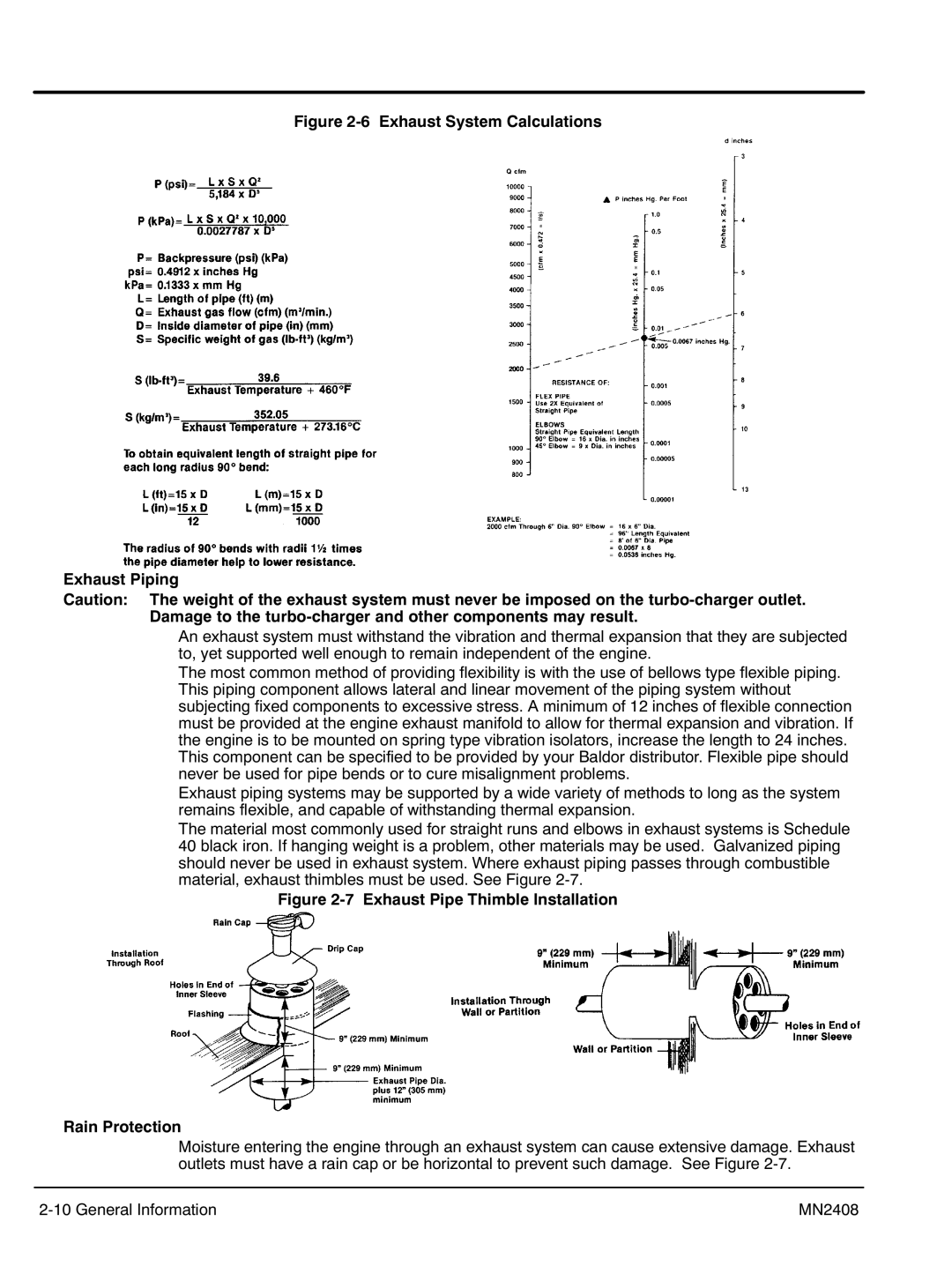

Figure 2‐6 Exhaust System Calculations

Exhaust Piping

Caution: The weight of the exhaust system must never be imposed on the

An exhaust system must withstand the vibration and thermal expansion that they are subjected to, yet supported well enough to remain independent of the engine.

The most common method of providing flexibility is with the use of bellows type flexible piping. This piping component allows lateral and linear movement of the piping system without subjecting fixed components to excessive stress. A minimum of 12 inches of flexible connection must be provided at the engine exhaust manifold to allow for thermal expansion and vibration. If the engine is to be mounted on spring type vibration isolators, increase the length to 24 inches. This component can be specified to be provided by your Baldor distributor. Flexible pipe should never be used for pipe bends or to cure misalignment problems.

Exhaust piping systems may be supported by a wide variety of methods to long as the system remains flexible, and capable of withstanding thermal expansion.

The material most commonly used for straight runs and elbows in exhaust systems is Schedule 40 black iron. If hanging weight is a problem, other materials may be used. Galvanized piping should never be used in exhaust system. Where exhaust piping passes through combustible material, exhaust thimbles must be used. See Figure 2‐7.

Figure 2‐7 Exhaust Pipe Thimble Installation

Rain Protection

Moisture entering the engine through an exhaust system can cause extensive damage. Exhaust outlets must have a rain cap or be horizontal to prevent such damage. See Figure 2‐7.

2‐10 General Information | MN2408 |