GE Fanuc Automation

Cimstar

Cimplicity

Promacro

Cimplicity 90-ADS

Preface

Related Publications

Preface

We Welcome Your Comments and Suggestions

Page

Contents

Contents

O Fault Table Explanations

Section Math Functions

Bit Operation Functions

Table Functions

Control Functions 107

137

Appendix a Instruction Timing

180

173

Table B-7

Introduction

Page

System Operation

Standard Program Sweep

PLC Sweep Summary

PLC Sweep

Calculate sweep time

Sweep Description Time Contribution ms Element

GCM

Sweep Time Calculation

Input Scan

Application Program Logic Scan or Solution

Output Scan

Programmer Communications Window

System Communications Window Models 331 and Higher

Programmer Communications Window Flow Chart

System Communications Window Flow Chart

PCM Communications with the PLC

PCM Communications with the PLC Models 331 and Higher

Standard Program Sweep Variations

Constant Sweep Time Mode

Page

YES

ON/RUN

OFF/STOP

Subroutine Blocks Series 90-30 PLC only

Program Organization and User References/Data

GFK-0467K System Operation

Examples of Using Subroutine Blocks

How Blocks Are Called

Type Description

User References

Retentiveness of Data

Transitions and Overrides

Page

Real

Data Types

Type Name Description Data Format

Byte

Reference Nickname Definition

System Status References

Reference Name Definition

Function Block Structure

Format of Program Function Blocks

MUL

Function Block Parameters

Power Flow In and Out of a Function

Power-Up

Power-Up and Power-Down Sequences

Power-Up Sequence

Flow Chart Terms

Power-Down

Time-of-Day Clock

Clocks and Timers

Elapsed Time Clock

Time-Tick Contacts

Watchdog Timer

Constant Sweep Timer

Privilege Level Description

Passwords

System Security

Type of Lock Description

Privilege Level Change Requests

Locking/Unlocking Subroutines

PLC I/O System

Series 90-30,90-20, and Micro I/O System

Catalog Pub Number Points Description

Model 30 I/O Modules

Input/Output Modules

Catalog Pub Number Description

Default Conditions for Model 30 Output Modules

Diagnostic Data

Data Formats

Catalog Number Description Points

Global Data

Model 20 I/O Modules

Micro PLCs

Section Title Description

Fault Explanation and Correction

Fault Class Examples

Fault Handling

Attribute Description

Fault Tables

Fault Summary

Fault Action Response by CPU

Fault Action

Fault Actions

Side Effect Description

Fault Reference Definitions

Accessing Additional Fault Information

Fault Description

PLC Fault Table Explanations

Loss of, or Missing, Option Module

Fault Actions

Daughterboard

Reset of, Addition of, or Extra, Option Module

System Configuration Mismatch

Program Block Checksum Failure

Low Battery Signal

Option Module Software Failure

Constant Sweep Time Exceeded

Application Fault

Informational

Corrupted User Program on Power-Up

Password Access Failure

No User Program Present

PLC CPU System Software Failure

Corrupted PLC Program Memory

Communications Failure During Store

Diagnostic

O Fault Table Explanations

Addition of I/O Module

Series 90-30/20/Micro Instructions Set

Function

Using Contacts

Type of Contact Display Contact Passes Power to Right

Relay Functions

Types of Coils

Using Coils

Type of Coil Display Power to Coil Result

Negated Coil

Normally Open Contact

Normally Closed Contact

Coil

Negative Transition Coil -↓

Retentive Coil -M

Negated Retentive Coil -/M

Positive Transition Coil -−

SET Coil -S

Reset Coil -R

Links

Retentive Reset Coil -RM

Retentive SET Coil -SM

Continuation Coils ---+ and Contacts +

Abbreviation Function

Timers and Counters

Function Block Data Required for Timers and Counters

15 14 13 12 11 10 9 5 4 3 2 1

Special Note on Certain Bit Operations

Ondtr

Parameter Flow Const None

Parameters

Valid Memory Types

Parameter Description

Const -PV

TMR

Parameters

Do DWL REL

Ofdt

EnableQ

Parameter flow %I %M %T %S %G %R AI %AQ const none

Upctr

Prtcnt

Dnctr

Countp

INT

Const

Abbreviation Function Description

Math Functions

INT

Standard Math Functions ADD, SUB, MUL, DIV

Data Type Description

I0001 Q0001

Function Operation Displays as

Math Functions and Data Types

Alwon

MOD INT, Dint

MOD

Sqrt INT, DINT, Real

I0001 Sqrt

Acos in =

Trig Functions SIN, COS, TAN, ASIN, ACOS, Atan

Enable

Logarithmic/Exponential Functions LOG, LN, EXP, Expt

Expt

Radian Conversion RAD, DEG

RAD

Relational Functions

Function Description

Expanded Description

BINFUL-I2

Word

Range INT, DINT, Word

Parameters

Constant

Range Truth Table Enable State L1 Value L2 Value

Bit Operation Functions

ROL

XOR

SHL

SHR

Or Word

WORD1 WORD2 Result

XOR Word

WORD3

Not Word

CAT -I1 Q-TAC

SHL and SHR Word

LEN

Length -N

ROL and ROR Word

R0001

Btst Word

PICKBIT-BIT

Bset and Bclr Word

SET

POS

Bpos Word

POS Word

If a Miscompare is Found

Mskcmp WORD, Dword

If All Bits in I1 and I2 are the Same

User logic to determine if a miscompare has occurred

I2 %M0017 = %M0033

I2 %M0017 = 606Fh = %M0033 = 000Fh =

Shfr

Data Move Functions

Move

Blkclr

Move BIT, INT, WORD, Real

Parameters

Before using the Move function

Constant value -IN1 Q- output parameter Q

Blkmov INT, WORD, Real

Enable IN1 IN7

Blkclr Word

BLK

Shfr BIT, Word

Parameters

Nxtcyc

Memory Required for a Bit Sequencer

Bitseq BIT

Step

DIR

Nxtseq

Commreq

Command Block

Sysid

Command block has the following structure

REQ

Table Functions

Arraymove INT, DINT, BIT, BYTE, Word

SNX

Const -SNX

00020

Input index -NX NX- output index

Contains the object of the search

I0001 Srch

Conversion Functions

BCD-4 INT

I0017-IN Q-%Q0033

INT BCD-4, Real

Total

Dint Real

R0017-IN Q-%R0001

Real INT, DINT, BCD-4, Word

Alwon INT Real

Word Real

I0002 REAL----------------RANGE

Trun INT, Dint

Real

Control Functions

Call

Doio

END

Input Example

Output Example

Normal Doio Enhanced Doio Module Execution Time

Enhanced do I/O Function for 331 and Later CPUs

SER

Enable Control Block

ParameterOffset Description

ParameterOffset Description

State Description

Status Extra Data

Offset Parameter Description

SER Data Block

SER Notes

GFK-0467K Series 90-30/20/Micro Instructions Set 119

Offset Register Parameter Description Value dec Value hex

GFK-0467K Series 90-30/20/Micro Instructions Set 121

Data Block

Channel Number Channel Contents

END

MCR

Differences Between MCRs and JUMPs

First + Endmcr

Endmcr

Jump

Non-nested Jump Nested Jump

Example of a nested Label

Label

Comment

Svcreq

Service Request Functions

GFK-0467K Series 90-30/20/Micro Instructions Set 133

∙ Disable Constant Sweep mode

Svcreq #1 Change/Read Constant Sweep Timer

Disable Constant Sweep mode Enable Constant Sweep mode

Ovswp

Svcreq #2 Read Window Values

Mode Name Value Description

Q0102

GFK-0467K Series 90-30/20/Micro Instructions Set 139

INT REQ Const -IN

High Byte Low Byte

Svcreq #4 Change System Comm. Window Mode and Timer Value

Word REQ

To Set a New Word Count

Svcreq #6 Change/Read Number of Words to Checksum

To Read the Current Word Count

Word INT

Svcreq #7 Change/Read Time-of-Day Clock

Const -+FNC

To Change/Read Date and Time Using BCD Format

Parameter Block Contents

Page

Svcreq #8 Reset Watchdog Timer

Svcreq #9 Read Sweep Time from Beginning of Sweep

Svcreq #10 Read Folder Name

Svcreq #11 Read PLC ID

Svcreq #12 Read PLC Run State

Svcreq #13 Shut Down Stop PLC

Svcreq #14 Clear Fault Tables

Fault Table Output Format

Svcreq #15 Read Last-Logged Fault Table Entry

PLC Fault Table Output Format

GFK-0467K Series 90-30/20/Micro Instructions Set 157

R0600

GFK-0467K Series 90-30/20/Micro Instructions Set 159

Svcreq #16 Read Elapsed Time Clock

Svcreq #18 Read I/O Override Status

Svcreq #23 Read Master Checksum

Svcreq #26/30 Interrogate I/O

Svcreq #29 Read Elapsed Power Down Time

Read Extra Status Data Function #1

Svcreq #46Fast Backplane Status Access

Location Field Meaning

Write Data Function #2

Read/Write Data Function #3

GFK-0467K Series 90-30/20/Micro Instructions Set 169

Word Const -IN

IND

PID

Parameters. Uses 40 %R words that cannot be shared

PLC

PID Parameter Block

PID Parameters Overview

Register Parameter Low Bit Units Range of Values

PID Parameters Overview

Operation of the PID Instruction

Data Item Description

PID Parameters Details

Bit

Internal Parameters in RefArray

PID Algorithm Selection Pidisa or Pidind and Gains

Independent Term Algorithm Pidind

CV Amplitude and Rate Limits

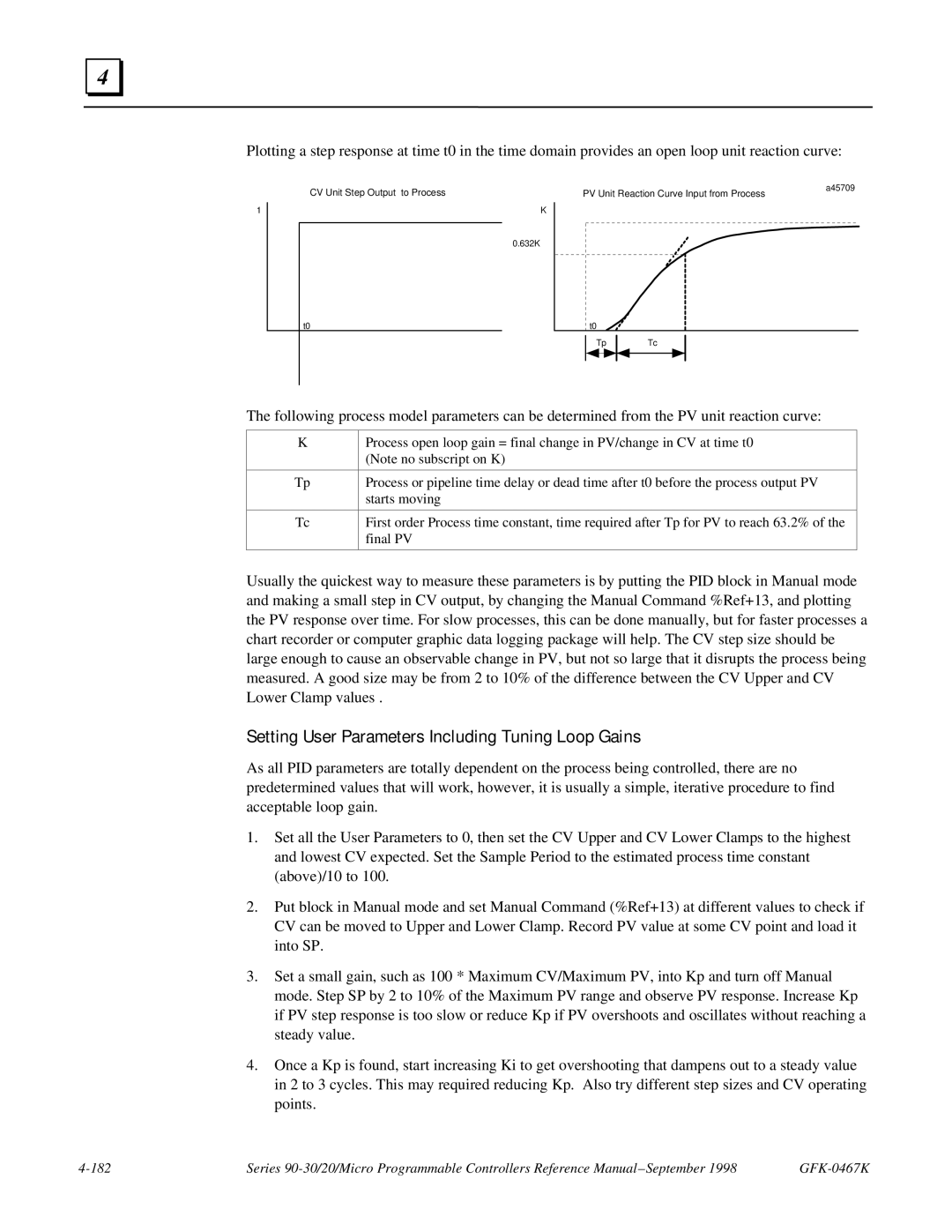

PVs/CVs = Gs = K * e **-Tp s/1 + Tc s

Determining the Process Characteristics

Sample Period and PID Block Scheduling

Setting User Parameters Including Tuning Loop Gains

Setting Loop Gains Ziegler and Nichols Tuning Approach

Sample PID Call

GFK-0467K Series 90-30/20/Micro Instructions Set 185

Execution Time Description

Instruction Timing

340/41 311

Table A-1. Instruction Timing

GFK-0467K Appendix a Instruction Timing

331 340/41

Function Enabled Disabled Increment

Group Function

Disabled

Table A-1 InstructionTiming

End Instruction Service Request #7 Read #7 Set #14

Table A-3. Boolean Execution Speeds

Boolean Execution Speed

Instruction Sizes for 350 and 360 Series CPUs

Table A-2. Instruction Sizes for 350 and 360 Series CPUs

Interpreting Fault Tables

PLC Fault Table

Slot

Long/Short Indicator

Spare

Rack

Table B-1. PLC Fault Groups

PLC Fault Group

Table B-3. Alarm Error Codes for PLC CPU Software Faults

Fault Action

Error Code

Table B-2. PLC Fault Actions

Prgsyntaxerr

Table B-4. Alarm Error Codes for PLC Faults

Comreq

Plciscppcoverflow

Table B-6. PLC Fault Time Stamp

Fault Extra Data

PLC Fault Time Stamp

Table B-5. PLC Fault Data Illegal Boolean Opcode Detected

Fault Table

Table B-8. I/O Reference Address

Fault Address

Table B-7. I/O Fault Table Format Indicator Byte

Reference Address

Point

Fault Group

Table B-10. I/O Fault Groups

Table B-11. I/O Fault Actions

Fault Specific Data

Symbolic Fault Specific Data

Fault Actions for Specific Faults

Table B-13. I/O Fault Time Stamp

Fault Time Stamp

Instruction Mnemonics

Function Instruction Mnemonic Group

GFK-0467K Appendix C Instruction Mnemonics

Key Sequence Description

Page

Print side 1 of GFJ-055C on this

Print side 2 of GFJ-055C on this

Entered Displayed Description

Floating-Point Numbers

Page

Internal Format of Floating-Point Numbers

Exponent e Mantissa f Value of Floating Point Number

Values of Floating-Point Numbers

Invalid Entry Explanation

Entering and Displaying Floating-Point Numbers

Entered Displayed

Realindef

Errors in Floating-Point Numbers and Operations

Posinf

Neginf

General Case of Power Flow for Floating-Point Operations

Operation Input Output Powerflow

Editlock

Index

Commreq

Index

EXP Exponential functions

Greater than function Greater than or equal function

Not equal function

Real

Signed integer

Arraymove

Sweep time calculation Sweep, PLC

Viewlock