Mobile Printers

Proprietary Statement

Product Improvements

Contents

QL series configurations and Parts

Description

Operating Modes

Printing Technology

Communications

Diagnostic Tools

Introduction to Label Vista

Creating a Configuration Label

Printing a Diagnostic Label

Sample Configuration Label

Peripherals installed

Configuration Label Example

Equipment Required For Label Vista

Using Label Vista

Starting Label Vista

Equipment Required

Running The Software

QL Component Replacement Procedures

Using the QL Product Configuration Code

Additional information

Standard Control Panel

Troubleshooting

Optional LCD Control Panel

Troubleshooting Topics

No power

Poor or faded print or flashing

RMAN-QLS-002 rev. a Repair Procedures

QL220/220 Plus Repair Path

QL320 & QL420 Repair Path

MLB

Tools and Supplies

Storage and Handling

Installing the Media Cover

Media Cover, QL 220- RK18236-1 & QL220 Plus- RK17735-015

Tools Needed

Removing the Media Cover

RMAN-QLS-002 rev. a Repair Procedures

Media Cover, QL 320, QL 320 Plus & QL 420,QL 420 Plus

Model Kit p/n Comments

Installing the Media Cover

RMAN-QLS-002 rev. a Repair Procedures

Media Guide Plate Assembly, QL220/220 Plus

Removing the Media Guide Plate Assembly

Installing the Media Guide Plate Assembly

Removing the Media Assembly

Media Guide Assembly, QL320/320 Plus

Installing the Media Assembly

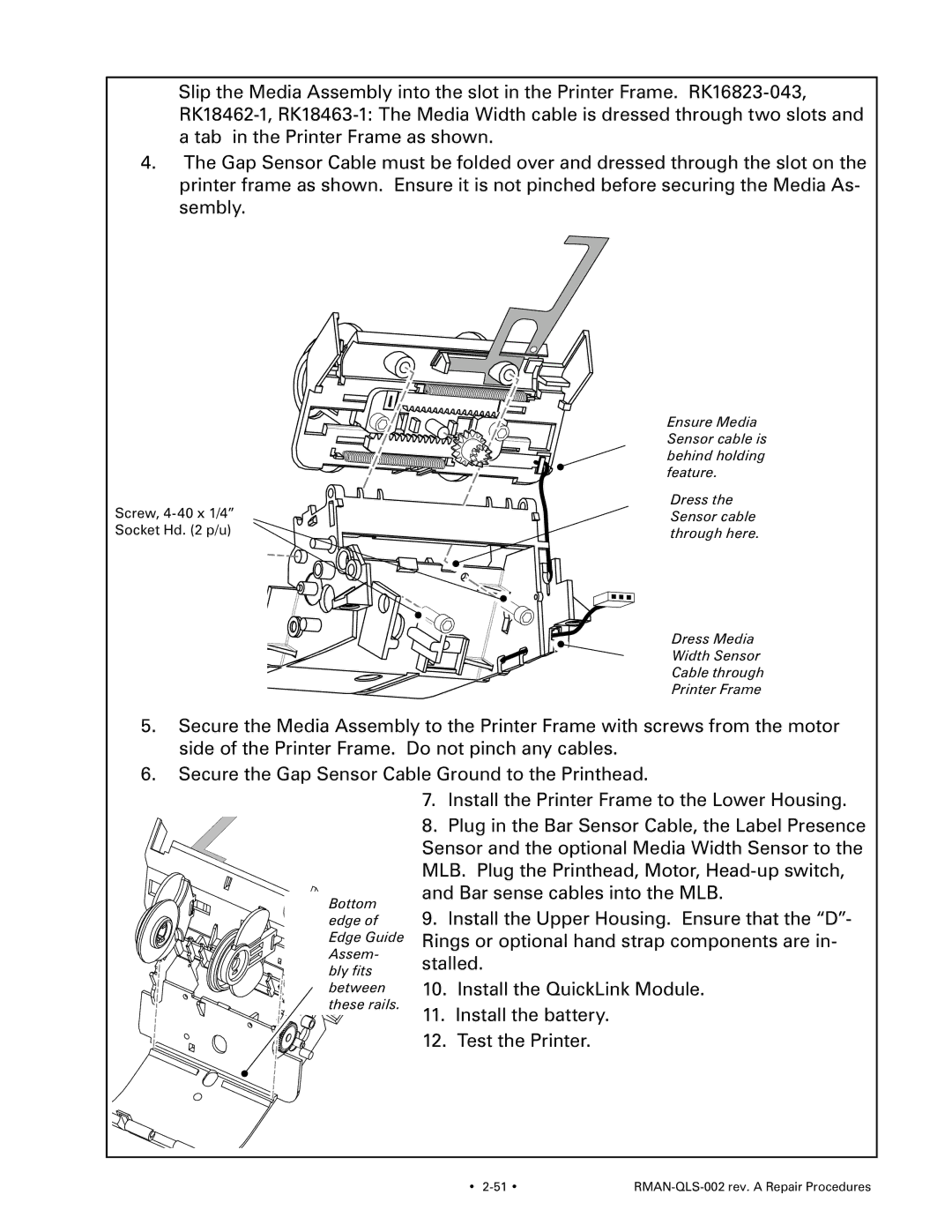

Ensure Media Sensor cable is behind holding feature

Media Guide Assembly, QL420/420 Plus

Kit p/n Description Type

Module

Media Support Disks, QL Series

Install new Media Support Disks

Remove the Media Support Disks

Changing the Media Core Size

Changing Media type

Media Guide Rollers, QL420/QL 420 Plus AN16753-003

Replacing the Media Rollers

Installing the Gear and Platen

AN16792-008- Installing the Peeler Bar

AN16792-009- Installing the Scraper

Platen/Gear Kits, QL220/QL 220 Plus AN16972-008

Installing the Scraper

Platen/Gear Kits, QL320/320 Plus- AN16861-013 & AN16861 014

Replacing the Platen Assembly

Platen/Gear Kits, QL420/420 Plus- AN16753-021

Introduction

Preparation

Remove the old Platen Assembly

Upper Housing /Wireless Modules-QL220 & QL 220 Plus

Removing the Upper Housing

Installing the Upper Housing

Set New Parameters

Upper Housing, QL320- RK18233-1

Installing the Upper Housing

Upper Housing, QL420/420 Plus- AN16753-007

Assemble the P.C. Board Cover

Housing, Upper p/n DA16394-1

Assemble P.C. Board Cover

Install the Upper Housing

Label Presence Sensor, QL320- AN16861-015

Remove the Upper Housing

Assemble the Sensor Support

Install Label Present Sensor Option

Re-install the Upper Housing

Installing a Wlan Radio and Antenna

Install the Radio

Finish the Assembly

Assemble the Antenna

QL 320/320 Plus & QL 420/420 Plus Wireless Modules

Procedure Outline

Removing the Wireless Module

Installing the Wireless Module

Upper Housing or Wireless Module Screw, #4-40 x 3/8

Removing the Keypad

Installing the Keypad

Removing the LCD module

Installing the LCD module

Installing an LCD Keypad

Installing a Membrane Key Pad

Installing the Printer Frame

Printer Frame, QL220/220Plus- AN16972-001

Install the new Printer Frame Assembly

Removing the Printer Frame

RMAN-QLS-002 rev. a Repair Procedures

From # of connections CPU Connector #

Connector Door, QL 220 /QL220 Plus AN16972-021

Remove the Connector Door

Attach the new Connector Door

Remove the Lower Cover

Connector Door, QL420 & QL420 Plus- AN16753-020

Install the Connector Door

Installing the Motor

Motor,QL220 & QL 220 Plus AN16972-002

Motor, QL 320/320 Plus & QL420/420 Plus- RK18251-1

Removing the Motor

From # of connections CPU Connector #

Installing the Printhead

Printhead, QL220- RK18278-1 & QL 220 Plus- RK17735-016

Printhead, QL320 RK18277-1 & QL 320 Plus- RK18465-003

Printhead, QL 420- RK18252-1 & QL 420 Plus- RK17735-004

Install the new Printhead Assembly

Remove the Printhead

RMAN-QLS-002 rev. a Repair Procedures

RMAN-QLS-002 rev. a Repair Procedures

RMAN-QLS-002 rev. a Repair Procedures

RMAN-QLS-002 rev. a Repair Procedures

Installing the Latch

Latch, QL 220/QL 220 Plus- AN16972-004

RMAN-QLS-002 rev. a Repair Procedures

Latch, QL 320/ QL 320 Plus- AN16861-025

Latch, QL 420/ QL 420 Plus- AN16753-011

Removing the Latch

Latch Assembly

Installing the Peeler Shaft and Roller

Removing the Peeler Shaft and Roller

Installing the MLB

Removing the MLB

From # of connections MLB Connector #

Compatibility Switch SW1

J4 Motor

103 RMAN-QLS-002 rev. a Repair Procedures

RMAN-QLS-002 rev. a Repair Procedures 104

105 RMAN-QLS-002 rev. a Repair Procedures

RMAN-QLS-002 rev. a Repair Procedures 106

Installing the Belt Clip

Removing the Belt Clip

QL220 QL320

QL420

AN16753-010 Install the D-Rings

AN16753-009 Install the Carrying Strap

Installing the D Rings

Installing the Bushings

Removing the D Rings

Removing the Bushings

Install the Kickstand QL 220 ilustrated

Removing the Battery Pack

Installing the Battery Pack

Using the Product Configuration Code

Component Replacement Procedures

Repair Services contact Information USA

Factory Repair and Parts Ordering Procedure

Europe

QL 220 Product Configuration Code PCC

PCC Notes

Accessory Parts not illustrated

PCC Example

QL 220 & 220 Plus Replacement Kits

KIT RPR QL2 Media Guide W/BELT

Shaded items are not illustrated

QL 220 & 220 Plus Parts

Printer Mechanism Exploded View

QL 220 & 220 Plus Parts- Unit Exploded View

QL 320 & 320 Plus Product Configuration Code

PCC

Interpreting the PCC Code

QL 320 & 320 Plus Replacement Kits

Assy Module Irda QL3/4 QL

KIT RPR QL 320 Media GUIDE/MW

Unit Exploded View

Pcmcia Radio Options

QL 420 & 420 Plus Product Configuration Code

Parts Not Illustrated

QL 420 & 420 Plus Replacement Kits

KIT Repair QL4 PRINTHD/SENSOR

Self TAP SCREW, M3X6, QTY

RMAN-QLS-002 rev. a Replacement Kits 130

Pcmcia Option