SSteel spring isolators are a very effective and commonly used. Steel spring isolators are typically

Spring steel isolators offer the highest level of vibration isolation, however higher levels of vibration (although not detrimental) may be seen on some areas of the genset when mounted on steel springs, due to the (almost) total isolation from the foundation. The base of most steel spring isolators contains a

A common practice is to pour a concrete pad directly on top of the floor slab and to mount the genset on this pad. The purpose of the pad is to facilitate cleaning around the genset and to provide a more level base. When using this method, floor strength must support the pad and the genset. The pad should be at least 6in (150mm) thick and extend beyond the genset in all directions 12in (300mm).

Weight Of The Genset

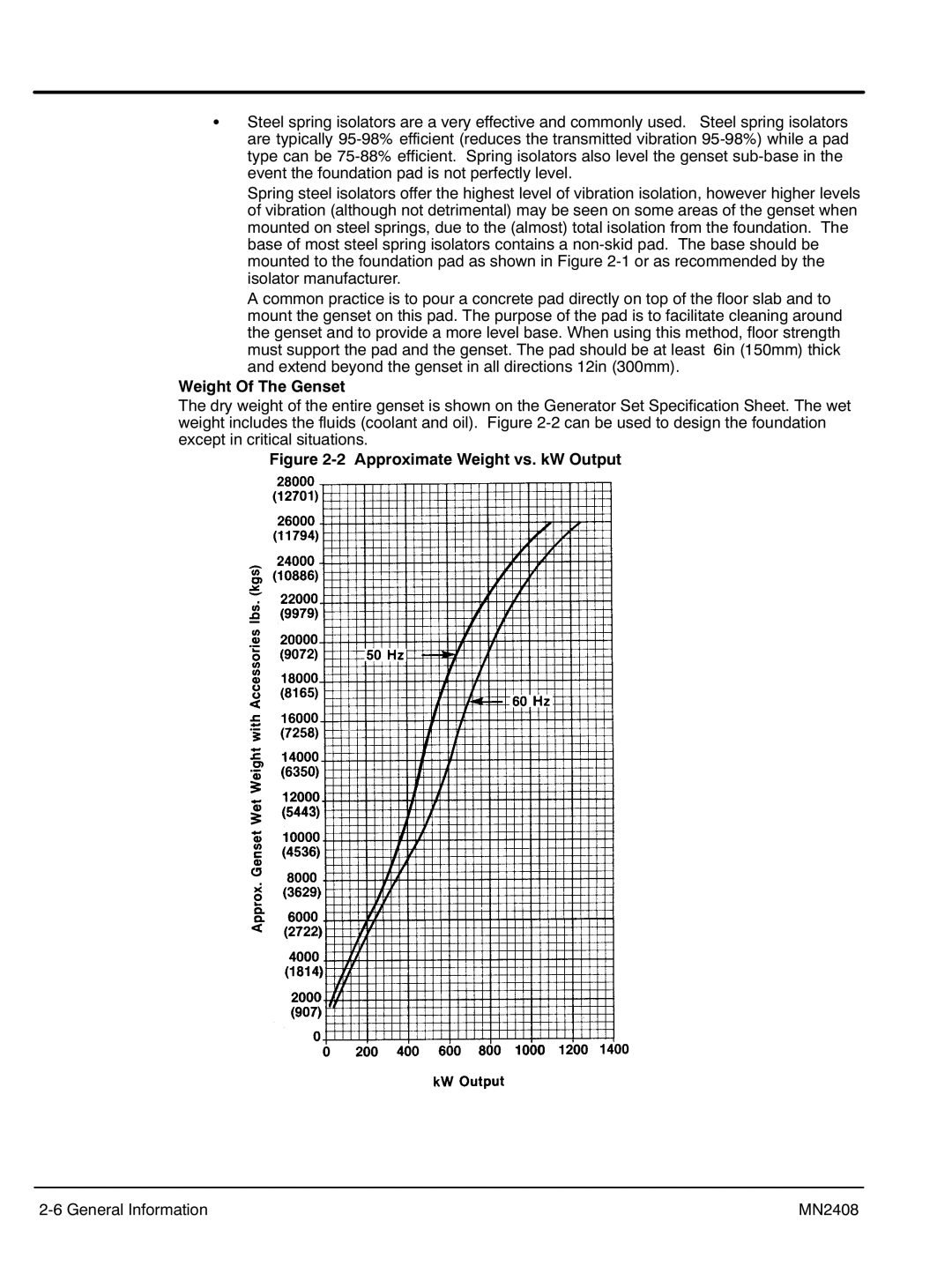

The dry weight of the entire genset is shown on the Generator Set Specification Sheet. The wet weight includes the fluids (coolant and oil). Figure 2‐2 can be used to design the foundation except in critical situations.

Figure 2‐2 Approximate Weight vs. kW Output

2‐6 General Information | MN2408 |