Maintenance, Service, and Troubleshooting | Teledyne API Ultrafine Particle Monitor - Model 651 |

instrument Flow Constant status value on the ADDITIONAL STATUS screen.

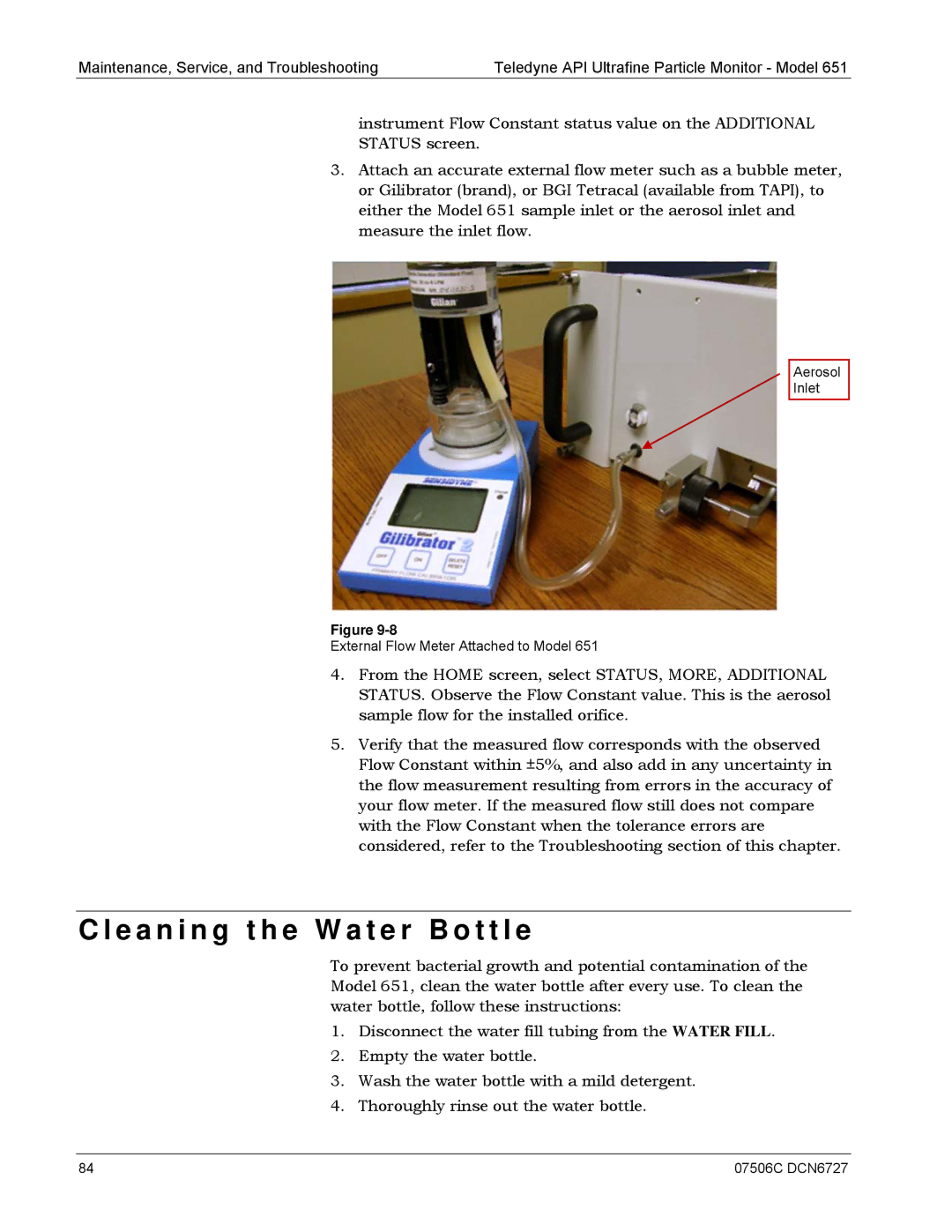

3.Attach an accurate external flow meter such as a bubble meter, or Gilibrator (brand), or BGI Tetracal (available from TAPI), to either the Model 651 sample inlet or the aerosol inlet and measure the inlet flow.

Aerosol

Inlet

Figure

External Flow Meter Attached to Model 651

4.From the HOME screen, select STATUS, MORE, ADDITIONAL STATUS. Observe the Flow Constant value. This is the aerosol sample flow for the installed orifice.

5.Verify that the measured flow corresponds with the observed Flow Constant within ±5%, and also add in any uncertainty in the flow measurement resulting from errors in the accuracy of your flow meter. If the measured flow still does not compare with the Flow Constant when the tolerance errors are considered, refer to the Troubleshooting section of this chapter.

C l e a n i n g t h e W a t e r B o t t l e

To prevent bacterial growth and potential contamination of the Model 651, clean the water bottle after every use. To clean the water bottle, follow these instructions:

1.Disconnect the water fill tubing from the WATER FILL.

2.Empty the water bottle.

3.Wash the water bottle with a mild detergent.

4.Thoroughly rinse out the water bottle.

84 | 07506C DCN6727 |