Foundation Design

WARNING: An open bottom stationary engine generator set must be installed over noncombustible materials and shall be located such that it prevents combustible materials from accumulating under the generator set.

Foundation Checklist

A. Evaluate if a separate, isolated foundation is required for the application. B. Observe local codes on soil bearing capacity freezing and thawing.

C. Design the separate foundation for the genset and specify the appropriate concrete mix. D. Determine if the application requires vibration isolators and if so, order as a factory option. The foundation must be strong enough to support the weight of the genset and its associated equipment, must prevent any deflection of the genset base and absorb vibration produced by the rotating and reciprocating masses.

Setting The Genset On An Existing Concrete Floor Slab

SIf an existing floor is used, the floor slab must be strong enough to carry 1.50 times the genset wet weight (including coolant and oil) to accommodate dynamic loads.

SThe actual mounting arrangement (ie., surface area in contact with the floor) will determine the compressive strength required.

SThe genset should be securely fastened to the floor slab with expansion anchors that fit the mounting holes shown on the genset installation diagram.

SFor installations not expected to be permanent, elastomer pad with

SAny floor/slab surface should be as flat as possible to prevent

Vibration Isolators

SMounting to the pad, will result in overall reduced motion on other parts of the genset. The

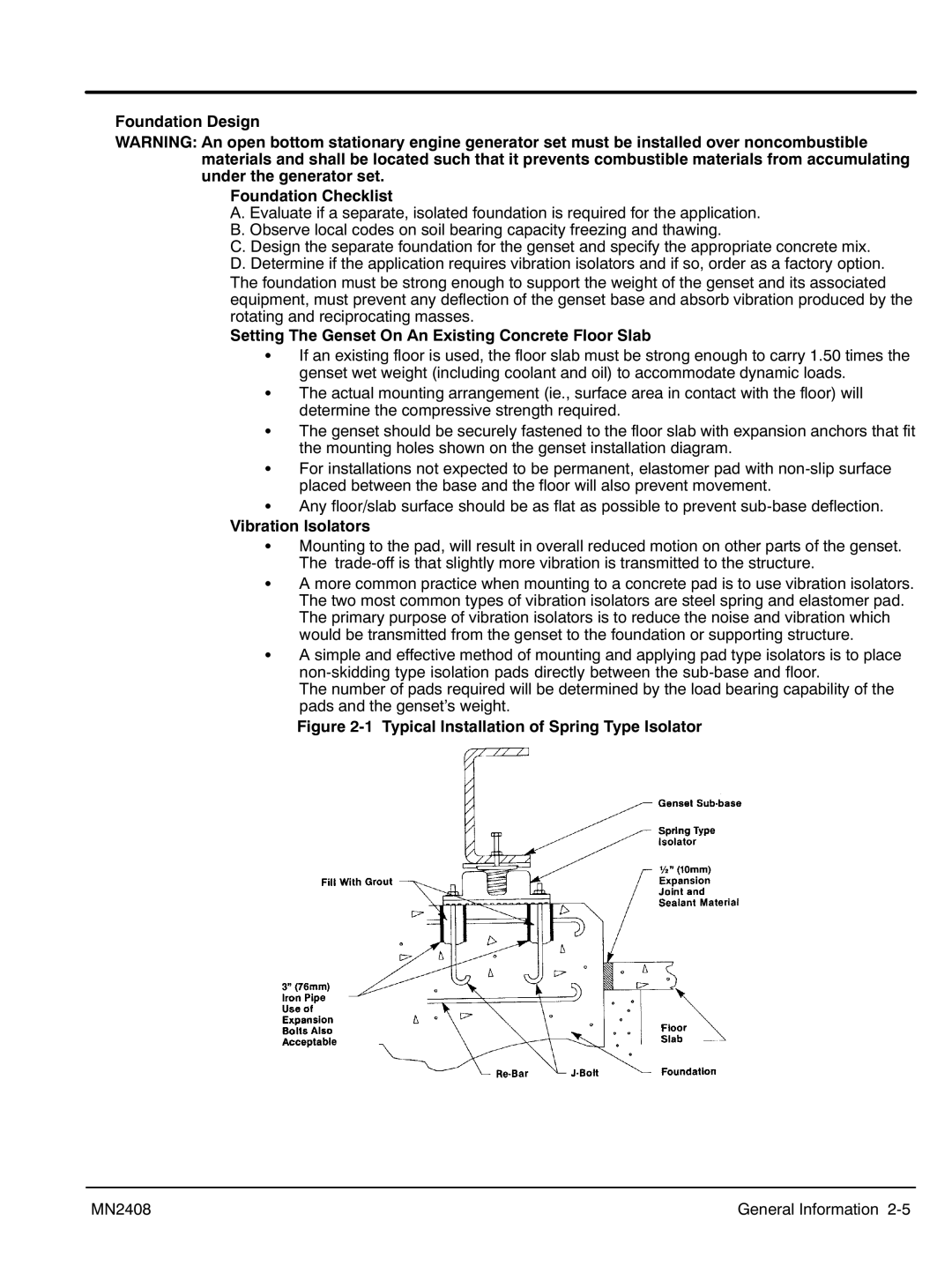

SA more common practice when mounting to a concrete pad is to use vibration isolators. The two most common types of vibration isolators are steel spring and elastomer pad. The primary purpose of vibration isolators is to reduce the noise and vibration which would be transmitted from the genset to the foundation or supporting structure.

SA simple and effective method of mounting and applying pad type isolators is to place

The number of pads required will be determined by the load bearing capability of the pads and the genset's weight.

Figure 2‐1 Typical Installation of Spring Type Isolator

MN2408 | General Information 2‐5 |