4 HP

Installation, Operation Maintenance Instruction

Otherwise, electric shock could occur

Safety Instructions

Otherwise, fire or accident could occur

Otherwise, you may get an electric shock

Otherwise, fire could occur

Otherwise, it could result in a secondary accident and fire

Operating Precautions

Page

Page

Contents

106

100

104

105

Motor Rating1 Output Capacity2 kVA

User Selection Guide Actionmaster Specifications

230V Class 0.5~5.4HP

460V Class 0.5~ 5.4HP

Control

Control Method

Environmental Conditions

Installation

Inspection

008

Installation

Other Precautions

130 118 128 117.5 152.9

Dimensions

Inverter

100 128 117.5 130.9

SV037ACtionMaster 150 138 128 117.5 155.0

Mccb

Basic Wiring

Wiring Power Terminals Precautions on Wiring

Power Terminals

Grounding Warning

Motor should be connected to the U, V, and W Terminals

Wires and Terminal Lugs

Screw Ring Terminals Wire6 Inverter Torque5 Mm2

Kgf·cm/lb-in

Control Terminals

30A 30C 30B

Control Circuit Terminal

Wiring Control Terminals Precautions on Wiring

Inside Inverter

Description

Keypad Wiring the Keypad

Keypad Connector Pin Configuration Inverter Side

Pin No

RUN Key

Keypad and Parameter Group Setting

Operation

Segment

Operation

Parameter Setting and Change

Procedures

Setting the DRV Group Data

Trip Current

Adjusting Function and I/O Group Data

Example Changing the F5 data to

Frequency

Group Name Description

Parameter Group

Moving Through DRV Group Codes

Moving Through I/O Group Codes

Moving Through Function Group Codes

Operation From Control Terminal

Operation

Operation From Keypad and Control Terminal

Operation From Keypad

Drive Group DRV

Parameter List

Parameter List

Function Group 1 FU1

FU1-53

50 / 60 Hz FU1-37

FU1-52

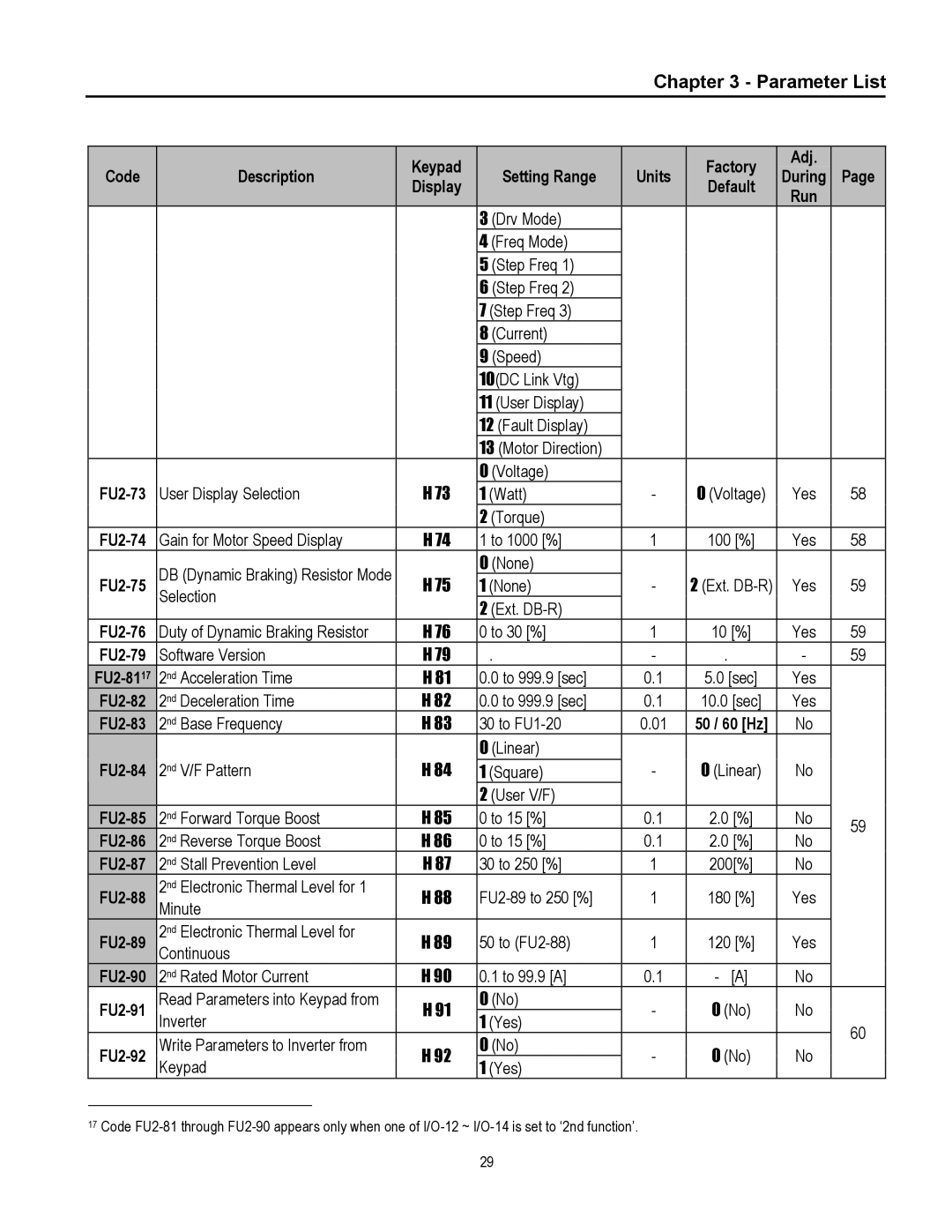

Function Group 2 FU2

FU2-36

FU2-3214

FU2-33

FU2-3415

FU2-89

FU2-83

FU2-85

FU2-88

50 /60 Hz

Input/Output Group I/O

Yes Acceleration Time To 999.9 sec

Yes For Step Frequency Deceleration Time To 999.9 sec

Yes For Step Frequency Acceleration Time To 999.9 sec

Yes Deceleration Time To 999.9 sec

Yes Reference Free Run

Acceleration Time To 999.9 sec

Yes FM Frequency Meter Output Current Selection Voltage

Stall

Bit

Yes Modbus-RTU

DRV-01 Acceleration Time DRV-02 Deceleration Time

Related Functions DRV-04 Freq Mode FU1-20 Max Freq

Parameter Description

DRV-00 Output Frequency

Select the source of frequency setting

Parameter Description DRV DRV-03 Drive Mode Run/stop Method

DRV-04 Frequency Mode Frequency Setting Method

Select the source of Run/Stop command

DRV-09 Motor Speed

Parameter Description DRV

DRV-05 ~ DRV-07 Step Frequency 1 ~

DRV-08 Output Current

DRV-11 User Display Selection

DRV-12 Fault Display

Fault Contents

DRV-10 DC Link Voltage

Page

FU1-03 Run Prevention

Function 1 Group FU1

Parameter Description FU1

FU1-00 Jump to Desired Code #

Selects the stopping method for the inverter

FU1-07 Stop Mode

Stop Mode ‘Free-run’

Output Frequency FU1-22 Time Output Voltage

Freq. limit ‘Yes’

FU1-30 ~ FU1-37 User V/F Frequency and Voltage

Parameter Description FU1 FU1-29 Volts/Hz Pattern

FU1-39 Energy Save Level

FU1-38 Output Voltage Adjustment

Motor i2t Characteristic Curve

FU1-54 Overload Warning Level FU1-55 Overload Warning Time

St bit

FU1-59 Stall Prevention Mode Selection

This code is used to exit a group. Press Func key to exit

Parameter Description FU1 FU1-99 Return Code

FU2-07 Dwell Frequency FU2-08 Dwell Time

Function 2 Group FU2

Parameter Description FU2

FU2-00 Jump to Desired Code #

FU2-10 ~ FU2-16 Frequency Jump

FU2-19 Input/Output Phase Loss Protection Bit Set

Setting Range

FU2-20 Power on Start Selection

FU2-21 Restart After Fault Reset

FU2-19 Phase Loss Protection Select

FU2-22 Speed Search Select

Motor Speed Time Output Frequency Output Voltage

FU2-39 Carrier Frequency

Output frequency = Reference freq. + Delta freq

Parameter Description FU2 FU2-40 Control Method Selection

This is to select the control method of inverter

Delta freq

FU2-70 Reference Frequency for Accel/Decel

FU2-74 Gain for Motor Speed Display

FU2-72 Power On Display

Parameter Description FU2 FU2-71 Accel/Decel Time Scale

FU2-73 User Display Selection

Displays the software version

FU2-76 Duty of DB Dynamic Braking Resistor

FU2-79 Software Version

FU2-81 ~ FU2-90 2nd Motor Related Functions

FU2-99 Return Code

FU2-91 Parameter Read FU2-92 Parameter Write

FU2-93 Parameter Initialize

FU2-94 Parameter Write Protection

Parameter Description FU2

00 Jump to Desired Code #

01 ~ I/O-05 Analog Voltage Input V1 Signal Adjustment

06 ~ I/O-10 Analog Current Input I Signal Adjustment

Parameter Description I/O

Following table shows the selection in I/O-48

11 Criteria for Analog Input Signal Loss

Step Parameter Speed-H Speed-M Speed-L

Speed-L, Speed-M, Speed-H

Time

DC-Brake

2nd Function

Accel/Decel Parameter

Ext Trip-A

Wire

V1-Ext

Up, Down

Analog Hold

15 Terminal Input Status 16 Terminal Output Status

20 Jog Frequency

21 ~ I/O-24 Step Frequency 4, 5, 6

Multi-Accel/Decel Time Operation

40 FM Frequency Meter Output 41 FM Adjustment

25 ~ I/O-38 1st ~ 7th Accel/Decel Time

44 Multi-function Output define MO-MG

42 FDT Frequency Detection Level 43 FDT Bandwidth

FDT-4

FDT-1

FDT-2

FDT-3

Stall

IOL

46 Inverter Number 47 Baud Rate

45 Fault Output Relay 30A, 30B, 30C

99 Return Code 7-Segment Keypad

50 Communication Protocol Selection

Introduction

Specifications

MODBUS-RTU Communication

System configuration

Installation

Items Specifications

Connecting the communication line

Exception Code Name

Operating

Communication Protocol Modbus-RTU

Function Code Name

Normal Response Acknowledge Response

Basic Format Command Message Request

Error Response Negative Acknowledge Response

Communication Protocol CMC-BUS Ascii

Negative Acknowledge Response

Detail Communication Protocol

Acknowledge Response

Request for Registration of ‘n’ numbers of Address

Request for Write

Error Code

Common Parameter Description Unit Read/Write Data value HEX

Parameter Code List

Value

Parameter Description

Read/Write Data value HEX

Description Default Max. value Min. value Unit

SS I-Gain

Retry delay

630A

180

Group Parameter

Description Default Max. value Min value Unit

Parameter Description Default Max. value Min value Unit

Refer to this chapter when a trouble is occurred

Troubleshooting

MODBUS-RTU Communication

Space

Ascii Code List

Character Hex

Display Protective Description

Troubleshooting & Maintenance

Fault Display

Troubleshooting & Maintenance

Fault Inverter Fault Reset

Protective Cause Remedy

Fault Remedy

Condition Check Point

Module

How to Check Power Components

Elements Test Polarity Measured Value

Short

Periodical Inspection

Maintenance

Precautions

Routine Inspection

Inspection Method Criterion Measuring Instrument

Daily and Periodic Inspection Items

Period Inspection

Fan

Troubleshooting & Maintenance

400V Class Model Number 004-4 008-4 015-4 022-4 037-4

Options

Braking Resistor

DB Resistor2

Phase

230V, or Phase 230/460V 50/60Hz

Options

Unit mm

DIN Rail Base

103

Use Related Parameter Code

Appendix a Functions Based on the USE

Inverter

Appendix B- Peripheral Devices

CD 73/23/EEC and CD 89/336/EEC

Declaration of Conformity

EN 55022

Safety of information technology equipment

Characteristics of information technology equipment

EN 50178

Essential Requirements for CE Compliance

EMC Installation Guide

109

Footprint Filters

RFI Filters Footprint Standard for ACtionMaster Series

Revision Date Remarks

Revision History

112

Cleveland Motion Controls