HP LaserJet P3005 Series printers

Page

HP LaserJet P3005 Series printers

Safety information

Copyright information

Trademark credits

Table of contents

Maintenance

Gear assembly

Service approach

Paper feed guide assembly

Reinstallation notes for the gear assembly

Troubleshooting

Order through service or support providers

Print-quality checklist

Wiring diagrams

Paper-handling accessories

Appendix a Specifications

EMI statement Korea

Power cord statement Japan

Vcci statement Japan

Laser statement for Finland

Enww

Alphabetical parts list

Diagnostics menu

Tray 2 pickup assembly

10 Numerical parts list

Xii

Model and serial numbers Systems overview

Print engine general structure

Jam-detection sensors

ECU wiring

Grounding-spring locations

Jetdirect

197

Xvi

Chapter contents

Device information

Device configurations

P3005dn

Features

Feature Description

Accessibility

Supplies

Walkaround

Device parts

Interface ports

Model name Model number

Control-panel layout

Number Button or light

Function

Select

Device software

Minimum system requirements

Supported operating systems

Software for Windows computers

HP Web Jetadmin

Supported printer drivers

HP Easy Printer Care software

Software for Macintosh computers

Other software

Embedded Web server

Uninstall software

Remove software from Windows operating systems

Remove software from Macintosh operating systems

Media specifications

Select print media

1Supported media sizes

Media size Dimensions Weight and thickness

Supported media sizes

2Automatic 2-sided printing

3Tray 1 media types

Type Dimensions

Supported media types

4Tray 2 and tray 3 media types

Paper to avoid

Installation and configuration

Location specifications

Site preparation

Operating environment

Load input trays

Load tray 1 multipurpose tray

Enww

Load tray 2 and optional tray

Enww

Install supplies

Supply replacement guidelines

Change the print cartridge

Enww

Enww

Install accessories

Install memory

Install device memory

Install accessories

Enww

Check Dimm installation

Verify that Dimm is installed correctly

Enable memory for Windows

Install an HP Jetdirect print server card

Use HP Jetdirect print server cards

Remove an HP Jetdirect print server card

Enww

Maintenance

Supplies life

Approximate print-cartridge replacement intervals

Manage supplies

Manage the print cartridge

Print-cartridge authentication

HP fraud hotline and Web site

Clean the paper path

Clean the device

Clean the exterior

Clean spilled toner

Create and use the cleaning

Description How to print

Management tools

Use information pages

File directory

Use the HP Easy Printer Care software

Open the HP Easy Printer Care software

PCL or PS font list

HP Easy Printer Care software sections

SectionOptions

Embedded Web server sections

Open the embedded Web server by using a network connection

Use the embedded Web server

Tab or section Options

Or Sleep mode on

Settings tab

Tab or section

Use HP Web Jetadmin software

Use the HP Printer Utility for Macintosh

Networking tab

HP Printer Utility features

Open the HP Printer Utility

Theory of operation

Basic operation

Formatter

Engine control unit ECU

Formation roller

3Engine control system circuit diagram Theory of operation

ECU

Pickup/feed/delivery system

Laser/scanner system

6Laser/scanner system

Image-formation system

8Image-formation system Theory of operation

Primary charging

Laser beam exposure

Developing

Fusing

Transfer

Separation

Drum cleaning

13 Fusing

Internal components

15Cross-section of device

Internal components

1Operation sequences

2Power-on sequence

Timing

Name Timing Purpose

16Operational sequences

Timing diagram

Print cartridge memory system

Write

Enww

Removal and replacement

Separation pad

Electrostatic discharge

Removal and replacement strategy

Overview

Required tools

Types of screws

Illustration Description Size Part number Use

Service approach

Before performing service

Pre-service procedures

After performing service

Parts removal order

Covers

Right-side cover

Left-side cover

Enww

Back cover

Cover

Top, right cover

6Removing the I/O cover Lift the cover off of the device

Top cover

Front, right cover

8Removing the top cover Lift the cover off of the device

9Removing the front, right cover 1 Removal and replacement

Enww

Control panel

12Reinstalling the control panel

13Removing the formatter 1 Removal and replacement

Formatter

14Removing the formatter 2

15Removing the formatter 3 Removal and replacement

Fuser

Back cover see Back cover on Cover see I/O cover on

17Removing the fuser 2 Removal and replacement

Enww

19Removing the laser/scanner 1 Removal and replacement

Laser/scanner

Laser/scanner

21Removing the ECU 1 Removal and replacement

Engine control unit ECU

22Removing the ECU 2

23Removing the ECU 3 Removal and replacement

24Removing the ECU 4

25Removing the ECU 5 Removal and replacement

26Removing the ECU 6

27Removing the ECU 7 Removal and replacement

Enww

Access plate

High-voltage power supply

31Removing the power supply 1

Enww

33Removing the power supply 3

Enww

35Removing the power supply 5

Enww

37Reinstalling the oblique-roller assembly

Paper feed guide assembly

Paper feed guide assembly

Main motor

40Removing the main motor 2

Gear assembly

41Removing the gear assembly 1 Removal and replacement

Remove four screws callout 3 from the gear-assembly plate

Reinstallation notes for the gear assembly

43Reinstalling the gear assembly Removal and replacement

Tray 1 solenoid

Tray 2 solenoid

Label reader memory tag

46Removing the e-label reader 1

Enww

Face-down-roller shaft

48Removing the face-down-roller shaft 1

Enww

Cartridge door

50Removing the cartridge door 1

51Removing the cartridge door 2 Removal and replacement

52Removing the cartridge door 3

Transfer roller

Registration assembly

54Removing the registration assembly 1

Enww

Remove four screws callout

Tray 1 pickup roller

Tray 2 pickup roller

Enww

Separation pad

Enww

Troubleshooting

Troubleshooting process

Basic troubleshooting

Resolve control-panel messages

Control-panel messages

Control-panel message types

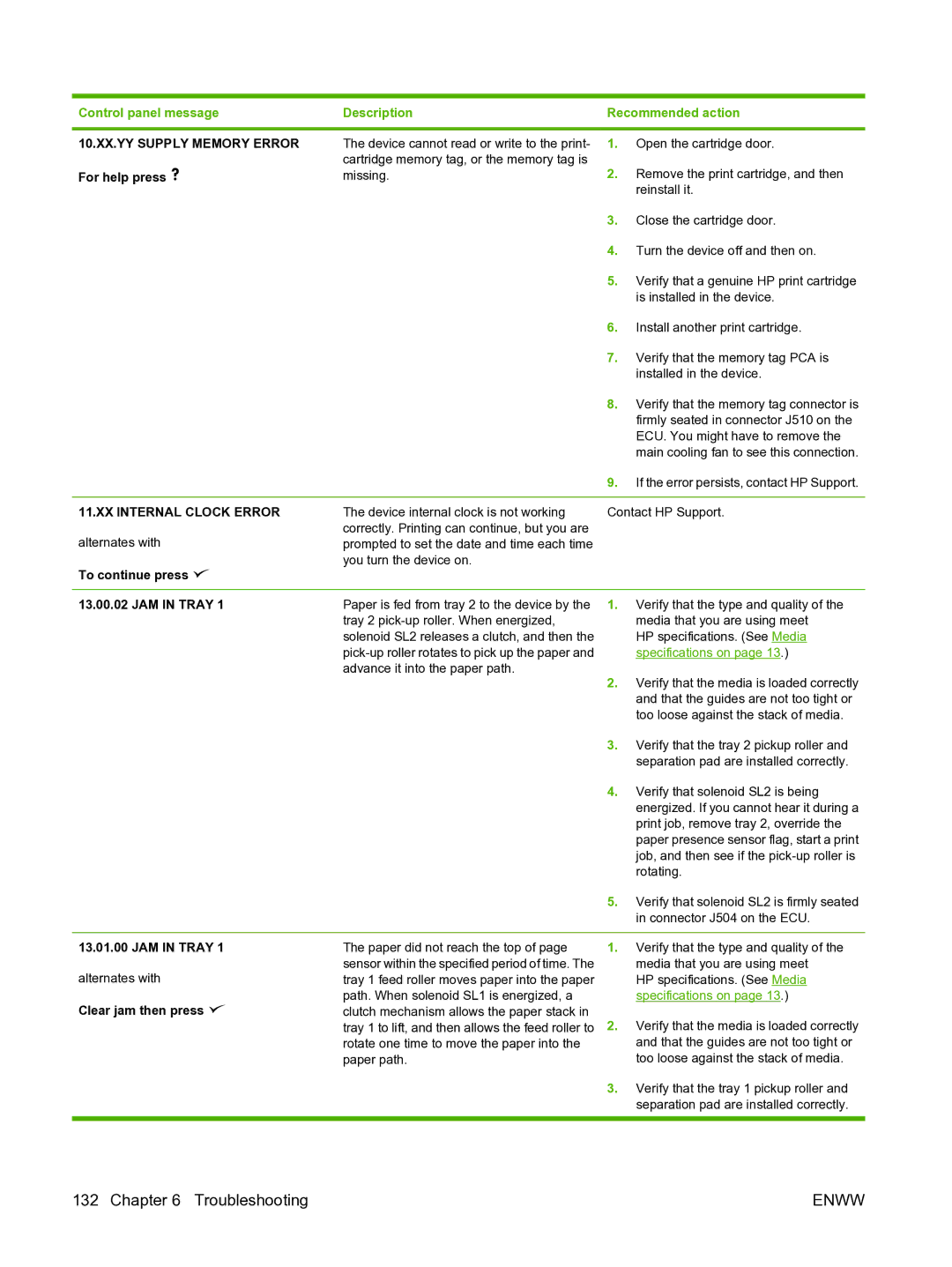

Control panel message Description Recommended action

10.XX.YY Supply Memory Error

XX Internal Clock Error

JAM Inside Rear Door

JAM Inside TOP Cover

JAM Inside Front Door

13.XX.YY Fuser JAM Inside TOP

13.XX.YY JAM in Tray

13.XX.YY JAM Inside Duplexer

Insufficient Memory

13.XX.YY JAM Inside Rear Door

13.XX.YY JAM Inside TOP Cover

TOO Complex

Parallel I/O Buffer Overflow

EIO X Buffer Overflow

Embedded I/O Buffer Overflow

Serial I/O Buffer Overflow

Embedded I/O BAD Transmission

Error

Xxxxx Error

Unexpected Size in Tray

Fuser Error

XY Error

To continue turn off then on

55.XX.YY DC Controller Error

Alternates with Formatter To continue turn off then on

No System

Permanent Storage Full

Storage Error Settings

8X.YYYY EIO Error

Permanent Storage Write Fail

On Tray

8X.YYYY Embedded Jetdirect

Action not Currently Available

Custom Chosen Personality not

Close TOP Cover

Code CRC Error

Install Black Cartridge

Data Received

Load Tray X Type Size

Insufficient Memory to Load

FONTS/DATA

Load Tray 1 Plain Paper

MEM Test Failure Replace Dimm

NON HP Supply Installed

Manually Feed Output Stack

NON HP Supply in USE

RAM Disk File System is Full

RFU Load Error

RAM Disk File Operation Failed

RAM Disk is Write Protected

Tray XX Open

USB Accessory Error

Tray XX Empty Type Size

Tray XX Open or Empty

USB Storage X Removed

USB Storage File System is Full

USB Storage is Write Protected

USE Tray X Type Size

Avoid jams

Cause Solution

Clear jams

1Common causes of jams

Typical jam locations

Jam detection

1Jam-detection sensors

Clear jams from the input-tray areas

Jam type Description

Enww

Clear jams from the print-cartridge area

Clear jams from the output-bin areas

Clear jams from the optional duplexer

Enww

Communications checks

Interface troubleshooting

EIO troubleshooting

Computer direct connect parallel test

Network printing problems

Jetdirect

Packet Size

Service mode functions

Cold reset

Nvram initialization

Skip disk-load

Service menu service PIN codes

Hard-disk initialization

Self test

Service ID

Restoring the service ID

Convert the service ID to an actual date

2Diagnostics menu

Troubleshooting tools

Diagnostics menu

Control-panel menus

Test pages

Engine-test

Formatter test

Image defect ruler

Upgrade the firmware

Use FTP to upgrade the firmware on a network connection

Determine the current firmware version

Use HP Web Jetadmin to upgrade the firmware

Use MS-DOS commands to upgrade the firmware

\YOURSERVER\YOURCOMPUTER

Upgrade the HP Jetdirect firmware

Device does not pull media from a tray Cause Solution

Troubleshoot general printing problems

Device selects media from the wrong tray CauseSolution

Paper curls when it exits the device Cause Solution

Print job prints on both sides of the paper Cause Solution

Pages print, but are totally blank Cause Solution

Messages and see Control-panel messages on

Pages are wrinkled or folded

Troubleshoot media handling problems

Multiple pages feed

Pages are skewed

Assembly on

Troubleshoot print-quality problems

Print-quality checklist

Image-defect examples

AaBbCc

Light print partial

AaBbCc

Light print entire

Specks

Dropouts

Lines

Gray background

Toner smear

Loose toner

Repeating defects

Repeating image

Misformed characters

Skew

Curl or wave

Wrinkles or creases

Vertical white lines

Tire tracks

White spots on black

Scattered lines

Blurred print

Random image repetition

Diagrams

Device component locations

Main assemblies

Main parts

Main parts

Sensors and switches

6Sensors and switches

Motors, fans, and solenoids

7Motors, fans, and solenoids

Wiring diagrams

PCAs

3 4 12 11

10Circuit diagram 1 196 Chapter Troubleshooting

Circuit diagram 2

Enww

Parts and diagrams

Order directly from HP

Order parts, accessories, and supplies

Order through service or support providers

Order directly through the HP Easy Printer Care software

Print cartridge

Paper-handling accessories

Part numbers

Memory

Cables and interfaces

Enww

Covers

Covers

Description Part number Qty

2Internal components 1 Parts and diagrams

2Internal components 1

Enww

Enww

3Internal components 2 Parts and diagrams

3Internal components 2

502 Pin, dowel XD3-2120-122 503 Ring, E XD2-1200-802

Enww

4Internal components 3 Parts and diagrams

4Internal components 3

5Internal components 4 Parts and diagrams

5Internal components 4

6Internal components 5 Parts and diagrams

6Internal components 5

7Internal components 6

7Internal components 6

Tray 2 pickup assembly

8Tray 2 pickup assembly Parts and diagrams

8Tray 2 pickup assembly

Alphabetical parts list

9Alphabetical parts list

Connector, snap tight, bk VS1-7177-004

Film, fuser drive side plate RC2-0649-000

Internal components 4

Holder, switch link RC2-0634-000

Motor, DC M1, main RK2-1488-000

Registration assembly RM1-3715-000

Sensor-flag assembly RM1-3769-000

Spring, torsion RU5-2386-000

Numerical parts list

10Numerical parts list

Part number Description

RC1-4061-000 Spring, torsion

RC2-0468-000 Cushion, right lower

RC2-0612-000 Cover, engine controller

RC2-0705-000 Lever, drive release

RM1-3716-000 Multipurpose paper pick-up roller assembly

RM1-4040-000 Top sensor PCA PS901

RU5-2386-000 Spring, torsion

XA9-1503-000 Screw, tap, M3x6

Enww

Specifications

Device model Height Depth Width Weight

Physical specifications

Table A-1Device dimensions

Device model Height Depth Width

Table A-4Power consumption average, in watts

Electrical specifications

Table A-3Power requirements

Specification Volt models

Operating environment

Acoustic specifications

Table A-5Sound power and pressure level

Table A-6Necessary conditions

Service and support

Hewlett-Packard limited warranty statement

Customer self repair warranty service

Print cartridge limited warranty statement

Online Services

HP service agreements

HP Customer Care

HP Easy Printer Care software

HP support and information for Macintosh computers

Next-day on-site service

HP maintenance agreements

On-site service agreements

Weekly volume on-site service

Extended warranty

Enww

Regulatory information

FCC regulations

Environmental product stewardship program

Material restrictions

HP print supplies returns and recycling program information

Paper

HP LaserJet P3005 device

Material Safety Data Sheet Msds For more information

Enww

Declaration of conformity

Declaration of Conformity

Safety statements

Laser safety

Canadian DOC regulations

Laser statement for Finland

Luokan 1 laserlaite

Enww

Index

ECU

Enww

Msds

RFU

Enww

See also trays

Trays status

Enww

Page

Q7812-90910