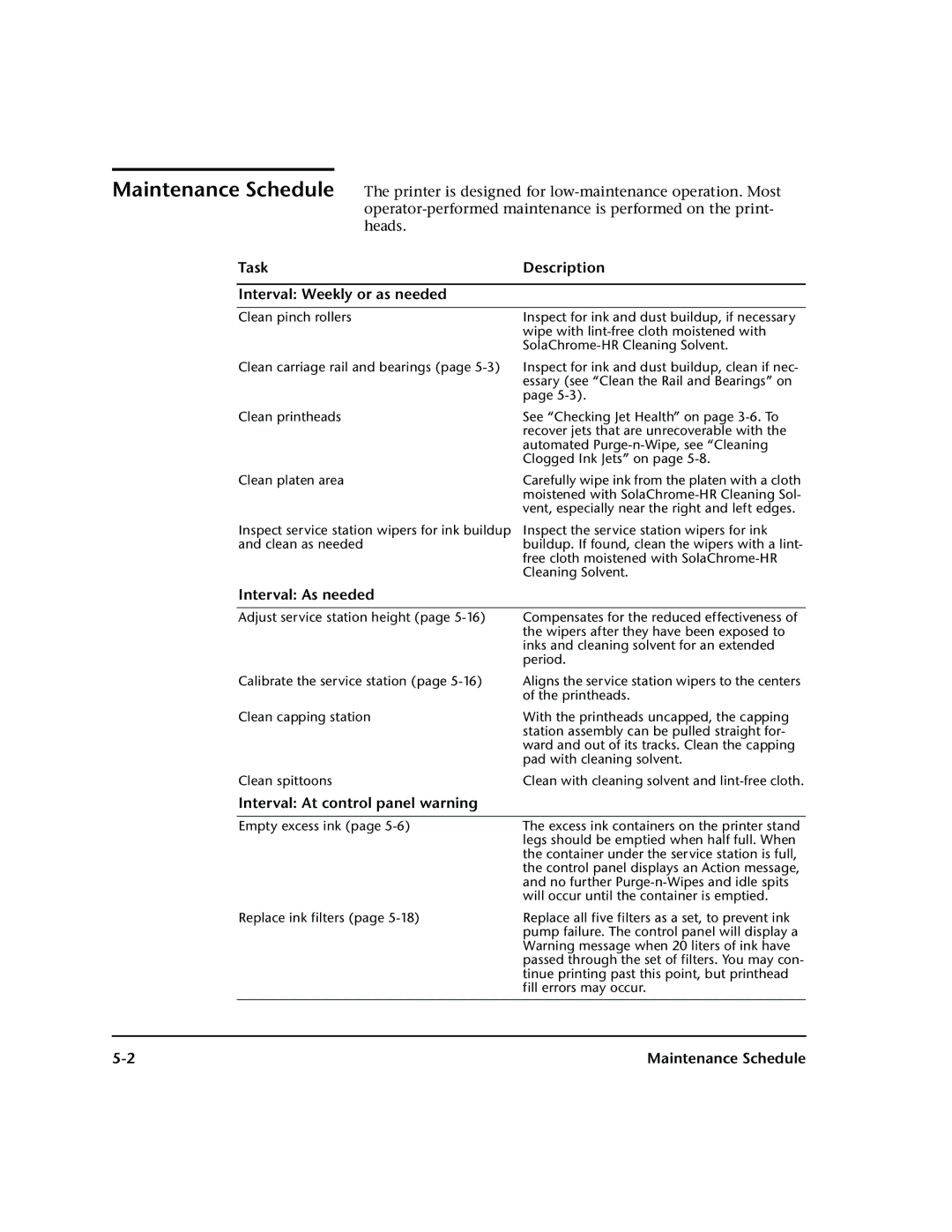

Maintenance Schedule The printer is designed for

Task | Description |

|

|

Interval: Weekly or as needed |

|

|

|

Clean pinch rollers | Inspect for ink and dust buildup, if necessary |

| wipe with |

|

Clean carriage rail and bearings (page

Clean printheads

Clean platen area

Inspect for ink and dust buildup, clean if nec- essary (see “Clean the Rail and Bearings” on page

See “Checking Jet Health” on page

Carefully wipe ink from the platen with a cloth moistened with

Inspect service station wipers for ink buildup and clean as needed

Inspect the service station wipers for ink buildup. If found, clean the wipers with a lint- free cloth moistened with

Interval: As needed

Adjust service station height (page

Calibrate the service station (page

Compensates for the reduced effectiveness of the wipers after they have been exposed to inks and cleaning solvent for an extended period.

Aligns the service station wipers to the centers of the printheads.

Clean capping station | With the printheads uncapped, the capping |

| station assembly can be pulled straight for- |

| ward and out of its tracks. Clean the capping |

| pad with cleaning solvent. |

Clean spittoons | Clean with cleaning solvent and |

Interval: At control panel warning

Empty excess ink (page 5-6)

Replace ink filters (page 5-18)

The excess ink containers on the printer stand legs should be emptied when half full. When the container under the service station is full, the control panel displays an Action message, and no further

Replace all five filters as a set, to prevent ink pump failure. The control panel will display a Warning message when 20 liters of ink have passed through the set of filters. You may con- tinue printing past this point, but printhead fill errors may occur.

Maintenance Schedule |