Maintenance, Service, and TroubleshootingTeledyne API Ultrafine Particle Monitor - Model 651

T r o u b l e s h o o t i n g

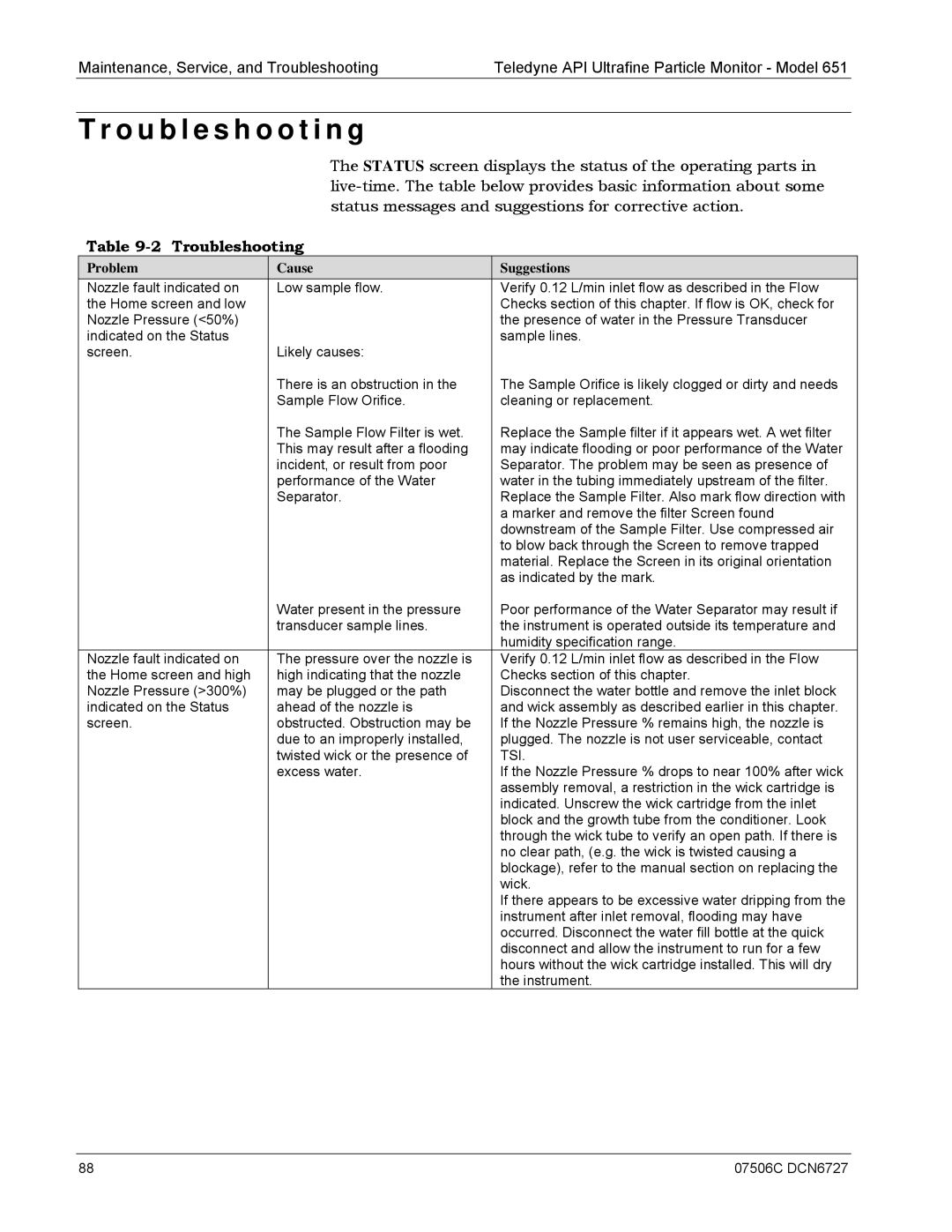

The STATUS screen displays the status of the operating parts in

Table 9-2 Troubleshooting

Problem | Cause | Suggestions |

Nozzle fault indicated on | Low sample flow. | Verify 0.12 L/min inlet flow as described in the Flow |

the Home screen and low |

| Checks section of this chapter. If flow is OK, check for |

Nozzle Pressure (<50%) |

| the presence of water in the Pressure Transducer |

indicated on the Status |

| sample lines. |

screen. | Likely causes: |

|

| There is an obstruction in the | The Sample Orifice is likely clogged or dirty and needs |

| Sample Flow Orifice. | cleaning or replacement. |

| The Sample Flow Filter is wet. | Replace the Sample filter if it appears wet. A wet filter |

| This may result after a flooding | may indicate flooding or poor performance of the Water |

| incident, or result from poor | Separator. The problem may be seen as presence of |

| performance of the Water | water in the tubing immediately upstream of the filter. |

| Separator. | Replace the Sample Filter. Also mark flow direction with |

|

| a marker and remove the filter Screen found |

|

| downstream of the Sample Filter. Use compressed air |

|

| to blow back through the Screen to remove trapped |

|

| material. Replace the Screen in its original orientation |

|

| as indicated by the mark. |

| Water present in the pressure | Poor performance of the Water Separator may result if |

| transducer sample lines. | the instrument is operated outside its temperature and |

|

| humidity specification range. |

Nozzle fault indicated on | The pressure over the nozzle is | Verify 0.12 L/min inlet flow as described in the Flow |

the Home screen and high | high indicating that the nozzle | Checks section of this chapter. |

Nozzle Pressure (>300%) | may be plugged or the path | Disconnect the water bottle and remove the inlet block |

indicated on the Status | ahead of the nozzle is | and wick assembly as described earlier in this chapter. |

screen. | obstructed. Obstruction may be | If the Nozzle Pressure % remains high, the nozzle is |

| due to an improperly installed, | plugged. The nozzle is not user serviceable, contact |

| twisted wick or the presence of | TSI. |

| excess water. | If the Nozzle Pressure % drops to near 100% after wick |

|

| assembly removal, a restriction in the wick cartridge is |

|

| indicated. Unscrew the wick cartridge from the inlet |

|

| block and the growth tube from the conditioner. Look |

|

| through the wick tube to verify an open path. If there is |

|

| no clear path, (e.g. the wick is twisted causing a |

|

| blockage), refer to the manual section on replacing the |

|

| wick. |

|

| If there appears to be excessive water dripping from the |

|

| instrument after inlet removal, flooding may have |

|

| occurred. Disconnect the water fill bottle at the quick |

|

| disconnect and allow the instrument to run for a few |

|

| hours without the wick cartridge installed. This will dry |

|

| the instrument. |

88 | 07506C DCN6727 |