Configuring the motor 5.2 Example(s)

transitional phases between acceleration/deceleration and the resulting angle changes are not taken into account.

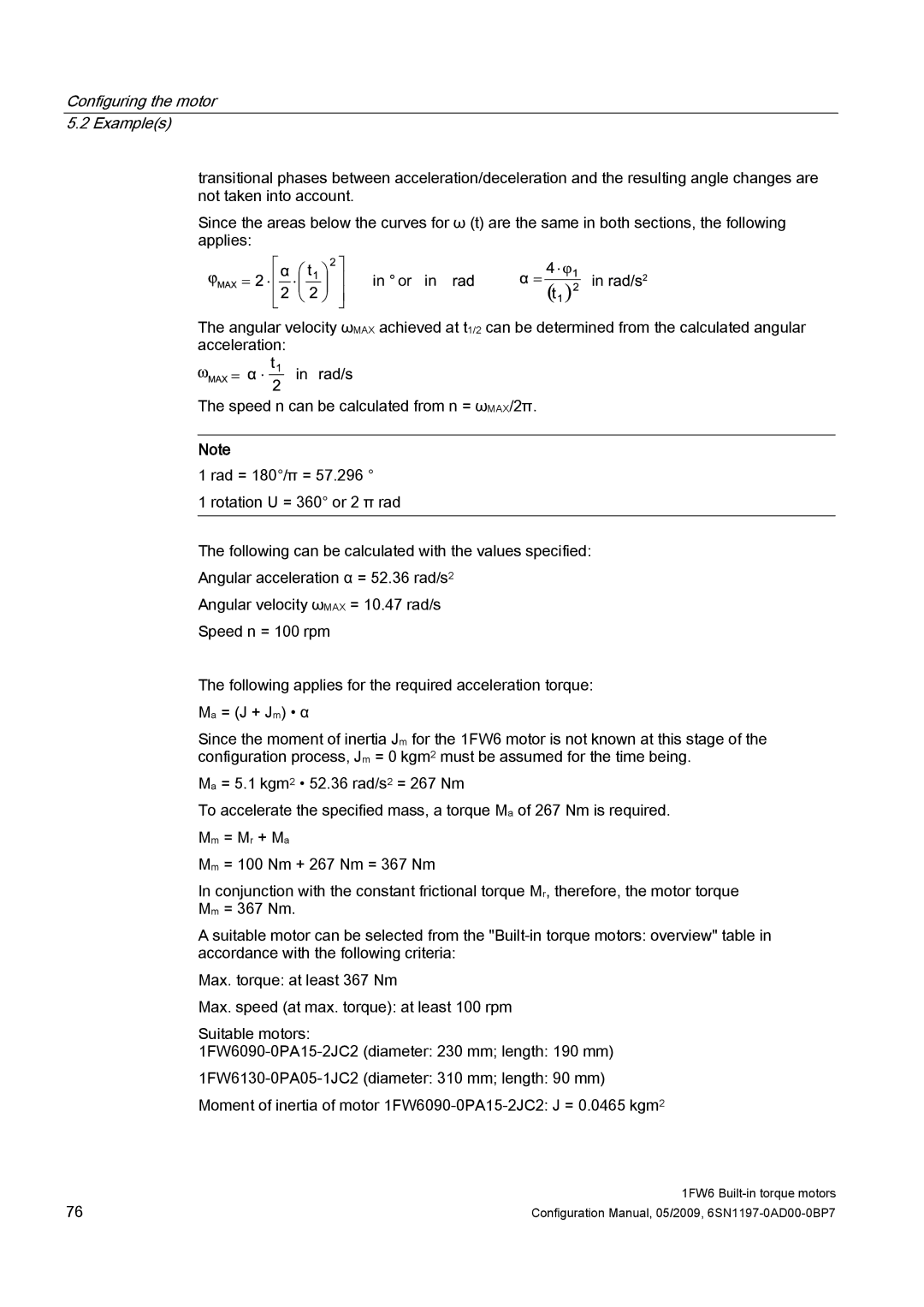

Since the areas below the curves for ω (t) are the same in both sections, the following applies:

LQRULQ

LQ

LQ

The angular velocity ωMAX achieved at t1/2 can be determined from the calculated angular acceleration:

LQ

The speed n can be calculated from n = ωMAX/2π.

Note

1 rad = 180°/π = 57.296 °

1 rotation U = 360° or 2 π rad

The following can be calculated with the values specified:

Angular acceleration α = 52.36 rad/s2

Angular velocity ωMAX = 10.47 rad/s

Speed n = 100 rpm

The following applies for the required acceleration torque: Ma = (J + Jm) • α

Since the moment of inertia Jm for the 1FW6 motor is not known at this stage of the configuration process, Jm = 0 kgm2 must be assumed for the time being.

Ma = 5.1 kgm2 • 52.36 rad/s2 = 267 Nm

To accelerate the specified mass, a torque Ma of 267 Nm is required. Mm = Mr + Ma

Mm = 100 Nm + 267 Nm = 367 Nm

In conjunction with the constant frictional torque Mr, therefore, the motor torque Mm = 367 Nm.

A suitable motor can be selected from the

Max. torque: at least 367 Nm

Max. speed (at max. torque): at least 100 rpm

Suitable motors:

Moment of inertia of motor

76 | 1FW6 |

Configuration Manual, 05/2009, |