User Defined Motors

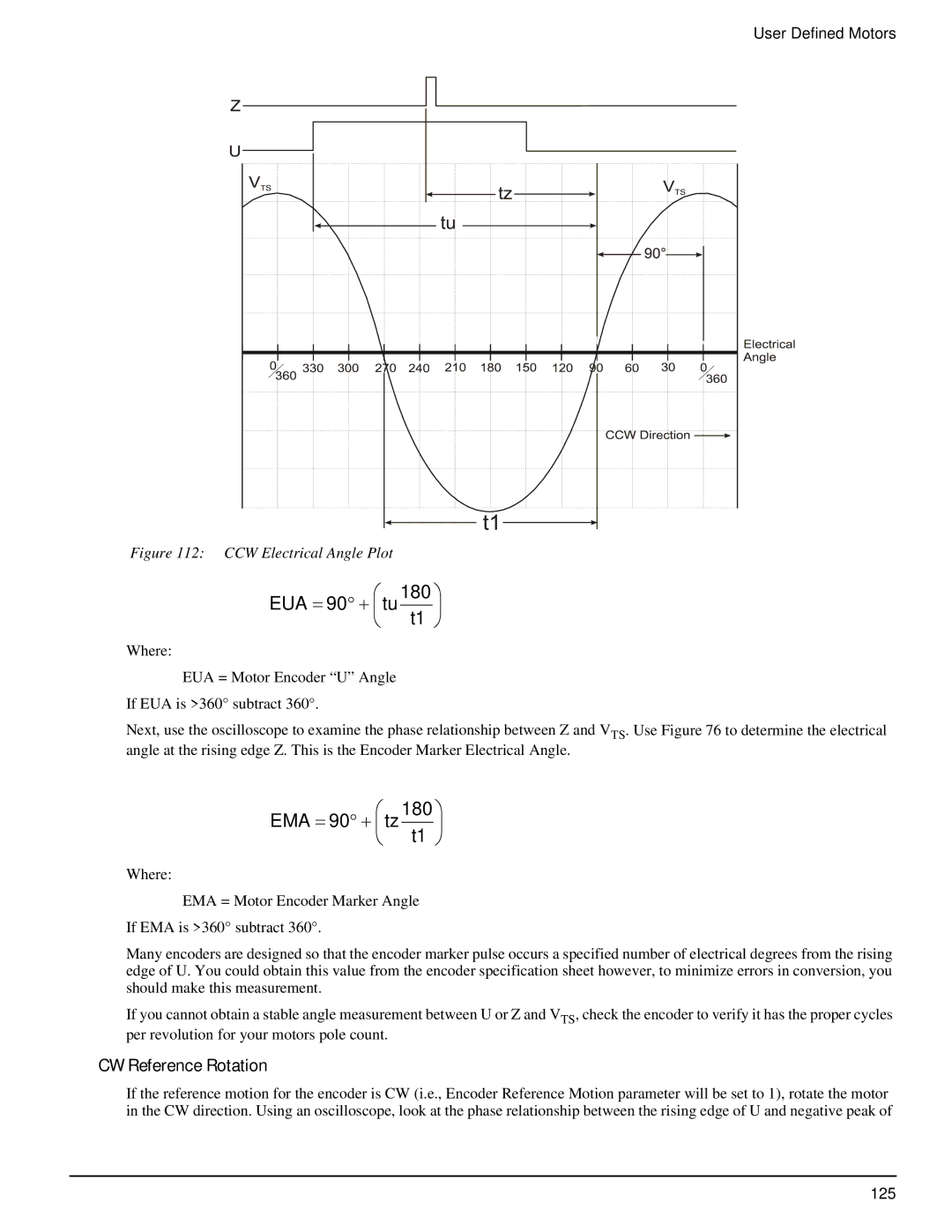

Figure 112: CCW Electrical Angle Plot

⎛ | 180 ⎞ | |

EUA = 90° + ⎜ tu | t1 | ⎟ |

⎝ | ⎠ | |

Where: |

|

|

EUA = Motor Encoder “U” Angle |

|

|

If EUA is >360° subtract 360°. |

|

|

Next, use the oscilloscope to examine the phase relationship between Z and VTS. Use Figure 76 to determine the electrical angle at the rising edge Z. This is the Encoder Marker Electrical Angle.

⎛ | 180 ⎞ | ||

EMA = 90° + ⎜ tz |

| ⎟ | |

t1 | |||

⎝ | ⎠ | ||

Where:

EMA = Motor Encoder Marker Angle If EMA is >360° subtract 360°.

Many encoders are designed so that the encoder marker pulse occurs a specified number of electrical degrees from the rising edge of U. You could obtain this value from the encoder specification sheet however, to minimize errors in conversion, you should make this measurement.

If you cannot obtain a stable angle measurement between U or Z and VTS, check the encoder to verify it has the proper cycles per revolution for your motors pole count.

CW Reference Rotation

If the reference motion for the encoder is CW (i.e., Encoder Reference Motion parameter will be set to 1), rotate the motor in the CW direction. Using an oscilloscope, look at the phase relationship between the rising edge of U and negative peak of

125