Epsilon

High Performance Gains

Enabling High Performance Gains fundamentally affects the closed loop operation of the drive and greatly modifies the effect of the Response parameter. High Performance Gains are most beneficial when the Inertia Ratio and Friction parameters are accurate.

High Performance Gains, when enabled, make the system less forgiving in applications where the actual inertia varies or the coupling between the motor and the load has excessive windup or backlash.

Note

When using an external position controller, High Performance Gains should not be enabled.

Feedforwards

Feedforward gains are essentially open loop gains that generate torque commands based on the commanded velocity, accel/ decel and the known load parameters (Inertia Ratio and Friction). Using the feedforwards reduces velocity error during steady state and reduces overshoot during ramping. This is because the Feedforwards do not wait for error to build up to generate current commands.

Feedforwards should be disabled unless the absolute maximum performance is required from the system. Using them reduces the forgiveness of the servo loop and can create instability if the actual inertia and/or friction of the machine varies greatly during operation or if the Inertia Ratio or Friction parameters are not correct.

The internal feedforward velocity and acceleration gains are calculated by using the Inertia Ratio and Friction parameters. The feedforward acceleration gain is calculated from the Inertia Ratio parameter and the feedforward velocity gain is calculated from the Friction parameter.

When Feedforwards are enabled, the accuracy of the Inertia Ratio and Friction parameters is very important. If the Inertia Ratio parameter is larger than the actual inertia, the result would be a significant velocity overshoot during ramping. If the Inertia parameter is smaller than the actual inertia, velocity error during ramping will be reduced but not eliminated. If the Friction parameter is greater than the actual friction, it may result in velocity error or instability. If the Friction parameter is less than the actual friction, velocity error will be reduced by not eliminated.

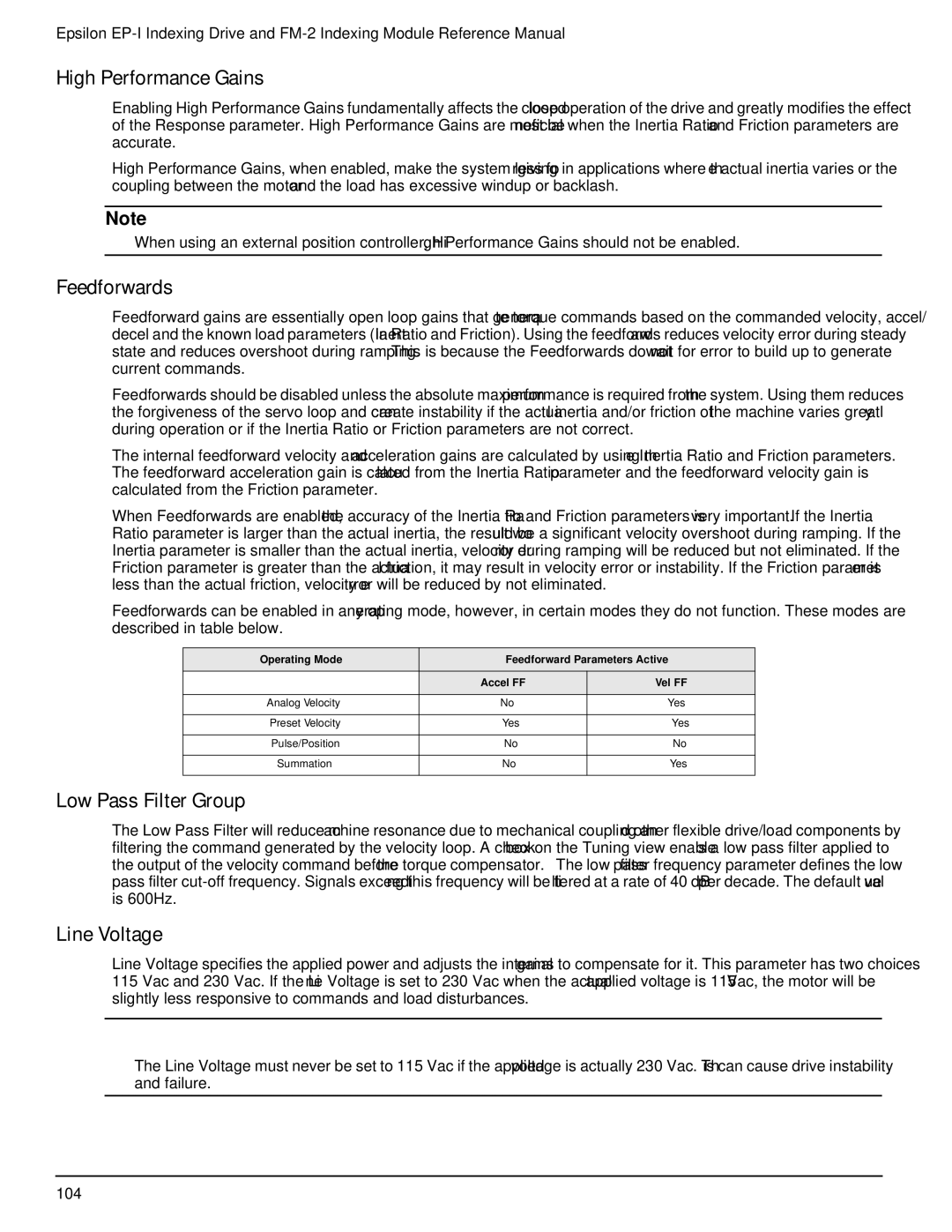

Feedforwards can be enabled in any operating mode, however, in certain modes they do not function. These modes are described in table below.

Operating Mode | Feedforward Parameters Active | |

| Accel FF | Vel FF |

Analog Velocity | No | Yes |

|

|

|

Preset Velocity | Yes | Yes |

|

|

|

Pulse/Position | No | No |

|

|

|

Summation | No | Yes |

|

|

|

Low Pass Filter Group

The Low Pass Filter will reduce machine resonance due to mechanical coupling and other flexible drive/load components by filtering the command generated by the velocity loop. A check box on the Tuning view enables a low pass filter applied to the output of the velocity command before the torque compensator. The low pass filter frequency parameter defines the low pass filter

Line Voltage

Line Voltage specifies the applied power and adjusts the internal gains to compensate for it. This parameter has two choices 115 Vac and 230 Vac. If the Line Voltage is set to 230 Vac when the actual applied voltage is 115 Vac, the motor will be slightly less responsive to commands and load disturbances.

The Line Voltage must never be set to 115 Vac if the applied voltage is actually 230 Vac. This can cause drive instability and failure.

104