der the retainer features and sits on the locator pin in the Lower Housing.

4.Secure the Ground Strap with 1 Screw and Nylon Washer.

5.Install a second Screw to secure the MLB.

6.Set the Compatibility Switch per PCC digit 10

If PCC digit 10 = 0, set SW1 to NORMAL CCW (turn fully counterclockwise ). If PCC digit 10 = S, set SW1 to OTHER CW (turn fully clockwise).

7.Install the Keypad.

8.Install the Upper Housing.

9.Install the QuickLink module.

10.Install the Battery Pack.

11.Load the application. You must reload the printer’s original application files. The application files can either be stored on your local system or can be down- loaded from the factory’s database.

![]() You must have authorization from Zebra to access the application files from the factory.

You must have authorization from Zebra to access the application files from the factory.

12.Calibrate the Sensors. Using the gray and white swatches, follow the

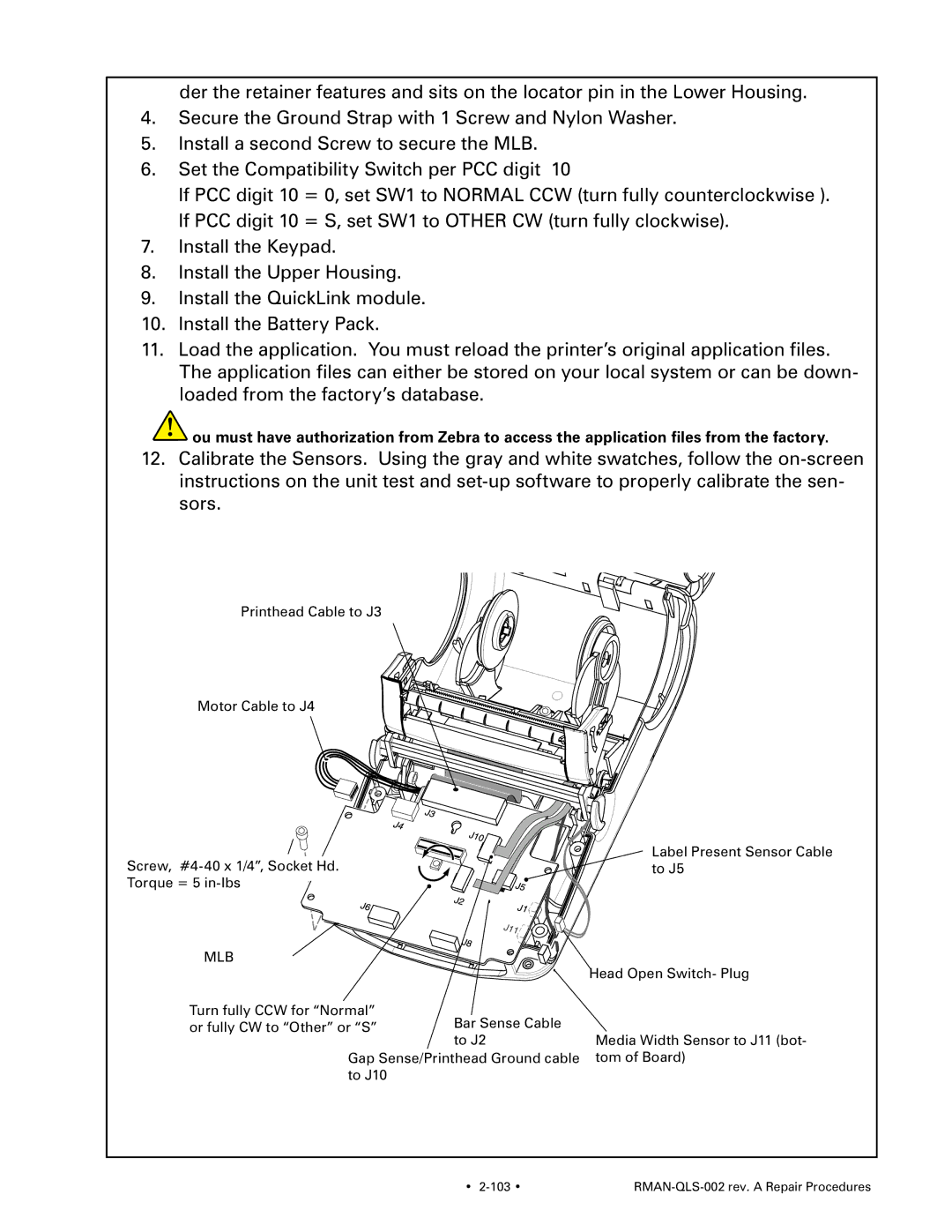

Printhead Cable to J3

Motor Cable to J4

Screw,

Torque = 5

MLB

Turn fully CCW for “Normal”

or fully CW to “Other” or “S” Bar Sense Cable to J2

Gap Sense/Printhead Ground cable to J10

Label Present Sensor Cable to J5

Head Open Switch- Plug

Media Width Sensor to J11 (bot- tom of Board)

• |

|