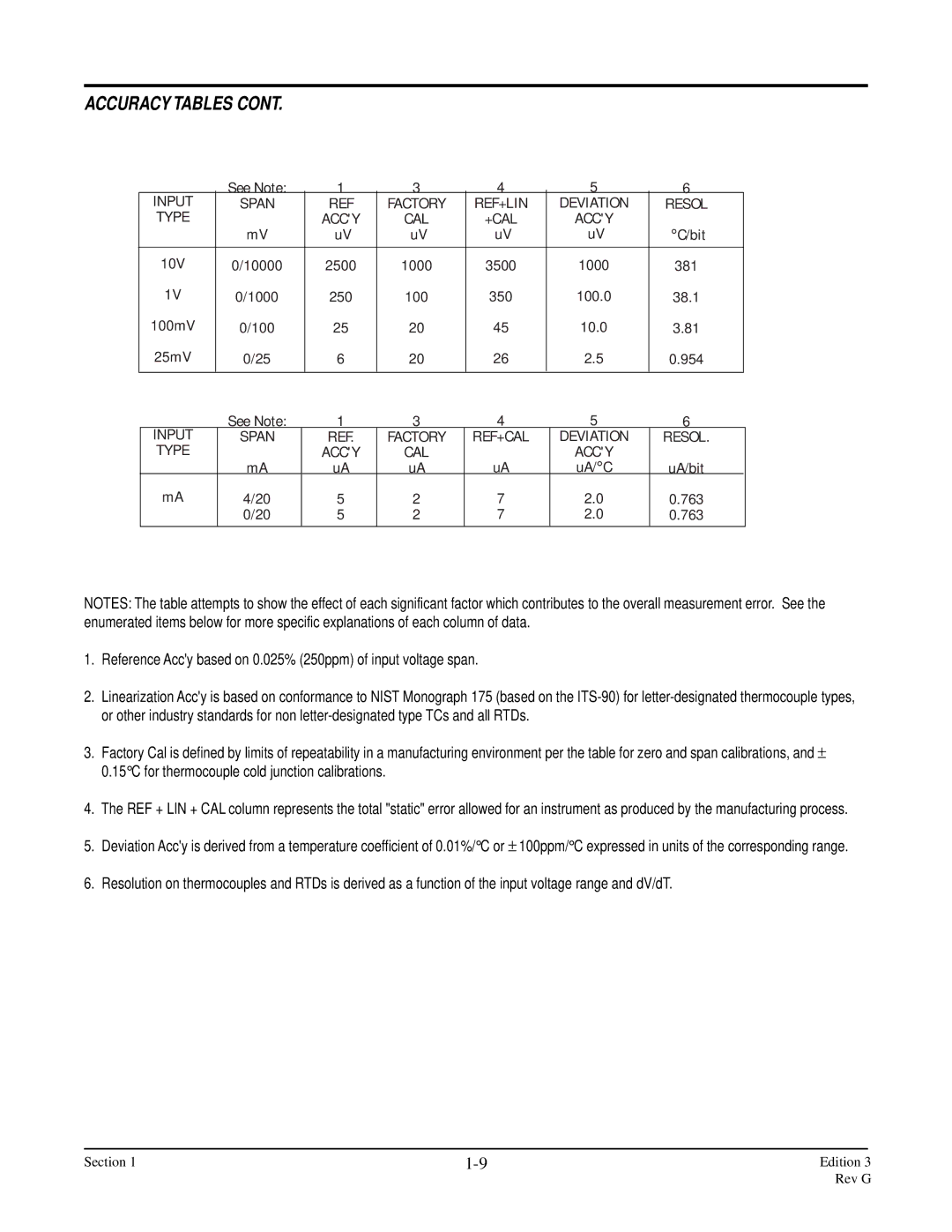

Range LIN Factory REF+LIN Deviation Resol

Sama

Input Span Factory REF+LIN Deviation Resol

Other Input Specifications

On Next

Current Outputs

Environmental and Operating Conditions

Warranty and Return Statement

Page

Installation and Wiring

17.04 432.82mm

Preparation for Wiring

MOV

Section Edition Rev G

Wiring Connections Inputs

Shipped CONFIGURATION/JUMPER Positioning

Universal Power Supply

AC Power Connections

Thermocouple Connections

RTD Connections

Voltage Connections

10A

Current Connections

11A

Switch Input Connections

SSR Driver Output

Wiring Connections Outputs

Spdt Relay Output

Isolated

Current Output

Non-isolated

Communications

4 24VDC Transmitter Power Supply

TB3 JP1 JP3

Instrument Modes

POWER-UP

Basics of Recorder Operation

Display KEY Disp

Keypad Function

Changing Values

Changing Parameter Settings Modify

General

Display

Display Details

Edition Section Rev G

Continuous Display

Chart Details

Sequential Display

Chart TAG Date Time

Chart TAG Time Date

None Just Continue Print Range List Print Scales

Alarm #1

Flow #1

Temp #1

Unit #1

Configure Chart Chart Type Used Rings only Chart TAG

Recorder Number

PEN/COLOR Blue Green Black RED RS Chart Divisions

Flow #1 Temp #1

Value DV1 IV2 IV4 DV2

Sequence of Events

Main Prompts

Getting Started

Input Value Configuration

Quick Start Procedure

Section Edition Rev G

Input

Software Reference/Record Sheet

Display TAG Input TYPE/RANGE Type Input Span

Constants

Custom Curves

Software Reference/Record Sheet

Parameter CC-3 CC-4

Parameter DV-1 DV-2 DV-3 DV-4

Derived Variables

Parameter DV-9 DV-10 DV-11 DV-12

PV-4

Process Variables

Remote SP Actuator

Controllers

Remote SP Source

Control Setpoints

Recording Method

Recorders

TOTAL-1 TOTAL-2 TOTAL-3 TOTAL-4

Totalizers

Leds

Timers

Relays

Current Outputs

Instrument Settings

Derived Actuator Equation

Derived Actuators

OI-02 OI-03

Operator Inputs

Operator Messages

Parameter CM-09 CM-10 CM-11 CM-12

Chart Messages

Software Reference/Record Sheet

CA2 F2 OFF State Text

CA2 F1 OFF State Text

CA2 F3 OFF State Text

CA2 F4 OFF State Text

CA3 F2 OFF State Text

CA3 F1 OFF State Text

CA3 F3 OFF State Text

CA3 F4 OFF State Text

CA4 F2 OFF State Text

CA4 F1 OFF State Text

CA4 F3 OFF State Text

CA4 F4 OFF State Text

Parameter SV-1 SV-2 SV-3 SV-4

Simulated Variables

Major Line PEN/COLOR if Select

Chart Programming

Minor Line PEN/COLOR if Select

Select a Color

Sequential Display Duration

Setpoint

Alarm Settings

Action Time Settings

Tuning Parameters

Enables & Passwords Password

Enables & Passwords

Entering Configuration

Configuration

U T S

Input Number

IVx Copy from Input

IVx Display TAG Input

= Initialized

If selection is NO, see Step If selection is YES

E,T,S N,C,G

MV, mA, Volt, Switch Contact go to . COMMS, go to Step

IVx TC Type

DIN

IVx RTD Type PT 100 .00385 DIN

IVx Degrees C / F

Upscale

IVx Sensor Break

IVx Input Range LOW

Units

100.000 Units

IVx Input Range High

IVx Pulse Rate High

Pulses / SEC

INT

IVx Register Type

IVx V / mA Conversion

Linear

IVx Other Units

IVx Display Units

IVx Decimal Position

Other

Units correspond to units configured in or

Units configured in step

IVx Range Limit High Units

Units correspond to

IVx Value Cutoff Type

IVx Exponent 500

None

IVx Cutoff Value

IVx Input Correct 100

IVx Input Correct

Seconds

IVx Value Filter

IVx Display Option

Both Modes

Closed

IVx Closed / 0 Descr

IVx Open / 1 Descr

Open

Constants

S T a N T S

Constant Number

Custom Curves

R V E S

CVx Value 00000 E

Output

CCx Decimal Position

Input

100

CCx Number of Points

CCx Point Pair

Derived Variables

DV Number

R I a B L E S

R I

DVxx Display TAG DER VAL

DVxx Function

None Used

DVxx Input

OUTPUT12

R I V E D R I a B L E S

OUTPUT22

OUTPUT32

R I V E D R I a B L E S

None / OFF

None / OFF

DVxx Reset Actuator

DVxx Units Descrip

Other

DVxx Decimal Posit

DVxx Display Units

Value Filter Seconds

DVxx

DVxx Display Option

Both Modes

Derived Variable Function

Actuator Reset Output

Input Prompt

LIN Linear Input Prompt

Actuator Reset Output = C*SQRT DP*PRES / TEMPR*COMP

Actuator Reset Output =C*F*SQRT PRES/TEMPR*COMP

Polynomial Input Prompt

Linear Mass Flow AGA 3 Lineaer GAS Flow Input Prompt

Relative Humidity Input DBT Prompt

Actuator Reset YES Prompt

Input WBT Prompt

Input Baro Prompt

Actuator Reset YES Prompt Dvxx Reset Actuator Output

High Peak Input Prompt Dvxx Input Actuator Reset YES

Reset Output

LOW Peak Input Prompt

Convert C to F Input Prompt

Actuator Reset Output = C*F* TEMPH-TEMPL

BTU Input Prompt

Input Temph Prompt

Process Variables

Process Value Number

PVx Copy / Initialize

PVx Copy from PV

O C E S S R I a B L E S

= Initialize

PVx Display TAG

PVx Display Units

PVx Input

None Used

PV Decimal Position

PVx Value Filter

PVx Other Units

L E S

Not Displayed Continuous Mode Sequential Mode Both Modes

PVx Display Option

PVx Display Filter

O C E

Ax1 Alarm Type

R I a

E S

Ax1 Time Base

O C

PER SEC

Ax1 Hysteresis Units

Rate

Ax2 Time Base

Ax2 Hysteresis

To units configured Process Variables

S S

To Units configured

Ax3 Time Base

PER SEC

Ax4 Time Base

Ax4 Alarm Type

Ax4 Hysteresis

PVx Loop Alarm Inhibit

PVx Loop Alarm Time

Rx Copy / Initialize

C O R D E R S

Recorder Number

Recorders

If selection was NO, proceed to step If selection was YES

Rx Recorder TAG

Rs Copy from Recrder

Rx Value to Record

D E R S

Rx Chart Divisions Rings

Rx Recording Method

Drag MIN to MAX

Rx Zone 1 High

Rx Zone 1 LOW

Division

Rx Span 1 LOW 0 units

Rx Span 1 High Units

Divisions

Rx Zone 2 High

Rx Scale 1 Interval

= no Scales

Rx Scale 2 Interval

Rx Span 2 High 0 units

Rx Filter

Totalizers

Tx Copy / Initialize

Totalizer Number

Total

T a L I Z E R S

Tx Display TAG

Pulses

Tx Input Value

Tx Time Base

R S

T a

Tx Total is Flow

TIMES1

Tx Totalizer Type

Tx Display Option

Continuous

Tx Display Format

Tx LOW Flow Cutoff Units

Tx Totalizer Preset Units

I Z E R S

None / OFF

None / OFF

Tx Pulsed Output

Tx Pulse Every Units

TMx Display TAG

Timer Number

Timer

TMx Timer Period Format

TMx Timer Type

OFF

TMx Time Format

OP INP

Preset

DA3 DA4

DA6 DA7

LED Number

TMx Display Option

D S

State or on OFF

Relay Number

Relay x Usage

L a Y S

Preset Total PO1

Time Proportioning

Relay x T.P. Value

Relay x Cycle Time

COx Source

R R E N T T P U T S

Current Output

Current Outputs

20mA

Units

COx Output on Error

Instrument TAG Recorder #1

Display Option Sequential Mode

Instrument Settings

Time TIME/DATE

OUTPUT42 Reset

Enter

Relay

Alarming on Actuator On / Continuous

Control on Actuator On / Continuous

Chart Rotation Trend Data Collect ALT Chart Speed

Date Display Format

M E N T

MM / DD / YY

Time Display Format AM / PM

Current DAY

T T I N G S

Current Time

Format 900 AM

Slave

Communications Mode

Comms BIT Rate

Comms Address

R I V E D

T R T T I N G S

T U a T O R S

Comms Parity ODD

Derived Actuators

Derived Actuator

DAxx Copy / Initialize

R I V E D T U a T O R S

DAxx Copy from DA

No YES

DAxx

OIxx Copy / Initialize

R I V E D T U a T O R S E R a T O R

Operator Input

Operator Inputs

OIxx Prompt Text

OIxx Copy from OI

Continuous Momentary

E R a T O R U T S

OIxx Actuation Style

OIxx When Displayed

OIxx Power UP State

E R

Same

Operator Messages

Operator Message

OMxx Copy / Initialize

= Initialize

OMxx Copy from OM

None / OFF

OMxx Line 1 Text

OMxx Display Mode

Message

OMxx Line 2 Text

Chart Messages appears

Chart Messages

E R a T O R A R T S a G E S

CMxx Copy / Initialize

CMxx Copy from CM

= Factory Default

None / OFF

CMxx Message Text

S S a G E S

IV1 IV2

CMxx Value

PV1 PV2 PV3 PV4 DV1

CMxx Time / Date Stamp

A R T S a G E

CMxx Orientation

Horizontal

SVx Display TAG

SVx Type

SIM VAL

100

SVx Other Units

R I a B L

SVx Display Units

SVx Decimal Position

102

SVx Range LOW Units

SVx Range High

Minutes

SVx Period 1 / Freq

SVx Display Option

103

T t t t t t t t t t t t t t t t t t

Display Programming

Select Setpoints

Cx Output

Nnn%

Select Manual Values

AMM used, default 1 VAL

AMM used, default Continuous

Duration n Seconds SEQUENCE, AMM used, default

Nnnnnnnnnnyyyyyyyyyy AMM used, see below

Change Chart

Chart Prompts

Chart Configuration

Chart Type Used Rings only

Normal Speed Hour

Chart TAG Unit #1

Normal Speed

HRS / REV

Blank Major Periods

Minor Time Periods

Major Time Periods

Match Scale Color Select a Color

Major Line PEN / Color Match Scale Color

Minor Line PEN / Color RED

Minor Line PEN / Color Match Scale Color

Black Violet

Date PEN / Color RED

Blue Green RED

Chart TAG PEN / Color RED

Action on NEW Chart None Just Continue

Stop After 1 REV

None Just Continue Print Range List Print Scales

Chart Rotation

Rotate Chart Actuatr

Collect Data Actuatr

Chart Speed Prompt Prompt not Displayed

Chart Rotation Prompt Displayed

Trend Data Collect Prompt not Displayed

Prompt not Displayed Prompt Displayed

Alarms for PV Number

Alarm Settings

100 Units

Ax2 Setpoint

Ax3 Setpoint 100 Units

Variables

Ax4 Setpoint 100 Units

Examples Time

Action Time Settings

Time 1 TAG Start Time

Date

Time

Format

Time 2 TAG Stop Time

Time

Will read current date

DAY of Week Actuator SUN

Not Displayed

DAY of Month ACT

Time Display Option Not Displayed

Change ALL Enables

Enables & Passwords

Disabled Enabled Toggle

Change ALL to Toggle

Disabled Enabled

Action Time Settings

Disabled Enabled

Profile Entry Only on Profiles

Setpoint Changes

Alarm Settings

Tuning Parameters

Operator Inputs Conf

Configuration

Derived Actuators

Simulated Variables

Chart Messages

Operator Messages

Calibration

Chart Prompts

Test

Operator Inputs

Chart Configuration

Display Prompts

Control State Access

System Prompts Password REQ

Enables & Passwords PASSWORD0

Display Prompts PASSWORD0

Chart Prompts PASSWORD0

10-1

Test

10-2

Relay Test

Display Test

LED Test

Keypad Test

10-3

ESC key will exit this test

10-4

Chart Demonstration

10-5

11-1

Specifications listed below

Calibration

Important Notes

11-2

11-3

11-4

For Inputs Board Position

11-5

Cold Junction Calibration

11-6

Parameter Defaults

Chart Calibration

CAL Which mA Output

Milliamp Output Calibration

11-7

Solenoid Calibration

Calibration Defaults

11-8

Consult Factory

11-9

13-1

Controllers

Words

Example

13-2

13-3

Controller Number

Entering Controllers

=INITIALIZEX

Cx COPY/INITIALIZE

Cx Control Type

Standard

NONE/OFF

Cx Output 1 Type

Cx Output 2 Type

13-5

Units

Cx OUT 1 Hysteresis

Cx OUT 2 Hysteresis

100%

13-7

On Error

Upper Limit

13-8

MIN

13-9

Cx Manual Actuator CAxF1

13-10

Cx Main SP Source SPx

13-11

Cx Remote SP Actuatr CAxF5

13-12

None Used

13-13

Cx Second SP Actuatr CAxF3

13-14

Cx Remote SP Ratio 000

13-15

Cx Remote SP Bias

None Used

13-16

Cx Feedforward LOW

13-17

Not Displayed

13-18

Setpoint Number

Setpoint

SPx Prompt Text

SPx Display Units

SPx Other Units

SPx Upper Limit

SPx Decimal Position

SPx Lower Limit

13-20

13-21

SPx Display Option

Not Displayed

CA1 Line Text

Control State Access

Controller

13-22

SP1/SP2

CAx Line 2 Text

CAx F1 KEY Usage Cx AUTO/MANUAL

13-23

Controller

CAx F1 Line 1 Text

CAx F1 on State Text

Manual

13-25

CAx F2 Line 1 Text

CAx F2 OFF State TXT

13-26

CAx F2 on State Text

SP2

CAx F3 on State Text

CAx F4 KEY Usage

Not Used

13-28

CAx F4 Line 1 Text

CAx F5 OFF State TXT

CAx F5 Line 1 Text

Local

13-29

13-30

CAx F5 on State Text

Remote

13-31

Cx Copy from Contrlr

=FACTORY Default

Cx SP Ramp Rate Units/HR

13-32

13-33

Cx OUT 1 Prop Band Units

13-34

Cx OUT 1 Shift Units

Cx OUT 2 Shift Units

13-35

Cx Integration Band Units

Cx Integration Shift Units

Cx OUT 2 Auto Reset

Cx OUT 1 Auto Reset

REPEATS/MIN

13-36

Minutes

Cx OUT 2 Rate

Cx OUT 1 Rate

Minutes

Following are Repeated for Each Segment

Profile Entry

14-1

14-2

14-3

14-4

Profile Settings

Current Segment

14-5

14-6

Profile Entry

Profile Control

14-7

Continue

14-8

14-9

14-10

14-11

14-12

14-13

14-14

14-15

14-16

14-17

Appendix a Board Layouts

Figure A-1 Power Supply Board

Figure A-2 Mother Board

3 +

Figure A-3 RELAY/SSR Board

JU5 JU12

JU13 JU14 JU3 JU15

JU11 JU2 TB1 JU16 JU6

Figure A-5 Motor Driver Board

Figure A-6 Current Output Board

Figure A-7 Transmitter Power Supply Board

485 Aux

Main

232 Aux

Thermocouple

Appendix B Ranges

JU7/JU8 Position Type Operating Range

Plii

Sama

RTD

USA

Alternate Speed

Appendix C Reference Section

Actuators

Chart Prompts

Chart Key

Choice

Chart Rotation Actuator

Edition

Display Sequence

Disp Key

Display Prompts Section

Edition

Major time lines

Minor time lines

Normal Display mode

Print interval

Prompt section

Prompt

Scale values

Rings and Time Lines See Chart Type Used

Scale lines

Tag

Sensor break

Text

Count Down Preset

Time between print cycles see Print interval

Hoursminutesseconds

Trend data collection

Trend Data Collect Actuator

Value

Zone

Appendix C Edition Rev G

CPM

Appendix D Examples

Exhaust FAN

END

FAN OFF

FAN on

Preempt to OFF

Total Exceed Preset

Alarm 1 Pressure HI

Derived Actuators DA1 Item Not Reset

Not

DA2

Narrow

Appendix E Accuracy Tables

Wide

385 160/480 025

Factory REF+CAL Deviation Resol Ranges Accy

Linear

Factory REF+LIN Deviation Resol Ranges Accy CAL +CAL