Maintenance, Service, and Troubleshooting | Teledyne API Ultrafine Particle Monitor - Model 651 |

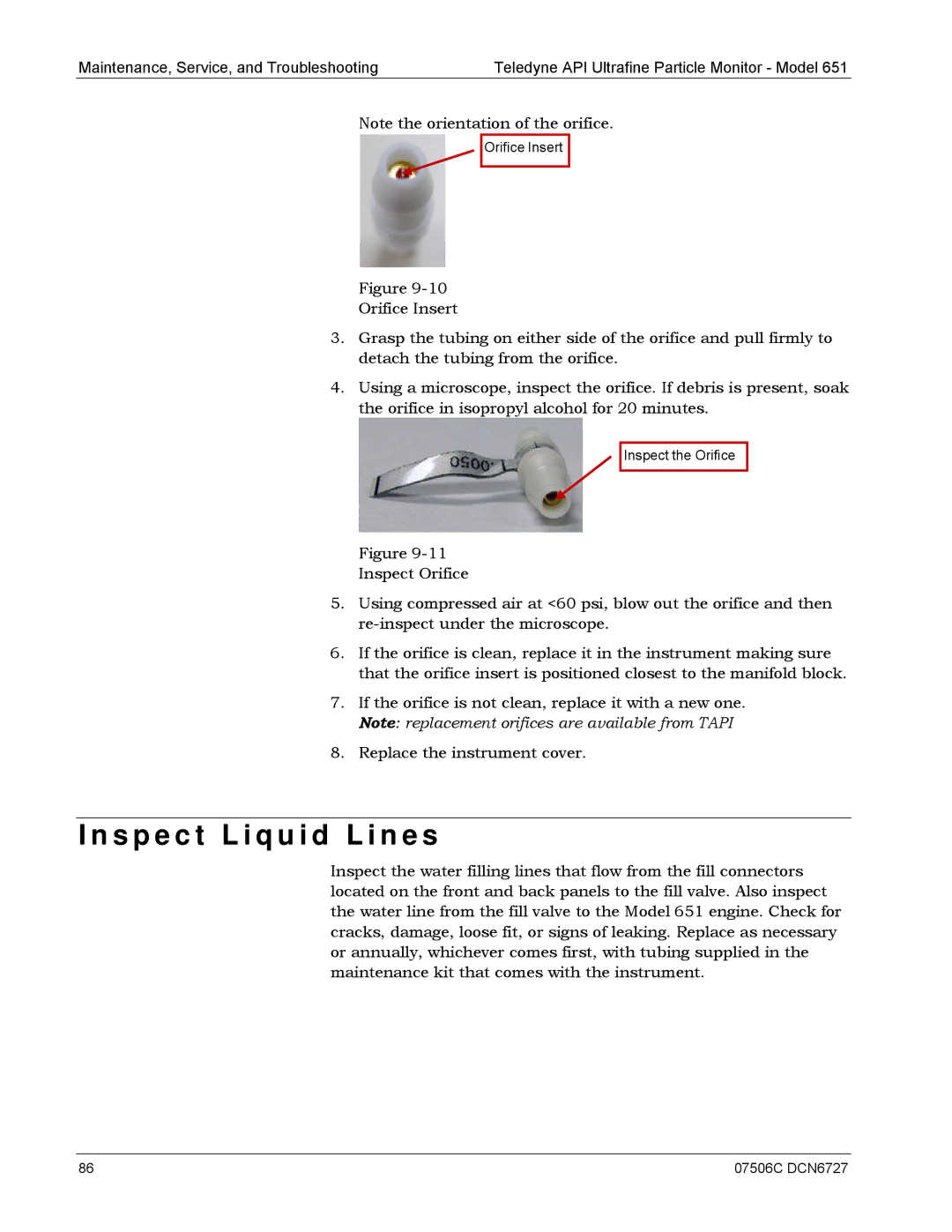

Note the orientation of the orifice.

Orifice Insert

Figure

Orifice Insert

3.Grasp the tubing on either side of the orifice and pull firmly to detach the tubing from the orifice.

4.Using a microscope, inspect the orifice. If debris is present, soak the orifice in isopropyl alcohol for 20 minutes.

Inspect the Orifice

Figure

Inspect Orifice

5.Using compressed air at <60 psi, blow out the orifice and then

6.If the orifice is clean, replace it in the instrument making sure that the orifice insert is positioned closest to the manifold block.

7.If the orifice is not clean, replace it with a new one. Note: replacement orifices are available from TAPI

8.Replace the instrument cover.

I n s p e c t L i q u i d L i n e s

Inspect the water filling lines that flow from the fill connectors located on the front and back panels to the fill valve. Also inspect the water line from the fill valve to the Model 651 engine. Check for cracks, damage, loose fit, or signs of leaking. Replace as necessary or annually, whichever comes first, with tubing supplied in the maintenance kit that comes with the instrument.

86 | 07506C DCN6727 |