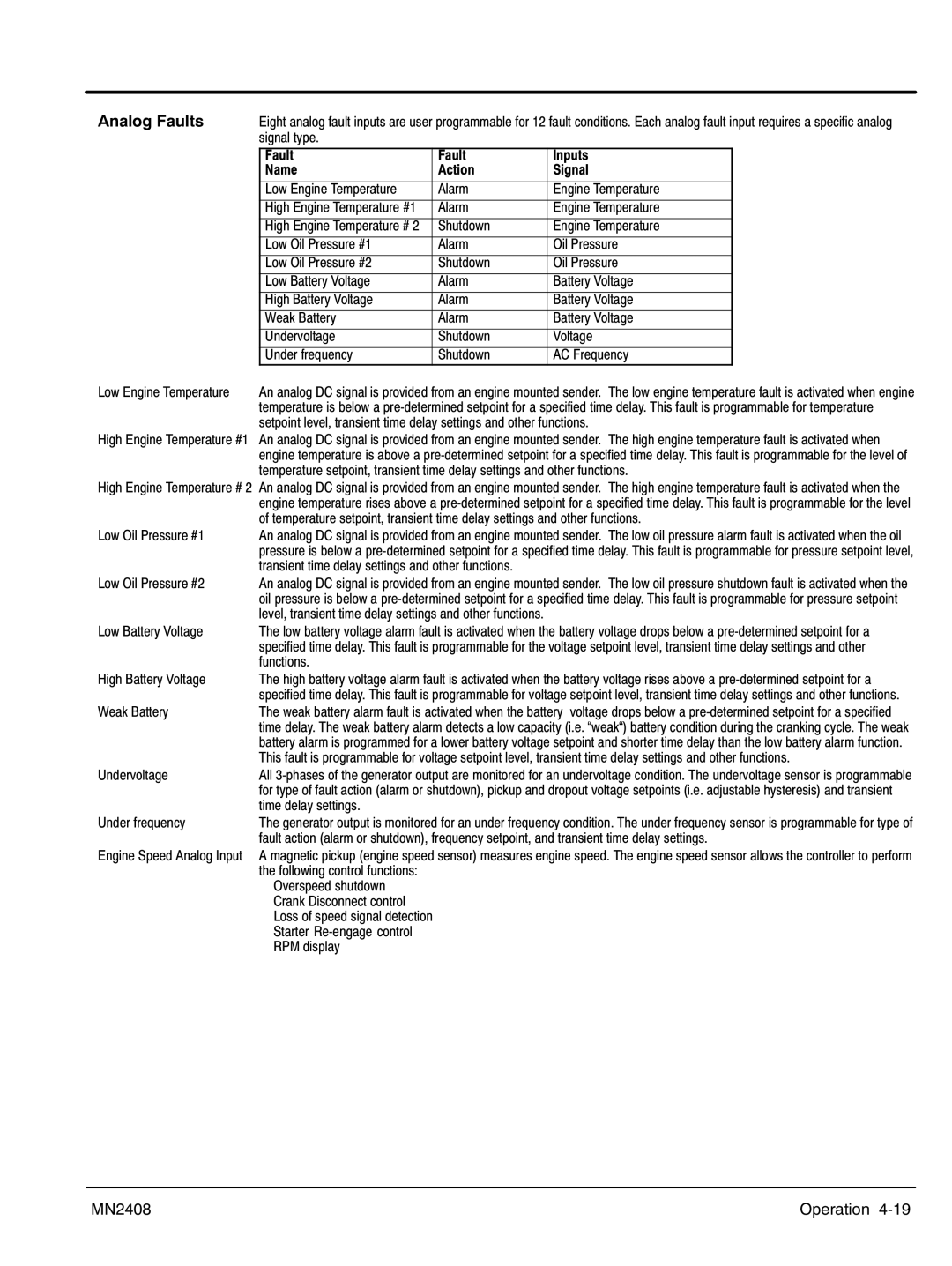

Analog Faults | Eight analog fault inputs are user programmable for 12 fault conditions. Each analog fault input requires a specific analog | |||

| signal type. |

|

|

|

|

|

|

|

|

| Fault | Fault | Inputs | |

| Name | Action | Signal |

|

|

|

|

|

|

| Low Engine Temperature | Alarm | Engine Temperature | |

| High Engine Temperature #1 | Alarm | Engine Temperature |

|

| High Engine Temperature # 2 | Shutdown | Engine Temperature |

|

| Low Oil Pressure #1 | Alarm | Oil Pressure |

|

| Low Oil Pressure #2 | Shutdown | Oil Pressure |

|

| Low Battery Voltage | Alarm | Battery Voltage |

|

| High Battery Voltage | Alarm | Battery Voltage |

|

| Weak Battery | Alarm | Battery Voltage |

|

| Undervoltage | Shutdown | Voltage |

|

| Under frequency | Shutdown | AC Frequency |

|

Low Engine Temperature | An analog DC signal is provided from an engine mounted sender. The low engine temperature fault is activated when engine | |||

| temperature is below a | |||

| setpoint level, transient time delay settings and other functions. | |||

High Engine Temperature #1 An analog DC signal is provided from an engine mounted sender. The high engine temperature fault is activated when engine temperature is above a

High Engine Temperature # 2 An analog DC signal is provided from an engine mounted sender. The high engine temperature fault is activated when the engine temperature rises above a

Low Oil Pressure #1 | An analog DC signal is provided from an engine mounted sender. The low oil pressure alarm fault is activated when the oil |

| pressure is below a |

| transient time delay settings and other functions. |

Low Oil Pressure #2 | An analog DC signal is provided from an engine mounted sender. The low oil pressure shutdown fault is activated when the |

| oil pressure is below a |

| level, transient time delay settings and other functions. |

Low Battery Voltage | The low battery voltage alarm fault is activated when the battery voltage drops below a |

| specified time delay. This fault is programmable for the voltage setpoint level, transient time delay settings and other |

| functions. |

High Battery Voltage | The high battery voltage alarm fault is activated when the battery voltage rises above a |

| specified time delay. This fault is programmable for voltage setpoint level, transient time delay settings and other functions. |

Weak Battery | The weak battery alarm fault is activated when the battery voltage drops below a |

| time delay. The weak battery alarm detects a low capacity (i.e. “weak“) battery condition during the cranking cycle. The weak |

| battery alarm is programmed for a lower battery voltage setpoint and shorter time delay than the low battery alarm function. |

| This fault is programmable for voltage setpoint level, transient time delay settings and other functions. |

Undervoltage | All |

| for type of fault action (alarm or shutdown), pickup and dropout voltage setpoints (i.e. adjustable hysteresis) and transient |

| time delay settings. |

Under frequency | The generator output is monitored for an under frequency condition. The under frequency sensor is programmable for type of |

| fault action (alarm or shutdown), frequency setpoint, and transient time delay settings. |

Engine Speed Analog Input | A magnetic pickup (engine speed sensor) measures engine speed. The engine speed sensor allows the controller to perform |

| the following control functions: |

| Overspeed shutdown |

| Crank Disconnect control |

| Loss of speed signal detection |

| Starter |

| RPM display |

MN2408 | Operation 4‐19 |