Installation The generator is completely assembled, tested and adjusted at the factory before it is shipped to you. The procedures presented in this manual are suggestions and it is the responsibility of the Owner/Operator to arrange for these procedures to be performed by licensed contractors according to all applicable codes including local codes for your Municipality/City/County and State. External connections required at the time of installation are:

1.Fuel System.

2.Electrical Connections - power wiring (optional transfer switch) and control wiring.

3.Battery (not included).

4.Ground Connection.

After installation, the post installation checks must be performed prior to starting the engine. After these checks have been performed and the system operation is verified to be good, refer to Section 5 Maintenance for periodic checks that must be performed at scheduled intervals to ensure continued operation with minimal problems.

Fuel Connections

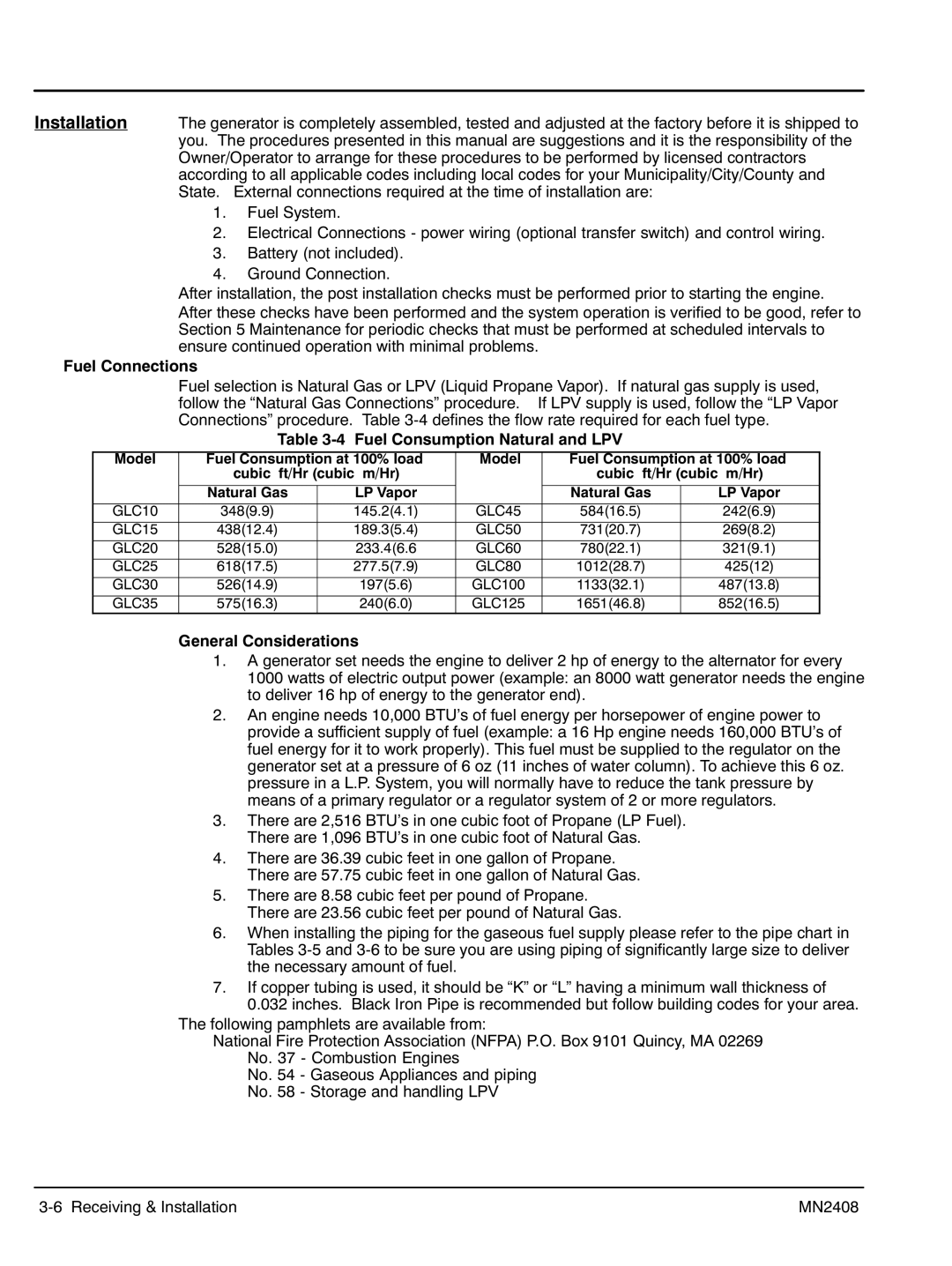

Fuel selection is Natural Gas or LPV (Liquid Propane Vapor). If natural gas supply is used, follow the “Natural Gas Connections” procedure. If LPV supply is used, follow the “LP Vapor Connections” procedure. Table 3‐4 defines the flow rate required for each fuel type.

Table 3‐4 Fuel Consumption Natural and LPV

Model | Fuel Consumption at 100% load | Model | Fuel Consumption at 100% load | |||

| cubic ft/Hr (cubic m/Hr) |

| cubic ft/Hr (cubic | m/Hr) | ||

|

|

|

|

|

|

|

| Natural Gas | LP Vapor |

| Natural Gas |

| LP Vapor |

GLC10 | 348(9.9) | 145.2(4.1) | GLC45 | 584(16.5) |

| 242(6.9) |

GLC15 | 438(12.4) | 189.3(5.4) | GLC50 | 731(20.7) |

| 269(8.2) |

GLC20 | 528(15.0) | 233.4(6.6 | GLC60 | 780(22.1) |

| 321(9.1) |

GLC25 | 618(17.5) | 277.5(7.9) | GLC80 | 1012(28.7) |

| 425(12) |

GLC30 | 526(14.9) | 197(5.6) | GLC100 | 1133(32.1) |

| 487(13.8) |

GLC35 | 575(16.3) | 240(6.0) | GLC125 | 1651(46.8) |

| 852(16.5) |

General Considerations

1.A generator set needs the engine to deliver 2 hp of energy to the alternator for every 1000 watts of electric output power (example: an 8000 watt generator needs the engine to deliver 16 hp of energy to the generator end).

2.An engine needs 10,000 BTU's of fuel energy per horsepower of engine power to provide a sufficient supply of fuel (example: a 16 Hp engine needs 160,000 BTU's of fuel energy for it to work properly). This fuel must be supplied to the regulator on the generator set at a pressure of 6 oz (11 inches of water column). To achieve this 6 oz. pressure in a L.P. System, you will normally have to reduce the tank pressure by means of a primary regulator or a regulator system of 2 or more regulators.

3.There are 2,516 BTU's in one cubic foot of Propane (LP Fuel). There are 1,096 BTU's in one cubic foot of Natural Gas.

4.There are 36.39 cubic feet in one gallon of Propane. There are 57.75 cubic feet in one gallon of Natural Gas.

5.There are 8.58 cubic feet per pound of Propane. There are 23.56 cubic feet per pound of Natural Gas.

6.When installing the piping for the gaseous fuel supply please refer to the pipe chart in Tables 3‐5 and 3‐6 to be sure you are using piping of significantly large size to deliver the necessary amount of fuel.

7.If copper tubing is used, it should be “K” or “L” having a minimum wall thickness of 0.032 inches. Black Iron Pipe is recommended but follow building codes for your area.

The following pamphlets are available from:

National Fire Protection Association (NFPA) P.O. Box 9101 Quincy, MA 02269

No. 37 - Combustion Engines

No. 54 - Gaseous Appliances and piping

No. 58 - Storage and handling LPV

3‐6 Receiving & Installation | MN2408 |