!CAUTION

1.Noise is generated from the drive, motor, and wiring. Take care that this noise does not cause malfunctions in peripheral sensors and equipment, otherwise accidents could occur.

(4)Control terminal arrangement, screw size, and tightening torque Figure

30A![]() 30B

30B ![]() 30C

30C ![]() FM

FM ![]() X1

X1 ![]() X2

X2 ![]() X3

X3 ![]() FWD

FWD ![]() REV

REV![]() CM

CM ![]() 11

11 ![]() 12

12 ![]() 13

13 ![]() C1

C1

Figure 2-3-7 Control terminal block arrangement

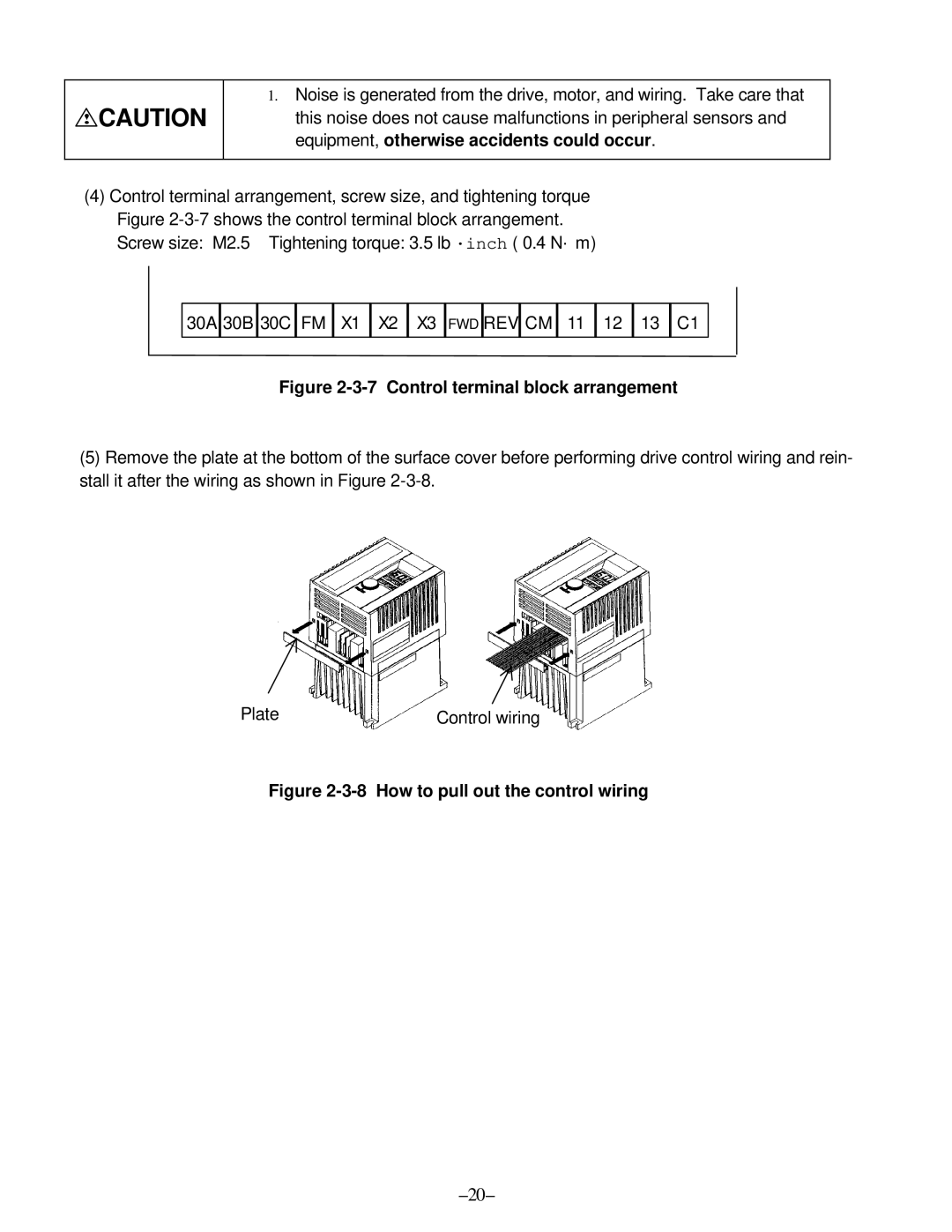

(5)Remove the plate at the bottom of the surface cover before performing drive control wiring and rein- stall it after the wiring as shown in Figure

Plate | Control wiring |