2 |

Sweep Time Calculation

Table

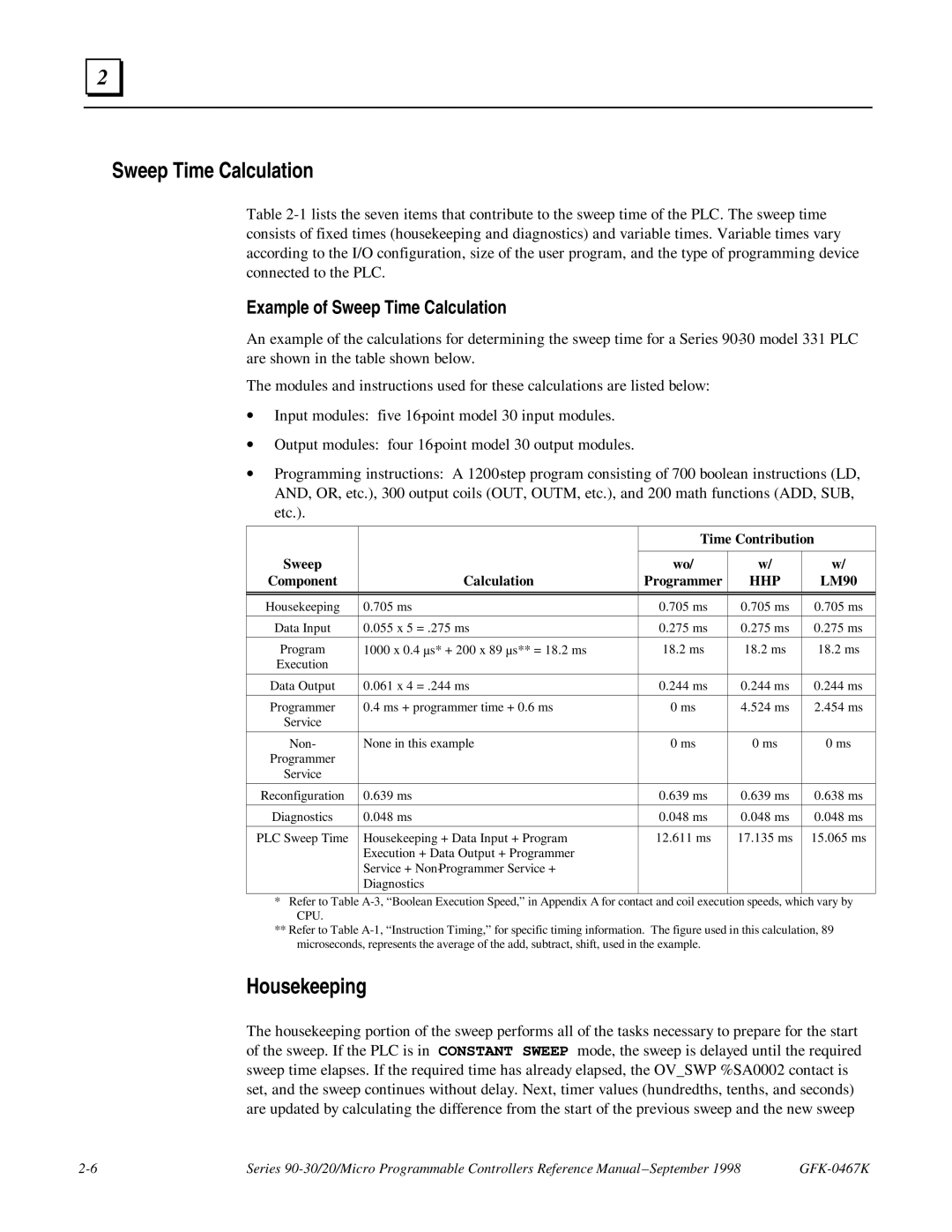

Example of Sweep Time Calculation

An example of the calculations for determining the sweep time for a Series

The modules and instructions used for these calculations are listed below:

∙Input modules: five

∙Output modules: four

∙Programming instructions: A

|

| Time Contribution | ||

|

|

|

|

|

Sweep |

| wo/ | w/ | w/ |

Component | Calculation | Programmer | HHP | LM90 |

|

|

|

|

|

|

|

|

|

|

Housekeeping | 0.705 ms | 0.705 ms | 0.705 ms | 0.705 ms |

|

|

|

|

|

Data Input | 0.055 x 5 = .275 ms | 0.275 ms | 0.275 ms | 0.275 ms |

|

|

|

|

|

Program | 1000 x 0.4 µ s* + 200 x 89 µ s** = 18.2 ms | 18.2 ms | 18.2 ms | 18.2 ms |

Execution |

|

|

|

|

|

|

|

|

|

Data Output | 0.061 x 4 = .244 ms | 0.244 ms | 0.244 ms | 0.244 ms |

|

|

|

|

|

Programmer | 0.4 ms + programmer time + 0.6 ms | 0 ms | 4.524 ms | 2.454 ms |

Service |

|

|

|

|

|

|

|

|

|

Non- | None in this example | 0 ms | 0 ms | 0 ms |

Programmer |

|

|

|

|

Service |

|

|

|

|

|

|

|

|

|

Reconfiguration | 0.639 ms | 0.639 ms | 0.639 ms | 0.638 ms |

|

|

|

|

|

Diagnostics | 0.048 ms | 0.048 ms | 0.048 ms | 0.048 ms |

|

|

|

|

|

PLC Sweep Time | Housekeeping + Data Input + Program | 12.611 ms | 17.135 ms | 15.065 ms |

| Execution + Data Output + Programmer |

|

|

|

| Service + |

|

|

|

| Diagnostics |

|

|

|

|

|

|

|

|

*Refer to Table

**Refer to Table

Housekeeping

The housekeeping portion of the sweep performs all of the tasks necessary to prepare for the start of the sweep. If the PLC is in CONSTANT SWEEP mode, the sweep is delayed until the required sweep time elapses. If the required time has already elapsed, the OV_SWP %SA0002 contact is set, and the sweep continues without delay. Next, timer values (hundredths, tenths, and seconds) are updated by calculating the difference from the start of the previous sweep and the new sweep

Series |