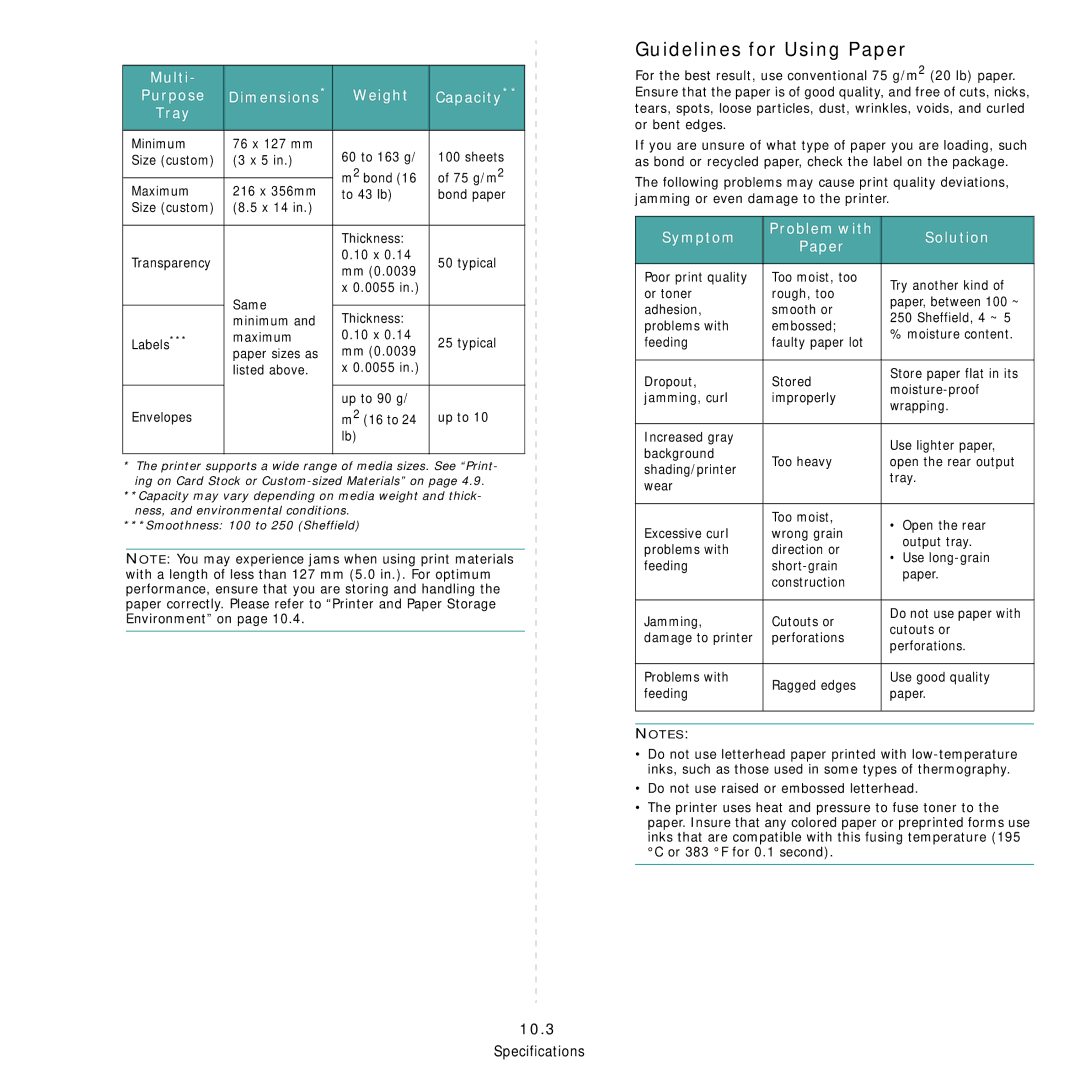

Multi- | Dimensions* |

| Capacity** | |

Purpose | Weight | |||

Tray |

|

|

| |

|

|

|

| |

Minimum | 76 x 127 mm | 60 to 163 g/ | 100 sheets | |

Size (custom) | (3 x 5 in.) | |||

|

| m2 bond (16 | of 75 g/m2 | |

Maximum | 216 x 356mm | |||

to 43 lb) | bond paper | |||

Size (custom) | (8.5 x 14 in.) |

|

| |

|

|

|

| |

|

| Thickness: |

| |

Transparency |

| 0.10 x 0.14 | 50 typical | |

| mm (0.0039 | |||

|

|

| ||

|

| x 0.0055 in.) |

| |

| Same |

|

| |

| Thickness: |

| ||

| minimum and |

| ||

Labels*** | maximum | 0.10 x 0.14 | 25 typical | |

paper sizes as | mm (0.0039 | |||

| listed above. | x 0.0055 in.) |

| |

|

|

|

| |

|

| up to 90 g/ |

| |

Envelopes |

| m2 (16 to 24 | up to 10 | |

|

| lb) |

| |

|

|

|

|

* The printer supports a wide range of media sizes. See “Print- ing on Card Stock or

**Capacity may vary depending on media weight and thick- ness, and environmental conditions.

***Smoothness: 100 to 250 (Sheffield)

NOTE: You may experience jams when using print materials with a length of less than 127 mm (5.0 in.). For optimum performance, ensure that you are storing and handling the paper correctly. Please refer to “Printer and Paper Storage Environment” on page 10.4.

Guidelines for Using Paper

For the best result, use conventional 75 g/m2 (20 lb) paper. Ensure that the paper is of good quality, and free of cuts, nicks, tears, spots, loose particles, dust, wrinkles, voids, and curled or bent edges.

If you are unsure of what type of paper you are loading, such as bond or recycled paper, check the label on the package.

The following problems may cause print quality deviations, jamming or even damage to the printer.

Symptom | Problem with | Solution | |

Paper | |||

|

| ||

|

|

| |

Poor print quality | Too moist, too | Try another kind of | |

or toner | rough, too | ||

paper, between 100 ~ | |||

adhesion, | smooth or | ||

250 Sheffield, 4 ~ 5 | |||

problems with | embossed; | ||

% moisture content. | |||

feeding | faulty paper lot | ||

| |||

|

|

| |

Dropout, | Stored | Store paper flat in its | |

jamming, curl | improperly | ||

wrapping. | |||

|

| ||

|

|

| |

Increased gray |

| Use lighter paper, | |

background |

| ||

Too heavy | open the rear output | ||

shading/printer | |||

| tray. | ||

wear |

| ||

|

| ||

|

|

| |

| Too moist, | • Open the rear | |

Excessive curl | wrong grain | ||

output tray. | |||

problems with | direction or | ||

• Use | |||

feeding | |||

paper. | |||

| construction | ||

|

| ||

|

|

| |

Jamming, | Cutouts or | Do not use paper with | |

cutouts or | |||

damage to printer | perforations | ||

perforations. | |||

|

| ||

|

|

| |

Problems with | Ragged edges | Use good quality | |

feeding | paper. | ||

| |||

|

|

| |

|

|

|

NOTES:

•Do not use letterhead paper printed with

•Do not use raised or embossed letterhead.

•The printer uses heat and pressure to fuse toner to the paper. Insure that any colored paper or preprinted forms use inks that are compatible with this fusing temperature (195 °C or 383 °F for 0.1 second).

10.3

Specifications