Variable Capacity Control of Gas Heat Mode (G71MPP and SLP98V)

The thermostat includes a feature that provides variable capacity control of the gas heat mode. The purpose of variable capacity control is to keep the room temperature at, or near, the desired setpoint with minimum system cycling. The thermostat bases its

using the following inputs:

SRoom temperature,

SHistory of cycle times (how long does it typically take to bring the room temperature to the desired setpoint),

STarget setpoint, and

SDifferential temperature settings between 1st − 4th stage.

The thermostat uses this information to vary the heating capacity to efficient- ly satisfy the heating demand. The full range of the furnace heating capacity (low end is a percent of the 1st stage capacity; high range is 100% of full capacity) is used. When in variable capacity gas heat mode, the furnace op- eration includes longer run times at lower heat stages.

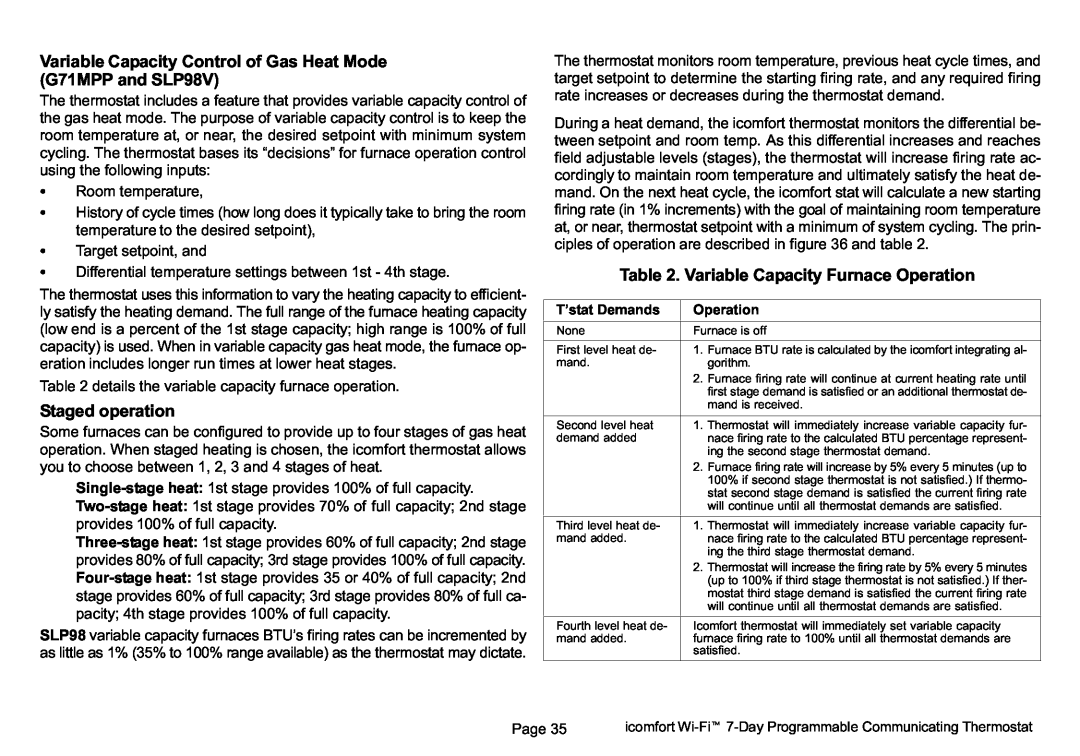

Table 2 details the variable capacity furnace operation.

Staged operation

Some furnaces can be configured to provide up to four stages of gas heat operation. When staged heating is chosen, the icomfort thermostat allows you to choose between 1, 2, 3 and 4 stages of heat.

Single−stage heat: 1st stage provides 100% of full capacity.

Two−stage heat: 1st stage provides 70% of full capacity; 2nd stage provides 100% of full capacity.

Three−stage heat: 1st stage provides 60% of full capacity; 2nd stage provides 80% of full capacity; 3rd stage provides 100% of full capacity. Four−stage heat: 1st stage provides 35 or 40% of full capacity; 2nd stage provides 60% of full capacity; 3rd stage provides 80% of full ca- pacity; 4th stage provides 100% of full capacity.

SLP98 variable capacity furnaces BTU’s firing rates can be incremented by as little as 1% (35% to 100% range available) as the thermostat may dictate.

The thermostat monitors room temperature, previous heat cycle times, and target setpoint to determine the starting firing rate, and any required firing rate increases or decreases during the thermostat demand.

During a heat demand, the icomfort thermostat monitors the differential be- tween setpoint and room temp. As this differential increases and reaches field adjustable levels (stages), the thermostat will increase firing rate ac- cordingly to maintain room temperature and ultimately satisfy the heat de- mand. On the next heat cycle, the icomfort stat will calculate a new starting firing rate (in 1% increments) with the goal of maintaining room temperature at, or near, thermostat setpoint with a minimum of system cycling. The prin- ciples of operation are described in figure 36 and table 2.

Table 2. Variable Capacity Furnace Operation

T’stat Demands | Operation | |

|

| |

None | Furnace is off | |

|

|

|

First level heat de- | 1. | Furnace BTU rate is calculated by the icomfort integrating al- |

mand. |

| gorithm. |

| 2. | Furnace firing rate will continue at current heating rate until |

|

| first stage demand is satisfied or an additional thermostat de- |

|

| mand is received. |

|

|

|

Second level heat | 1. | Thermostat will immediately increase variable capacity fur- |

demand added |

| nace firing rate to the calculated BTU percentage represent- |

|

| ing the second stage thermostat demand. |

| 2. | Furnace firing rate will increase by 5% every 5 minutes (up to |

|

| 100% if second stage thermostat is not satisfied.) If thermo- |

|

| stat second stage demand is satisfied the current firing rate |

|

| will continue until all thermostat demands are satisfied. |

|

|

|

Third level heat de- | 1. | Thermostat will immediately increase variable capacity fur- |

mand added. |

| nace firing rate to the calculated BTU percentage represent- |

|

| ing the third stage thermostat demand. |

| 2. | Thermostat will increase the firing rate by 5% every 5 minutes |

|

| (up to 100% if third stage thermostat is not satisfied.) If ther- |

|

| mostat third stage demand is satisfied the current firing rate |

|

| will continue until all thermostat demands are satisfied. |

|

| |

Fourth level heat de- | Icomfort thermostat will immediately set variable capacity | |

mand added. | furnace firing rate to 100% until all thermostat demands are | |

| satisfied. | |

|

|

|

Page 35 | icomfort |