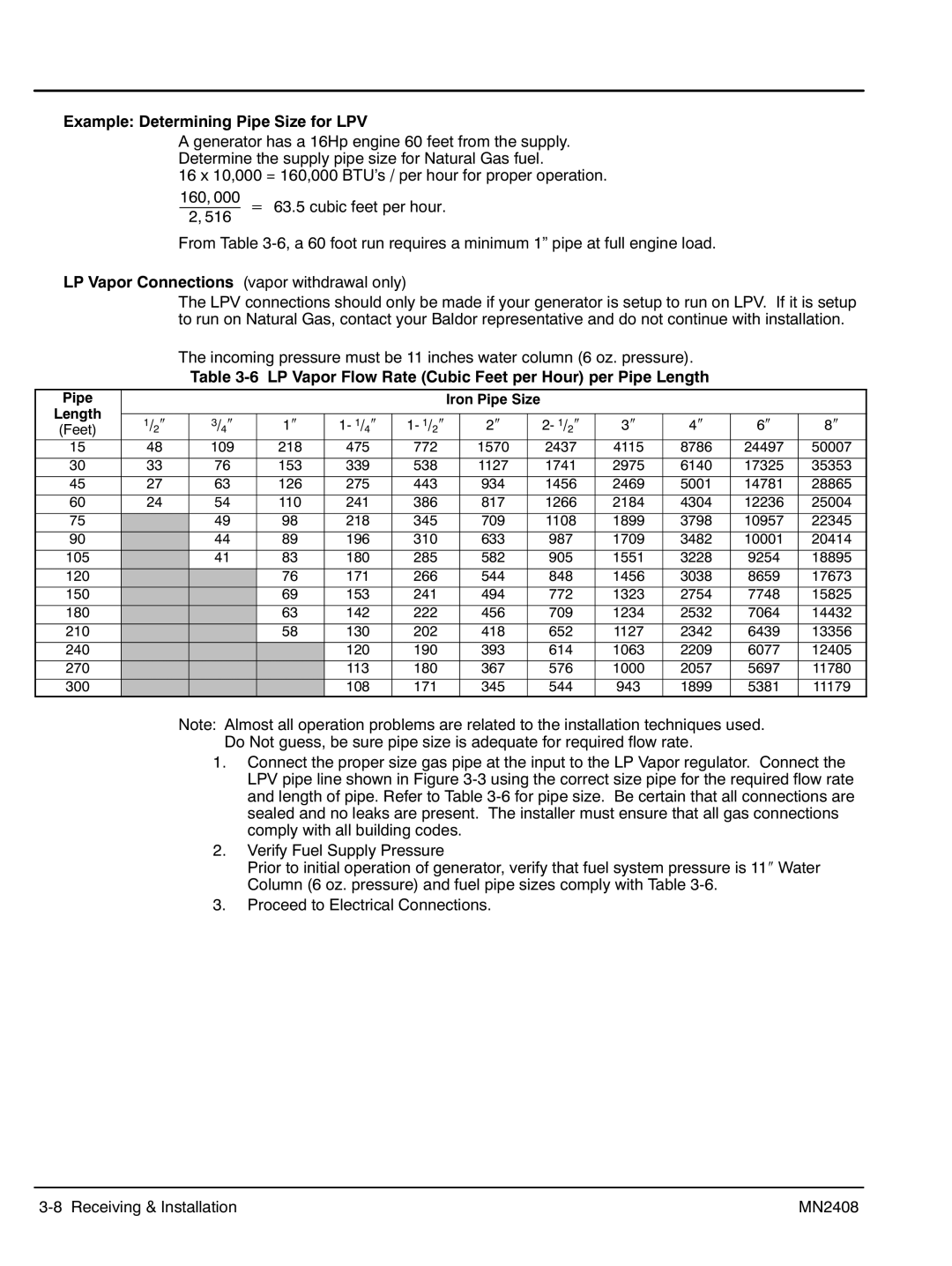

Example: Determining Pipe Size for LPV

A generator has a 16Hp engine 60 feet from the supply. Determine the supply pipe size for Natural Gas fuel.

16 x 10,000 = 160,000 BTU's / per hour for proper operation. 160, 000

2, 516

+ 63.5cubicfeetperhour.

From Table 3‐6, a 60 foot run requires a minimum 1” pipe at full engine load.

LP Vapor Connections (vapor withdrawal only)

The LPV connections should only be made if your generator is setup to run on LPV. If it is setup to run on Natural Gas, contact your Baldor representative and do not continue with installation.

The incoming pressure must be 11 inches water column (6 oz. pressure).

Table 3‐6 LP Vapor Flow Rate (Cubic Feet per Hour) per Pipe Length

Pipe |

|

|

|

|

|

|

| Iron Pipe Size |

|

|

|

|

| ||

Length |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1/ ″ | 3/ ″ | 1″ | 1- 1/ | ″ | 1- 1/ | ″ |

| 2″ |

| 2- 1/ ″ | 3″ | 4″ | 6″ | 8″ | |

(Feet) |

|

| |||||||||||||

2 | 4 |

| 4 |

| 2 |

|

|

|

| 2 |

|

|

|

| |

15 | 48 | 109 | 218 | 475 |

| 772 |

|

| 1570 |

| 2437 | 4115 | 8786 | 24497 | 50007 |

30 | 33 | 76 | 153 | 339 |

| 538 |

|

| 1127 |

| 1741 | 2975 | 6140 | 17325 | 35353 |

45 | 27 | 63 | 126 | 275 |

| 443 |

|

| 934 |

| 1456 | 2469 | 5001 | 14781 | 28865 |

60 | 24 | 54 | 110 | 241 |

| 386 |

|

| 817 |

| 1266 | 2184 | 4304 | 12236 | 25004 |

75 |

| 49 | 98 | 218 |

| 345 |

|

| 709 |

| 1108 | 1899 | 3798 | 10957 | 22345 |

90 |

| 44 | 89 | 196 |

| 310 |

|

| 633 |

| 987 | 1709 | 3482 | 10001 | 20414 |

105 |

| 41 | 83 | 180 |

| 285 |

|

| 582 |

| 905 | 1551 | 3228 | 9254 | 18895 |

120 |

|

| 76 | 171 |

| 266 |

|

| 544 |

| 848 | 1456 | 3038 | 8659 | 17673 |

150 |

|

| 69 | 153 |

| 241 |

|

| 494 |

| 772 | 1323 | 2754 | 7748 | 15825 |

180 |

|

| 63 | 142 |

| 222 |

|

| 456 |

| 709 | 1234 | 2532 | 7064 | 14432 |

210 |

|

| 58 | 130 |

| 202 |

|

| 418 |

| 652 | 1127 | 2342 | 6439 | 13356 |

240 |

|

|

| 120 |

| 190 |

|

| 393 |

| 614 | 1063 | 2209 | 6077 | 12405 |

270 |

|

|

| 113 |

| 180 |

|

| 367 |

| 576 | 1000 | 2057 | 5697 | 11780 |

300 |

|

|

| 108 |

| 171 |

|

| 345 |

| 544 | 943 | 1899 | 5381 | 11179 |

Note: Almost all operation problems are related to the installation techniques used.

Do Not guess, be sure pipe size is adequate for required flow rate.

1.Connect the proper size gas pipe at the input to the LP Vapor regulator. Connect the LPV pipe line shown in Figure 3‐3 using the correct size pipe for the required flow rate and length of pipe. Refer to Table 3‐6 for pipe size. Be certain that all connections are sealed and no leaks are present. The installer must ensure that all gas connections comply with all building codes.

2.Verify Fuel Supply Pressure

Prior to initial operation of generator, verify that fuel system pressure is 11″ Water Column (6 oz. pressure) and fuel pipe sizes comply with Table 3‐6.

3.Proceed to Electrical Connections.

3‐8 Receiving & Installation | MN2408 |