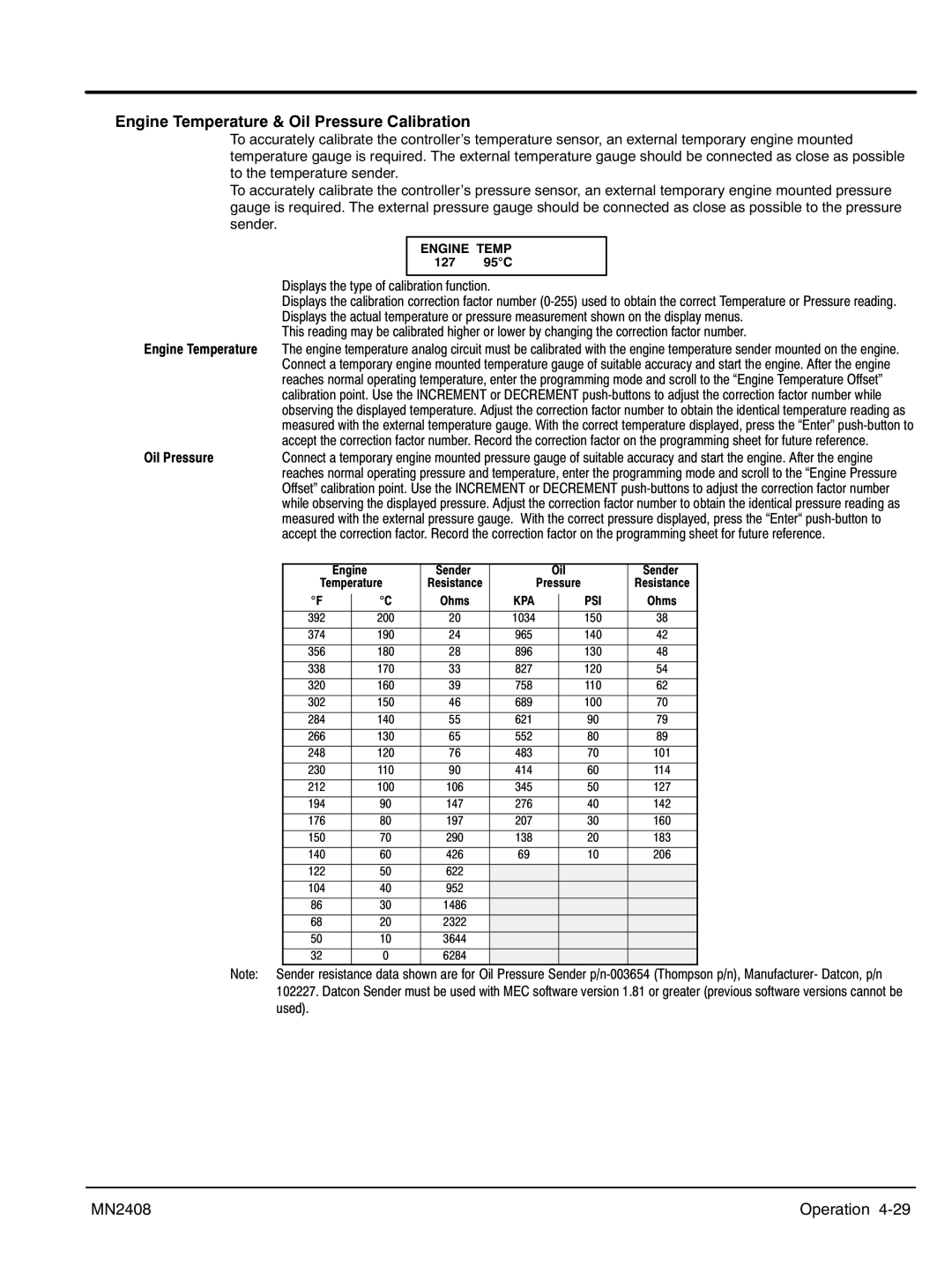

Engine Temperature & Oil Pressure Calibration

To accurately calibrate the controller's temperature sensor, an external temporary engine mounted temperature gauge is required. The external temperature gauge should be connected as close as possible to the temperature sender.

To accurately calibrate the controller's pressure sensor, an external temporary engine mounted pressure gauge is required. The external pressure gauge should be connected as close as possible to the pressure sender.

ENGINE TEMP

127 955C

Displays the type of calibration function.

Displays the calibration correction factor number

This reading may be calibrated higher or lower by changing the correction factor number.

Engine Temperature The engine temperature analog circuit must be calibrated with the engine temperature sender mounted on the engine. Connect a temporary engine mounted temperature gauge of suitable accuracy and start the engine. After the engine reaches normal operating temperature, enter the programming mode and scroll to the “Engine Temperature Offset” calibration point. Use the INCREMENT or DECREMENT

Oil Pressure | Connect a temporary engine mounted pressure gauge of suitable accuracy and start the engine. After the engine | ||||||||

| reaches normal operating pressure and temperature, enter the programming mode and scroll to the “Engine Pressure | ||||||||

| Offset” calibration point. Use the INCREMENT or DECREMENT | ||||||||

| while observing the displayed pressure. Adjust the correction factor number to obtain the identical pressure reading as | ||||||||

| measured with the external pressure gauge. With the correct pressure displayed, press the “Enter“ | ||||||||

| accept the correction factor. Record the correction factor on the programming sheet for future reference. | ||||||||

|

|

|

|

|

|

|

|

|

|

|

| Engine | Sender |

| Oil | Sender | |||

| Temperature | Resistance |

| Pressure | Resistance |

| |||

| 5F |

| 5C | Ohms | KPA |

| PSI | Ohms |

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

| 392 |

| 200 | 20 | 1034 |

| 150 | 38 |

|

| 374 |

| 190 | 24 | 965 |

| 140 | 42 |

|

| 356 |

| 180 | 28 | 896 |

| 130 | 48 |

|

|

|

|

|

|

|

|

|

|

|

| 338 |

| 170 | 33 | 827 |

| 120 | 54 |

|

|

|

|

|

|

|

|

|

|

|

| 320 |

| 160 | 39 | 758 |

| 110 | 62 |

|

| 302 |

| 150 | 46 | 689 |

| 100 | 70 |

|

| 284 |

| 140 | 55 | 621 |

| 90 | 79 |

|

|

|

|

|

|

|

|

|

|

|

| 266 |

| 130 | 65 | 552 |

| 80 | 89 |

|

| 248 |

| 120 | 76 | 483 |

| 70 | 101 |

|

| 230 |

| 110 | 90 | 414 |

| 60 | 114 |

|

| 212 |

| 100 | 106 | 345 |

| 50 | 127 |

|

| 194 |

| 90 | 147 | 276 |

| 40 | 142 |

|

| 176 |

| 80 | 197 | 207 |

| 30 | 160 |

|

| 150 |

| 70 | 290 | 138 |

| 20 | 183 |

|

| 140 |

| 60 | 426 | 69 |

| 10 | 206 |

|

| 122 |

| 50 | 622 |

|

|

|

|

|

| 104 |

| 40 | 952 |

|

|

|

|

|

| 86 |

| 30 | 1486 |

|

|

|

|

|

| 68 |

| 20 | 2322 |

|

|

|

|

|

| 50 |

| 10 | 3644 |

|

|

|

|

|

| 32 |

| 0 | 6284 |

|

|

|

|

|

Note: Sender resistance data shown are for Oil Pressure Sender

MN2408 | Operation 4‐29 |