INSTRUCTION

HANDBOOK

9. Installation

01201138 | 0107 | 31 |

|

|

|

Notice | Date | Page |

|

|

|

9

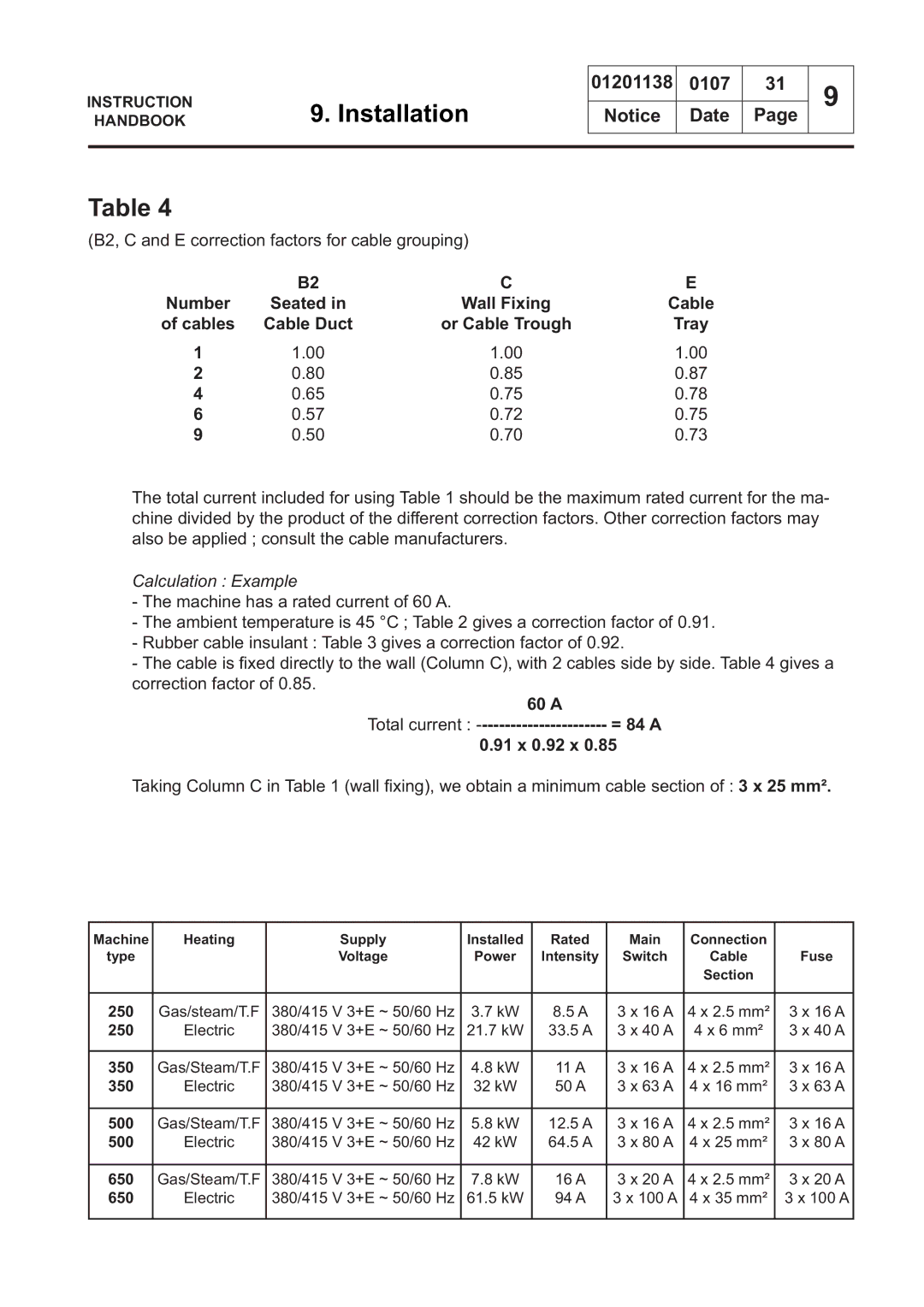

Table 4

(B2, C and E correction factors for cable grouping)

| B2 | C | E |

Number | Seated in | Wall Fixing | Cable |

of cables | Cable Duct | or Cable Trough | Tray |

1 | 1.00 | 1.00 | 1.00 |

2 | 0.80 | 0.85 | 0.87 |

4 | 0.65 | 0.75 | 0.78 |

6 | 0.57 | 0.72 | 0.75 |

9 | 0.50 | 0.70 | 0.73 |

The total current included for using Table 1 should be the maximum rated current for the ma- chine divided by the product of the different correction factors. Other correction factors may also be applied ; consult the cable manufacturers.

Calculation : Example

-The machine has a rated current of 60 A.

-The ambient temperature is 45 °C ; Table 2 gives a correction factor of 0.91.

-Rubber cable insulant : Table 3 gives a correction factor of 0.92.

-The cable is fi xed directly to the wall (Column C), with 2 cables side by side. Table 4 gives a correction factor of 0.85.

| 60 A |

Total current : | |

| 0.91 x 0.92 x 0.85 |

Taking Column C in Table 1 (wall fi xing), we obtain a minimum cable section of : 3 x 25 mm².

Machine | Heating | Supply | Installed | Rated | Main | Connection |

|

type |

| Voltage | Power | Intensity | Switch | Cable | Fuse |

|

|

|

|

|

| Section |

|

|

|

|

|

|

|

|

|

250 | Gas/steam/T.F | 380/415 V 3+E ~ 50/60 Hz | 3.7 kW | 8.5 A | 3 x 16 A | 4 x 2.5 mm² | 3 x 16 A |

250 | Electric | 380/415 V 3+E ~ 50/60 Hz | 21.7 kW | 33.5 A | 3 x 40 A | 4 x 6 mm² | 3 x 40 A |

|

|

|

|

|

|

|

|

350 | Gas/Steam/T.F | 380/415 V 3+E ~ 50/60 Hz | 4.8 kW | 11 A | 3 x 16 A | 4 x 2.5 mm² | 3 x 16 A |

350 | Electric | 380/415 V 3+E ~ 50/60 Hz | 32 kW | 50 A | 3 x 63 A | 4 x 16 mm² | 3 x 63 A |

|

|

|

|

|

|

|

|

500 | Gas/Steam/T.F | 380/415 V 3+E ~ 50/60 Hz | 5.8 kW | 12.5 A | 3 x 16 A | 4 x 2.5 mm² | 3 x 16 A |

500 | Electric | 380/415 V 3+E ~ 50/60 Hz | 42 kW | 64.5 A | 3 x 80 A | 4 x 25 mm² | 3 x 80 A |

|

|

|

|

|

|

|

|

650 | Gas/Steam/T.F | 380/415 V 3+E ~ 50/60 Hz | 7.8 kW | 16 A | 3 x 20 A | 4 x 2.5 mm² | 3 x 20 A |

650 | Electric | 380/415 V 3+E ~ 50/60 Hz | 61.5 kW | 94 A | 3 x 100 A | 4 x 35 mm² | 3 x 100 A |

|

|

|

|

|

|

|

|