| Teledyne API Ultrafine Particle Monitor - Model 651 |

| Maintenance, Service, and Troubleshooting |

| |

|

|

|

|

| |

| Problem | Cause | Suggestions |

| |

| Home screen displays Inlet | There is an obstruction in the | 1. | Check that there are no kinks in the tubing |

|

| Pressure Fault. Status | aerosol or Model 651 inlet. |

| ||

|

| upstream of the inlet. |

| ||

| screen displays a low inlet |

|

|

| |

|

| 2. | Check the inlet screen assembly for obstructions. |

| |

| pressure reading (in red). |

|

| ||

|

| 3. | Remove the inlet screen assembly. |

| |

|

|

|

| ||

|

|

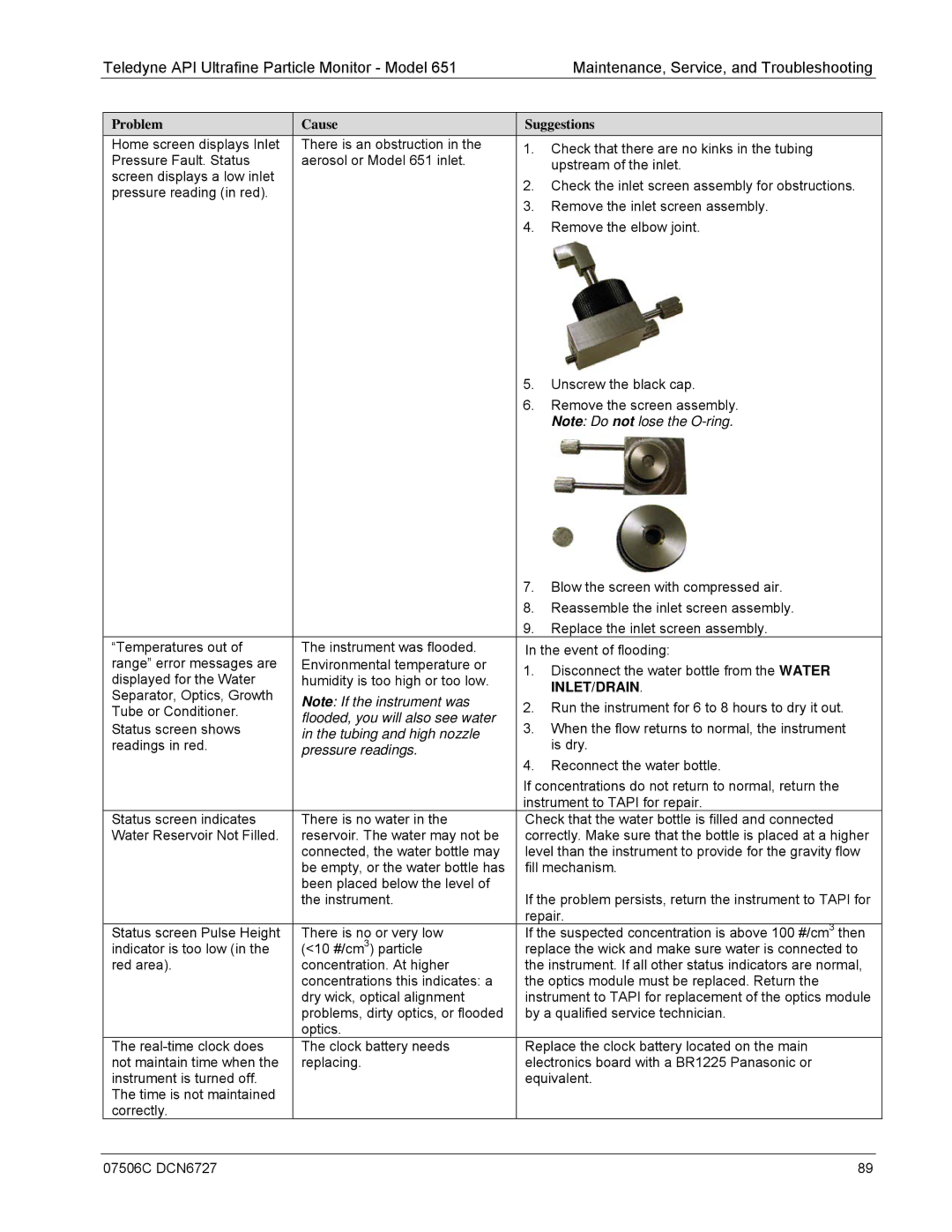

| 4. | Remove the elbow joint. |

|

5. Unscrew the black cap.

6. Remove the screen assembly. Note: Do not lose the

|

| 7. Blow the screen with compressed air. | ||

|

| 8. Reassemble the inlet screen assembly. | ||

|

| 9. Replace the inlet screen assembly. | ||

“Temperatures out of | The instrument was flooded. | In the event of flooding: | ||

range” error messages are | Environmental temperature or | 1. | Disconnect the water bottle from the WATER | |

displayed for the Water | humidity is too high or too low. | |||

| INLET/DRAIN. | |||

Separator, Optics, Growth | Note: If the instrument was |

| ||

2. | Run the instrument for 6 to 8 hours to dry it out. | |||

Tube or Conditioner. | ||||

flooded, you will also see water | ||||

Status screen shows | 3. | When the flow returns to normal, the instrument | ||

in the tubing and high nozzle | ||||

readings in red. |

| is dry. | ||

pressure readings. |

| |||

| 4. Reconnect the water bottle. | |||

|

| |||

|

| If concentrations do not return to normal, return the | ||

|

| instrument to TAPI for repair. | ||

Status screen indicates | There is no water in the | Check that the water bottle is filled and connected | ||

Water Reservoir Not Filled. | reservoir. The water may not be | correctly. Make sure that the bottle is placed at a higher | ||

| connected, the water bottle may | level than the instrument to provide for the gravity flow | ||

| be empty, or the water bottle has | fill mechanism. | ||

| been placed below the level of |

|

| |

| the instrument. | If the problem persists, return the instrument to TAPI for | ||

|

| repair. | ||

Status screen Pulse Height | There is no or very low | If the suspected concentration is above 100 #/cm3 then | ||

indicator is too low (in the | (<10 #/cm3) particle | replace the wick and make sure water is connected to | ||

red area). | concentration. At higher | the instrument. If all other status indicators are normal, | ||

| concentrations this indicates: a | the optics module must be replaced. Return the | ||

| dry wick, optical alignment | instrument to TAPI for replacement of the optics module | ||

| problems, dirty optics, or flooded | by a qualified service technician. | ||

| optics. |

|

| |

The | The clock battery needs | Replace the clock battery located on the main | ||

not maintain time when the | replacing. | electronics board with a BR1225 Panasonic or | ||

instrument is turned off. |

| equivalent. | ||

The time is not maintained |

|

|

| |

correctly. |

|

|

| |

07506C DCN6727 | 89 |