CNC

Page

Page

Controls

Controls

Navigation keys KeyFunction

Axis Jog keys KeyFunction

Keyboard Equivalent Key Strokes Function

Keyboard Installation

Alt + c

Arrows

Manual Information

Message symbols

CNC model NC software number

Model, Software and Features

Intended place of operation

Viii

689

New Functions of Software

Changed Functions of Software

Contents

Xii

Table of Contents

Xiv

Machining Fundamentals

Manual Data Input

Xvi

Tool Data

Xvii

Program Management

Xviii

Programming Canned Cycles, sub-programs

3500i

Probing Cycles

Drawing Programs

Running a Program on the Machine

Xxii

Xxiii

Xxiv

Code Edit, Help, & Advanced Features

Xxv

Advanced Programming

Xxvi

11.5 Four Axis Programming

Introduction

Introduction

ACU-RITE conversational, and G-code formats

Powering Up the CNC Machine

Activating/Resetting the Servos

Stop, Servo Reset, and CNC Shutdown

Reset the servos as follows

Emergency Stop E-STOP

Writing Programs

Operating Panel with Touch Screen display

Visual Display Unit

Screen Navigation

Operator Prompts

Menus, Dialogues, and Forms

Cursor

Main Operating Modes

General Operating Guidelines

Sub Modes

Visual

Display Unit

Upper Menu and Status Information Bar

Machine function buttons

Keyboard

Additional Buttons

Unit

Special Characters

Programming Sliders

Drag Bar

Numeric touch pad

Advanced Function buttons

Calculator

Context Sensitive Help

Using Context Sensitive Help

Button Function

Console Key Pad

Display navigation

Operating Mode Screens Main Operating Mode Screens

Manual Data Input

Program Management Screen

Mode Screens

Draw View

Program Run

Touch probes

Accessories

TS 220, TS 640 and TS 440 touch trigger probes

Electronic Edge Finder

HR electronic hand wheels

TT 140 tool touch probe for tool measurement

Machining Fundamentals

Position encoders and reference marks

Fundamentals of Positioning

Reference system on milling machines

Reference system

Polar coordinates

Designation of the axes on milling machines

Tool axis Principal axis Minor axis

Setting the pole and the angle reference axis

Angle Measurements

Absolute work piece positions

Absolute and incremental work piece positions

Incremental work piece positions

Fixture Offsets

Setting the datum

Fundamentals of Positioning

Manual Machine Positioning

Jog Mode Moves

Overriding the Spindle RPM

Adjusting the Feedrate

Manual Machine Positioning

Manual Data Input

Overview

Manual Data Input MDI

Manual Data Input Screen

Modes set from the Manual Data Input screen

Manual Data Input Mode Settings

Manual Data Input Menu Bar

MDI Menu Page two

Mill Arc manual data input

Manual Data Input Operations

Mill Arc manual data input View

Drill Cycles

Manual Data Input Cycles

Pocket Cycle Example

Rectangular Pocket Cycle data input View

Block History

Code MDI

Zero Axes

MDI Touch Screen Feature Dialogues

Program Preset

Move to Target Location

Tool

Offset

Basic Modals

Feed and Speed

Manual Data Input MDI

MDI Teach

Button Function

Tool Management

Tool Table / Tool Management

Tool Table

Tool Compensation Required Data

Locating the Tool Table

Tool numbers / Tool names

Sign for the length difference ΔL

Tool Table Menu Bar

Editing the tool table

Second Menu Bar

Clearing the current tool table

Clearing an entire line of tool data

Find

Finding a tool using text

Teach, and Teach Program

Clear Feature

Tool Table Structure

Feeds & Speeds Overview

Feeds & Speeds Table

Feeds & Speeds Table Structure

Tool Diameter

Column Description Tool Number

Tool Length

Number

Using the Feeds & Speeds Table

Simulation Tool and Offset Tables

Codes, and Tool Activation

Tool Data

Activating Offsets via the Program

T1 Format Description

Entering Tool Length Offsets in the Tool Table

Tool-Length Offsets

Diameter Offset in Tool Table

Contouring without radius compensation

Tool Radius Compensation

Contouring with radius compensation

Radius compensation Machining corners

Line Tangent Entry Move

Ramping into a Compensation Move

Line Perpendicular Entry Move

Line Arc Tangent Entry Move

Arc Tangent Entry Move

Special Code Temporary Change of Tool Diameter

Path of Tool During Tool Compensation

Tool Compensation Path

Compensation Around Acute Angles

Intersecting Points

General Precautions

Tool Life Management

Fixture Offsets Tool menu

Activate Tool Life Management

Lock, or Unlock a Tool

Replacement Tool RT

Tool Data

Program Management

Program Management Introduction

Accessing Program Management

Program Screen Description

Program Manager Menu Bar

Utility Function Buttons

Display window arrangement

Folder Filter

Program Manager Functions

Advanced Folder Filter

Preview button

Utility Button Functions

Paste Program button

Program Properties

Sorting Folder Contents

Recycle Bin

USB Access

Creating a New Part Program

Creating, Editing, & Selecting to Run

Editing an Existing Part Program

Program selection

Selecting a Program To Run

Conversational Editing

Getting Started

Conversational Programming

Direct

From Draw

101

Program Edit Screen

Program Edit buttons

Milling Button

Conversational Data Input Cycles

103

Milling Feature Buttons

105

More Milling Button

Drill Features Button

107

Pocket Cycles Button

RMS

Other Cycles Button

Mark a program block

Program Editing

Unmark a block, or blocks

109

Inserting a program block

Deleting a program block

Copy/Paste Blocks in a program

Canceling edits to a program block

Moving Blocks in a program

111

Editing an existing block

Restore edits to a program block

Find Specific Text or Code in a program

Program Text Editing

113

Preview Side Bar Menu

Program Edit Preview

115

Preview Features Menu

Program / Display Relation

Programming Canned Cycles, sub-programs

Round/Chamfer

Explaining Basic Cycles

Corner Rounding

Line-to-Line Corner Rounding

Arc-to-Arc Corner Rounding

Line-to-Arc Corner Rounding

Chamfering

119

Rapid Move

Rapid

Rapid Move EndPoint

Field Code Description

Rapid Move Angle

Rapid Move Angle and Radius

121

Rapid Move Radius

Rapid Move Angle and Y

Rapid Move Radius and Y

Line

Line Move

123

Line Move EndPoint

Line Move Angle

Line Move Angle and Radius

125

Line Move Radius

Line Move Angle and Y

127

Line Move Radius and Y

Arc Move

Arc

129

Arc Move Radius and EndPoint

Arc Move Center and EndPoint

131

Arc Move Center and Angle

Using Arc Center and EndPoint to create a circle

133

Dwell

Plane Selection

135

Reference Point Return

Fixture Offset Work Coordinate System Select

Unit Inch/MM

Dimension Abs/Inc

137

Absolute Zero Set

139

Block Form

Temporary Path Tolerance

141

System Data

FeedRate 4th-Axis

FeedRate

Functions

Spindle RPM

143

Tool Definition and Activation

Block Description

Repeat Blocks

145

0000

Canned Cycles

Canned Cycles

147

Drilling, Tapping, and Boring

Drilling Cycles

Basic Drill Cycle

Peck Drill Cycle

Counterbore Drill Cycle

149

Tapping Cycle

Boring Unidirectional Cycle

Boring Bidirectional Cycle

151

Chip Break Cycle

153

Flat Bottom Boring Cycle

Drill Bolt Hole Cycle

155

Drill Pattern Cycle

Mill Cycle

Milling Cycles

157

EndMill Cycle

159

Face Mill Cycle

160

161

Hole Mill Cycle

Thread Mill Cycle

163

164

165

Circular Profile Cycle

166

167

Rectangular Profile Cycle

168

Pocket Cycle Overview

Pocket Cycles

169

Draft Angle Pocket Cycle

171

Rectangular Pocket Cycle

173

Circular Pocket Cycle

175

Plunge Rectangular Pocket Cycle

177

Plunge Circular Pocket Cycle

179

Frame Pocket Cycle

181

Ring Pocket Cycle

183

Slot Cycle

185

Circular Slot Cycle

187

Irregular Pocket Cycle

189

Islands

191

Bottom Finish

Side Finish

Programming the Engrave Cycle

Engraving Cycles

193

194

195

Programming the Arc Engrave Cycle

’clock position. Optional

Tool, and Spindle Probe cycles

Probing Cycles

197

Tool Probe Cycles

199

Tool Probe Calibration Cycle

200

201

Tool Length and Diameter Offset Preset

202

203

To use the automatic tool preset

205

206

207

Manual Tool-Length Offset Preset

209

210

211

Manual Tool Diameter Measure for Special Tools

212

213

Tool Breakage, Length and Diameter Wear Detection

215

216

Spindle Probe

Spindle Probe Settings

Spindle Probe Cycles

217

Spindle Probe Calibration Cycle

219

Edge Finding

221

Outside Corner Finding

222

223

Inside Corner Finding

224

225

Inside/Outside Boss/Hole Finding

226

227

Inside/Outside Web Finding

228

229

Protected Probe Positioning

Skew Compensation

231

232

233

Using the Z Work Offset Update Feature

Sub-program information

Sub-programs

Overview

Ending the Main Program

Ending a sub-program

Defining a sub-program

Calling a sub-program

235

Looping a sub-program

237

Rotate, Mirror, and/or Scale a sub-program

238

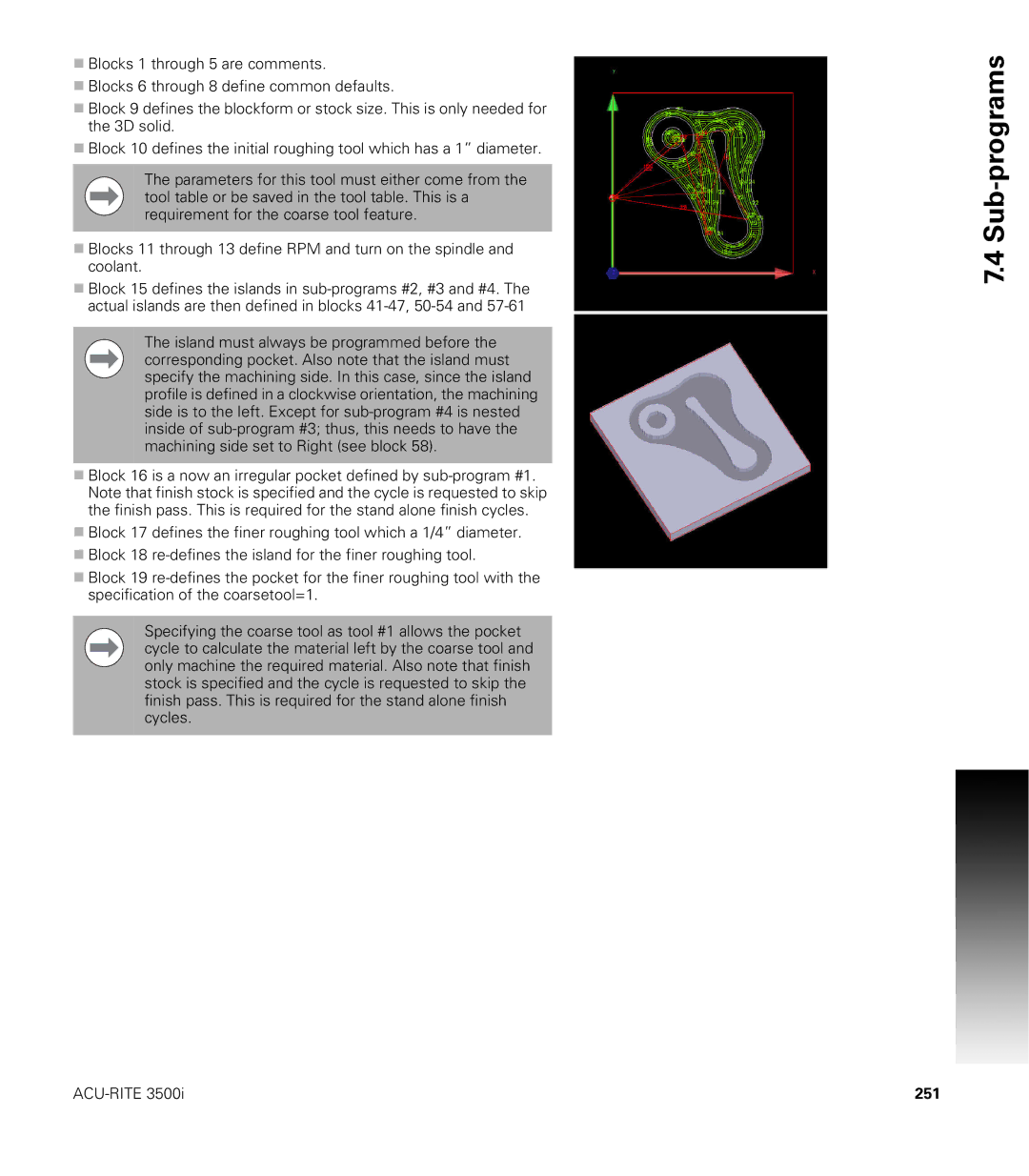

Pocket/Island example

Pocket and Islands example

239

240

241

242

243

244

245

246

247

248

249

250

251

252

Drawing Programs

Viewing Programs

Draw

255

Starting Draw

View Options Menu

257

Adjust View Menu

Zoom

Adjust Block Form

Pan Drawing View

Rotate Drawing View

259

Line View Adjustments

261

Draw Options

Sim Tools

Running a Program on the Machine

Running a program

Auto mode

Modes of Programmed Operation

Starting a program

Clearing a Messages

Pause, or Stop a running program

265

Single Step

Select a Starting Block

Block Search

267

Using Draw with running programs

Program Status Area

Program

Running

269

Parts Counter

Accessing the Tool Table

Program Run Timers

271

Key Name Function

Axis Jog keys

273

In-Program Axis Jogging

274 Running a Program on the Machine

CAM Programming

CAM Programming

CAM Mode

Recommended CAM Programming Sequence

Graphics Area 2D View Refer to Viewing Tools

CAM Mode Mouse Operations

Graphics Area 3D Tool Path Views Refer to Viewing Tools

Geometry and Shapes

Activating CAM Mode

CAM Mode Screen

279

Creating a New Program

CAM Mode buttons

Geometry Toolbar buttons Button Function

Point Editing

Point Tool buttons

281

Line Tool buttons

283

Editing a Line

Circle Editing

Circle Tool buttons

285

Shape Tool buttons

Tool Path Buttons

287

Tool Path Data Input

Quick Coordinate Entry

Job Setup Basic tab

Coolant

Tool Action

Spindle Direction

Job Setup Advanced tab

Comment Tab

Block Form Basic tab

Drilling Cycle

Drill Cycle Chip Break

Drill Cycle Boring Unidirectional

Drill Cycle Flat Bottom Boring

295

Basic tab

Drilling dialogue

Bolt Hole tab

Setup tab

297

Comment tab

Pattern tab

299

Mill Cycle

Tool Enter the tool number to use for the cycle

301

Pocket Cycle

302 CAM Programming

Bottom tab

Pocket Finish Cycles

Side tab

303

Adding a Machining Side

305

Engraving Cycle

Adding a Program Directive

Program Directive

Modifying Tools Buttons Button Function

Modifying Toolbar

307

Viewing Tool Buttons Button Function

Viewing Tools

CAM Tool Buttons Button Function

CAM Mode buttons

309

Layers button

Selection tab

CAM Setup

Output tab

311

Tool Table tab

Display tab

313

View Buttons

Defining Geometry

Geometry

315

Completing the Geometry

316 CAM Programming

317

Finalizing the geometry

Creating the shape

DXF Entities Supported

DXF Import Feature

DXF Entities Not Supported

Importing a DXF File

Corner Radius inserting

Modifying Tools

Chamfer inserting

Delete button

Trimming Geometry

Properties button

321

Copying a Shape

Shapes

Moving a Shape

323

Tool Table

Number of Teeth

Tool Table Parameters

Chip Load Rough

Chip Load Finish

Importing a Tool Table

Setting up the Tool Table

Exporting a Tool Table

325

Tool Paths

Creating a Tool Path in CAM Mode

Tool Path Verification

Use Existing Shape

Tool Path Editing

327

Disabling, and Enabling Tool Paths

Editing a Tool Path

Deleting Tool Paths

Arranging Tool Paths Sequence

10.1

CAM Mode file types Program generated by CAM

Smart Programming

Files Created

Exercise One

CAM Example

331

Connecting the Geometry

333

334 CAM Programming

335

Creating the tool paths

336 CAM Programming

337

338 CAM Programming

Create Circle Geometry

Example Two

339

340 CAM Programming

341

Create Line Geometry

342 CAM Programming

343

Programming

344 CAM Programming

345

346 CAM Programming

347

348 CAM Programming

Code Edit, Help, & Advanced Features

Code Program Editing

Activating Edit Mode

351

When editing a program, the following buttons are available

353

Edit Features menu

354

355

Delete a Character

357

358

Overwriting Text

Inserting Text

359

360

361

Replace Specific Text, or Code in a program

Preview Features

363

Edit Help Preview

Code

Code and M-Code Definitions

Contouring Mode OFF. Modal Exact Stop Check. Activates

Shifts the location of Absolute Zero to a preset location.

In-Position Mode

Exact Stop Mode OFF. Modal Contouring Mode. De-activates

G80

367

End Mill Cycle

Code Definition

Typing in M-Codes

Typing in Address Words

369

Activating Edit Help

Edit Help

371

Help Graphic Screens

372

Multi -Segment Blocks

Basic Modal Functions

373

Drilling Cycles

Arcs

Milling and Profiles

Pocket Cycles

375

Spindle Probing

Rotation, Scaling, and Mirroring

Tool Radius Compensation

Tool Probing

377

Other G Functions

379

All M Functions

Basic M Functions

Cooling, Cleaning, and Lubrication

Tool Change

Spindle Functions

381

Advanced Programming

Code Function Spindle Speed Commands spindle speeds S

Miscellaneous M-Code

Code Function

383

Control M Codes

Order of Execution

Contouring Mode Cutting Mode

In-Position Mode Exact Stop Check

Programming Non-modal Exact Stop

385

Return from Reference Point

Setting Stroke Limit

Move Reference from Machine Datum

Block Separators

Modifiers

Modifier Function

387

Temporary Format T1 D.5500 L-1.1000

Tool Offset Modification

Block #

Tool Modification Programming Example

389

O1 * SUBPGM-1

Operators and Functions Expression

Expressions and Functions

391

Expression Function

393

Examples Ref. Example

394

Variable Description

System Variables

395

User Variables

Block Skip

Variable Programming Parametric

Example N11 #1000 = 1 *Note 0=OFF, 1=ON

397

Example N11 #1002 = 1 *Note 0=OFF, 1=ON

Select Block Skip

Parameters and Variable Registers

Contents of Variables Print

399

Setting and Direct Transfer Variables

401

Indirect Transfer

Storing Result of Computation

403

Variable Programming Examples

SET Loop Number 1 IN. DP

405

#111 = 0 * SET Side CUT Increment to

Format # Function

User Macros G65, G66, G67

407

Macro Body Structure

409

Setting and Passing Parameters

O99 * WINDOW-MACRO-CALL

G65 Macro Programming, Main

411

G65 Macro Programming, Macro sub-program

O101 * SLOTCALL.G

G66/G67 Macro Programming

413

SLOTMAC.G Program

11.4

415

Macro Programming Hole Milling Macro

X1.5 Y0 * Move to Hole Center G1 Z-.5 * Move Z to Depth

417

G64 * Contouring Mode IF#70 then * COUNTER-CLOCKWISE

419

Probe Move G31

421

Conditional Statements

If Goto

423

Unconditional Loop Repeat

Short Form Addressing

Command Abbreviation

Logical and Comparative Terms

Statement Symbol True/false Table

425

Inequality Operators Not

427

File Inclusion

TOOLCHNG.G

429

Axis Type

Four Axis Programming

Linear

Rotary

Programming Examples

Rotary Axis Programming Conventions

431

T1 *#3 Centerdrill

433

O1 * Groove

T1 * Special THD-TOOLS3500

Software Update

Procedure for updating the software

Software Update

Updating System Software

Off-Line Software

Off-Line Simulator

13.1 3500i Off-Line Software

System Requirements

Operation

Installation

Updating

439

440

441

Index

442

MDI

443

444

Page

770530-25 Ver 2014