Tuning Procedures

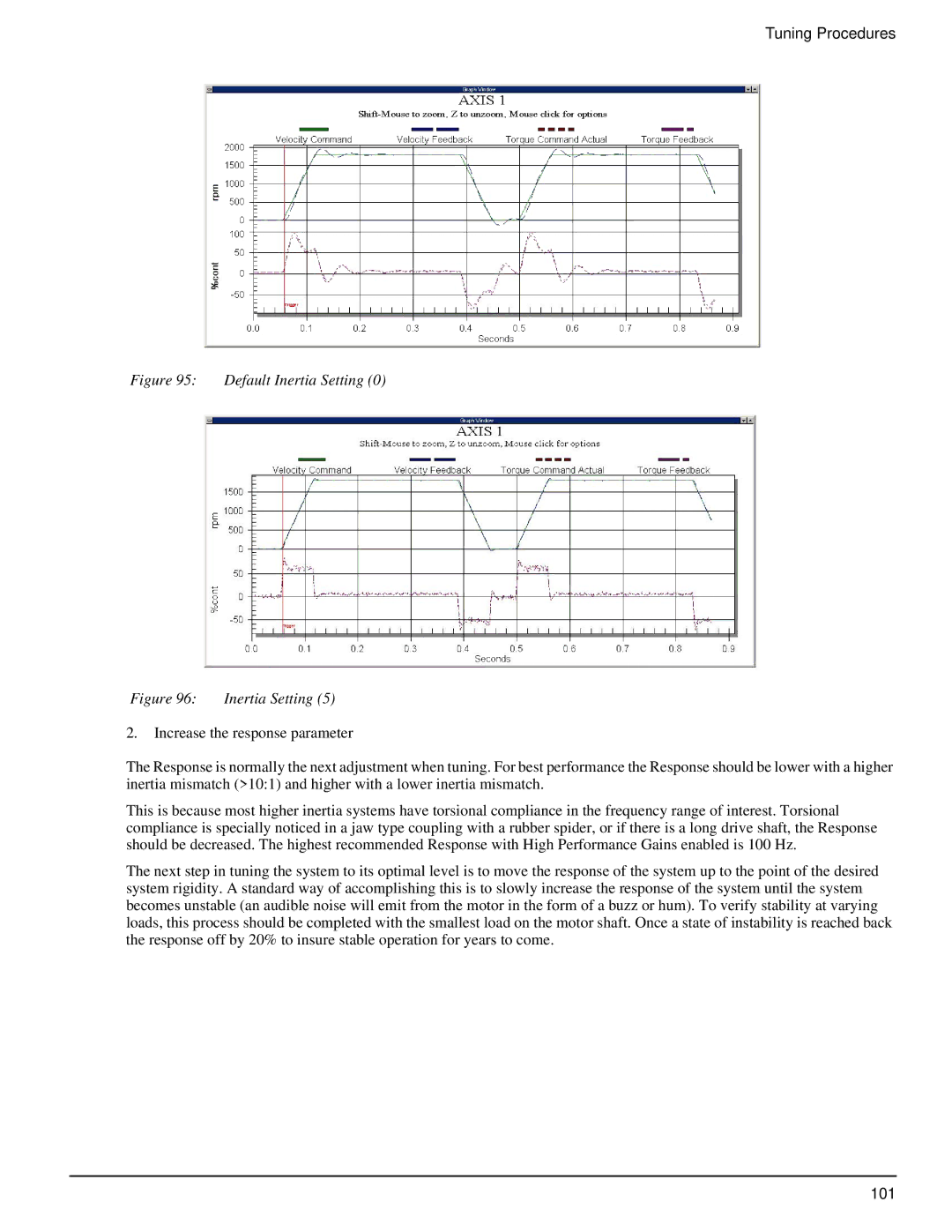

Figure 95: Default Inertia Setting (0)

Figure 96: Inertia Setting (5)

2.Increase the response parameter

The Response is normally the next adjustment when tuning. For best performance the Response should be lower with a higher inertia mismatch (>10:1) and higher with a lower inertia mismatch.

This is because most higher inertia systems have torsional compliance in the frequency range of interest. Torsional compliance is specially noticed in a jaw type coupling with a rubber spider, or if there is a long drive shaft, the Response should be decreased. The highest recommended Response with High Performance Gains enabled is 100 Hz.

The next step in tuning the system to its optimal level is to move the response of the system up to the point of the desired system rigidity. A standard way of accomplishing this is to slowly increase the response of the system until the system becomes unstable (an audible noise will emit from the motor in the form of a buzz or hum). To verify stability at varying loads, this process should be completed with the smallest load on the motor shaft. Once a state of instability is reached back the response off by 20% to insure stable operation for years to come.